Ever felt that primal urge to fix, create, or just plain *make* something with your own two hands? There’s a certain magic to fusing metal, the satisfying sizzle of an arc, the shower of sparks, and the undeniable feeling of accomplishment when a broken piece becomes whole again, or an idea takes solid, metallic form. Welding isn't just for industrial giants; it's a fantastic skill for the everyday DIY enthusiast, artist, or anyone who enjoys the satisfaction of tangible creation and repair. Think of it: fixing that wobbly gate, repairing a trusty lawnmower, building a custom workbench, or even crafting unique metal art for your home. It’s about empowerment, saving a fortune on repairs, and bringing your creative visions to life.

When you decide to dive into the fiery world of welding, one of the first questions you’ll face is: Wire Welder vs. Stick Welder? It’s like choosing between a smooth, agile sports car and a rugged, all-terrain truck – both get you where you need to go, but they offer very different experiences and excel in different conditions. Let's break down these two titans of metal fusion.

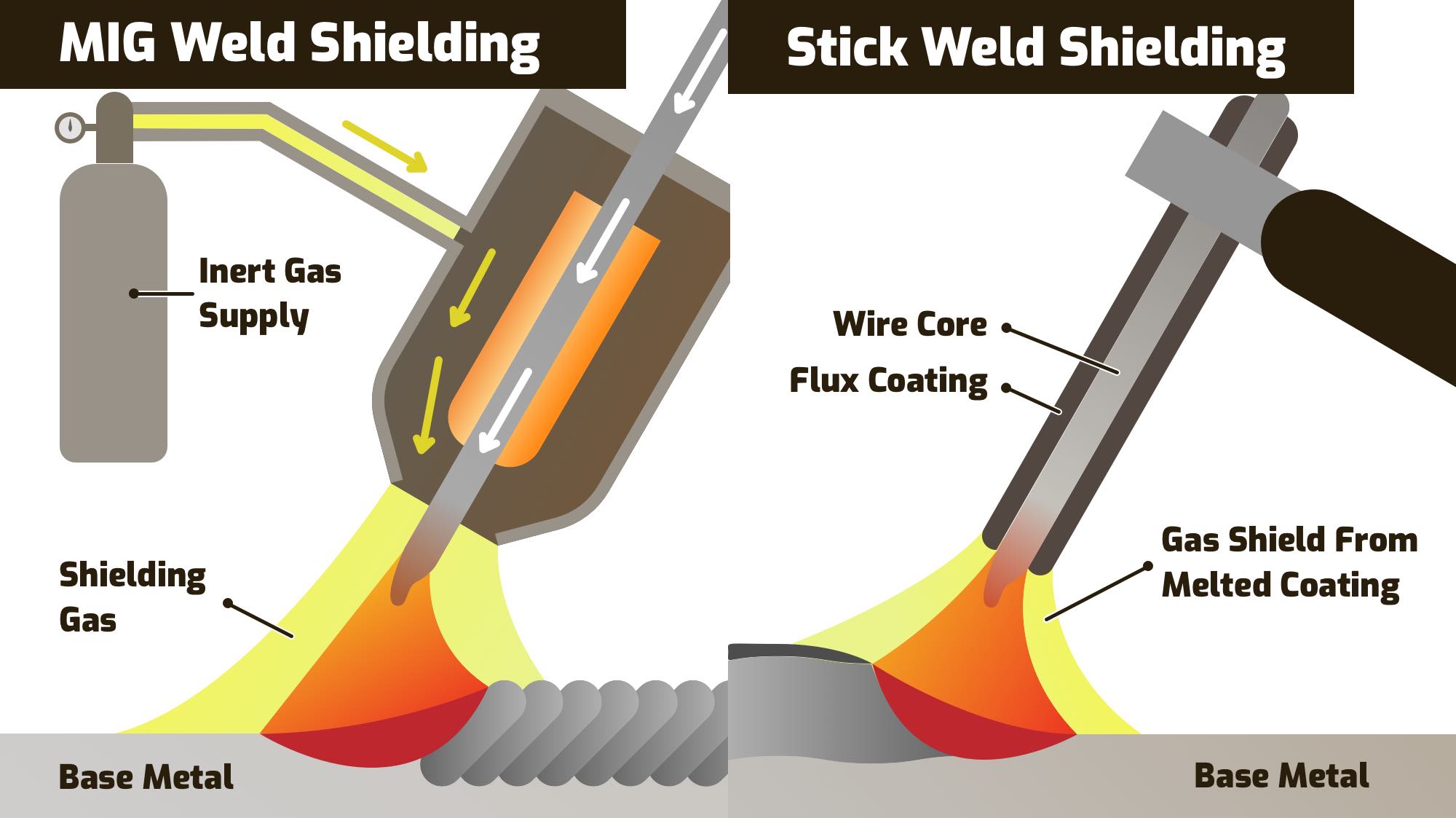

First up, the Wire Welder, often known as MIG (Gas Metal Arc Welding) or Flux-Core welding. This is often the go-to for beginners, and for good reason. Imagine a hot glue gun for metal; you pull a trigger, and a continuous wire electrode feeds out, melting into a beautiful, consistent bead. MIG welding, with its shielding gas, produces incredibly clean welds with minimal spatter, making your finished product look professional faster. It’s fantastic for thinner metals, automotive bodywork, and projects where aesthetics are key. If you're looking for speed and ease of learning, especially for home repairs like fencing, small structural fixes, or building custom shelves, a wire welder is an excellent choice. It’s literally a "point and shoot" experience once you get the hang of basic settings.

Then we have the Stick Welder, or SMAW (Shielded Metal Arc Welding). This is the rugged veteran of the welding world. Instead of a wire spool, you use individual stick electrodes coated with flux. As the stick burns, the flux creates a gas shield, protecting your weld from contaminants. Stick welding has a steeper learning curve; you need to manage the arc length and electrode angle, and you'll often have to chip away slag (the hardened flux) after each weld. However, don't let that deter you! Stick welders are incredibly forgiving on dirty, rusty, or painted metals, making them perfect for farm equipment, heavy structural work, or outdoor repairs where windy conditions would blow away the shielding gas of a MIG welder. They are also often more portable and can weld thicker, heavier materials with surprising ease. If you're tackling robust projects like trailer repairs, gate hinges, or anything that needs to withstand serious abuse, the power and portability of a stick welder are hard to beat.

So, how can you enjoy this sizzling hobby more effectively? Safety first! Always wear your personal protective equipment (PPE) – a good auto-darkening helmet, thick gloves, a welding jacket, and closed-toe shoes are non-negotiable. Beyond safety, the biggest tip is: practice, practice, practice! Start with scrap metal, experiment with different settings, and watch plenty of instructional videos. Don't be afraid to make ugly welds; every bad bead is a lesson learned. Choose the welder that best suits your typical projects. If you’re mostly working on lighter, cleaner metals indoors, a wire welder will bring you immense joy. If you foresee tackling tough, outdoor, or heavy-duty repairs, the stick welder is your steadfast companion. Ultimately, both types of welders unlock a world of creative possibilities and practical problem-solving. Get started, embrace the sparks, and build something awesome!