Alright, buckle up buttercups! We're diving headfirst into the wonderful world of Lean Philosophy! And don't worry, it's not about crash dieting (though decluttering your life might be a happy side effect). Think of it more like Marie Kondo, but for your entire business (or even your sock drawer, if you’re feeling ambitious).

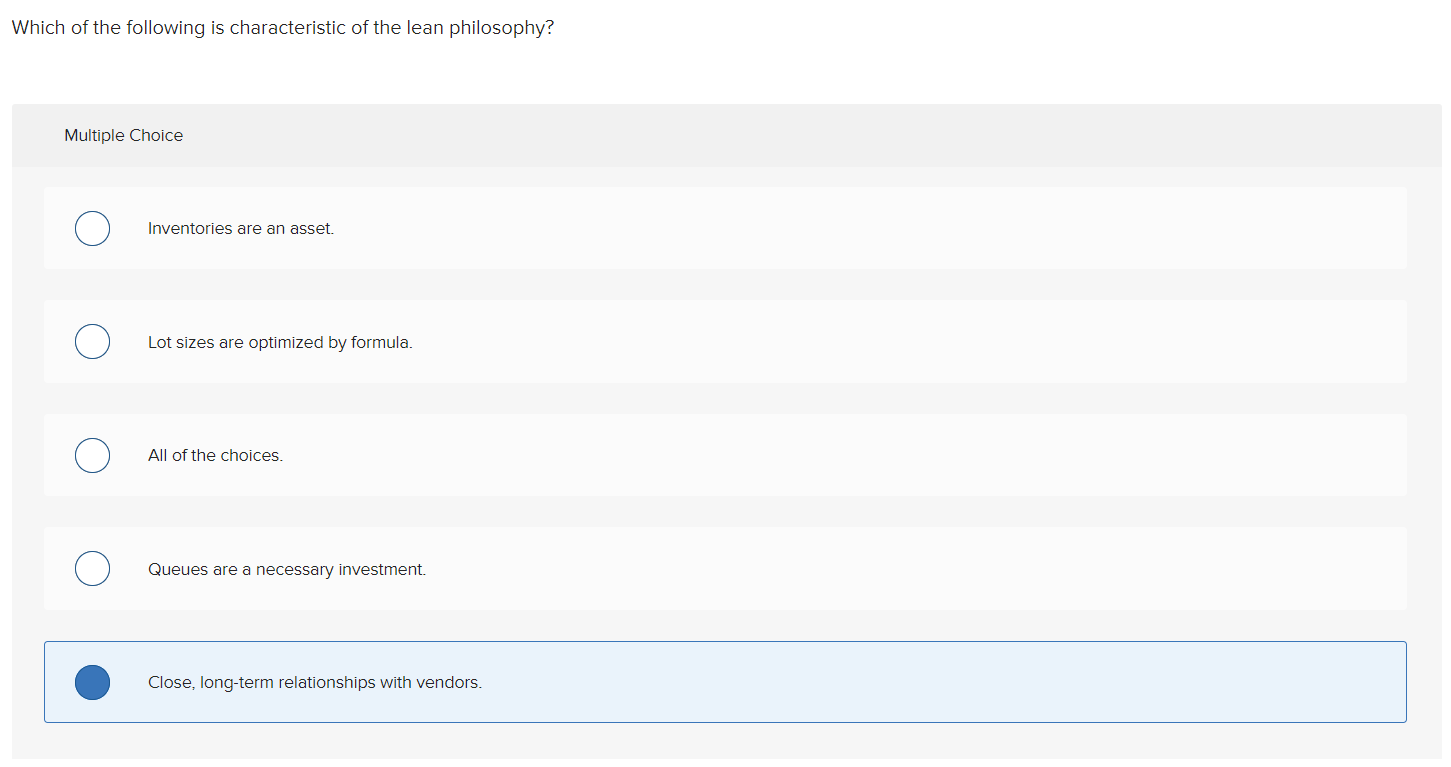

So, what exactly makes something Lean? Let's say you're trying to figure out which of these is a classic Lean move:

- A) Hoarding enough printer paper to build a fort (just in case!).

- B) Always blaming the intern when things go wrong.

- C) Continuously looking for ways to make things better, even if they seem "good enough" already.

- D) Creating twenty different reports that no one actually reads.

The answer? C! Absolutely C! Let's break it down, shall we?

The Quest for Continuous Improvement (aka, Never Settle!)

Lean Philosophy is all about continuous improvement – in fancy terms, it’s called Kaizen. That’s Japanese for “change for better” or “improvement”. Think of it like this: you bake a cake. It's... okay. Edible. Your cat seems mildly interested. Lean thinking says, "Okay, how can we make this cake EPIC?" Maybe less salt, more frosting, a tiny disco ball on top? (Okay, maybe not the disco ball… unless?). The point is, you're always looking for ways to make things better, even if they're already pretty darn good. This is a core tenet of Lean. Striving for perfection, knowing you'll probably never *quite* get there, but having a blast trying.

Eliminating Waste (aka, the "Stuff We Don't Need" Audit)

One of the biggest things in Lean is chopping out the unnecessary stuff. This could be wasted time, wasted materials, wasted effort, or even wasted opportunities. Imagine you're making sandwiches. If you make 100 sandwiches and 50 end up in the trash because they’re stale, that’s a HUGE waste! Lean thinking would ask: "Why are we making so many? How can we make them fresher? Can we donate the extra ones? Maybe we can make the sandwiches the size of donuts!". Okay, maybe not the donut-sized sandwiches, unless you're into that sort of thing. The key is to identify and eliminate the waste. This idea applies everywhere, from building cars to writing software to, yes, even making sandwiches!

Eight Deadly Wastes – the Villains of Efficiency!

Lean identifies eight main types of waste (often referred to as "the 8 wastes"): Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing. Learning to spot these guys is like gaining superpowers! You'll see them lurking in every corner, waiting to steal your time and resources. Lean helps you become a waste-busting superhero!

Respect for People (aka, Everyone's Got a Brilliant Idea!)

This one’s huge! Lean Philosophy isn’t just about processes and efficiency; it's about valuing the people who are *doing* the work. It means listening to their ideas, empowering them to make improvements, and treating them with respect. Think of it this way: if you’re making those sandwiches and the sandwich-maker says, “Hey, what if we used sourdough instead of white bread? It tastes better and holds the fillings better!”, you listen! They're the experts! Lean emphasizes that the people closest to the work often have the best ideas for improving it. Lean believes that creating a collaborative and supportive environment unlocks the full potential of the team.

Lean isn't about working harder; it's about working smarter. And making better cakes...or sandwiches... or spaceships. Whatever floats your boat!

So, there you have it! Lean Philosophy in a nutshell. It's about continuous improvement, eliminating waste, and respecting people. It's a journey, not a destination, and it's a whole lot more fun than hoarding printer paper.

Remember options A, B, and D? They represent everything Lean actively tries to avoid!