Okay, so you want to talk about welding cast steel to regular steel, huh? Pull up a chair, grab a metaphorical coffee, because this isn't just slapping two pieces of metal together and calling it a day. Oh no, my friend. This is where things get a little… interesting.

You see, when we talk about steel, it's like saying "food." There's salad, and then there's a five-course meal with fancy sauces. Both are food, but vastly different, right? Same with steel. Regular steel, the kind you often find in beams or plates, is usually pretty uniform, predictable. But cast steel? That's a different beast altogether.

Why the fuss? What makes cast steel such a diva?

Well, cast steel starts its life as molten metal poured into a mold. It cools, it solidifies, and often, it ends up with a grain structure that's a bit more… haphazard. It can have internal stresses, maybe a few more impurities lurking about, and it generally doesn't appreciate sudden temperature changes. It's a bit like a grumpy old man who hates surprises.

So, when you try to introduce that grumpy old man to a young, spry piece of mild steel with a super hot welding arc, you can imagine the potential for drama. The main goal? To avoid that dreaded word: cracking. Because nothing breaks a welder's heart faster than a beautiful bead that suddenly goes "snap!"

Step 1: Know Thy Metal (Or At Least Try To)

First things first, are you absolutely, positively sure it's cast steel? Sometimes folks confuse it with cast iron, and that's a whole other can of worms, my friend. Cast iron is *way* more brittle and finicky. A quick spark test can give you clues – cast steel usually throws a brighter, more branching spark than cast iron. When in doubt, assume the worst, right? Or, you know, ask an expert.

Cleanliness is Next to Weld-liness (Seriously)

This isn't rocket science, but it's often overlooked. Any grease, paint, rust, scale, or general crud on either piece? Get rid of it. Grind it, wire brush it, whatever it takes. You want a clean, shiny surface. Impurities are the enemy of strong welds. Period. End of discussion.

Preheat: Your Best Friend for Cast Steel

Alright, this is where the magic starts. For cast steel, you almost always want to preheat. And I mean a good, thorough preheat. We're talking 200-400°F (or even higher, depending on the specific alloy). Why? To slow down the cooling rate after welding and to reduce the thermal shock. Remember our grumpy old man? He likes to warm up slowly. A sudden blast of heat and then rapid cooling is just asking for a tantrum (read: cracks).

Use a rosebud torch, an oven, even a heating blanket if you're fancy. Just get those metals nice and toasty. And keep checking the temperature with a temp crayon or IR thermometer. Don't eyeball it – this isn't a guessing game.

Choosing Your Weapon: The Filler Metal

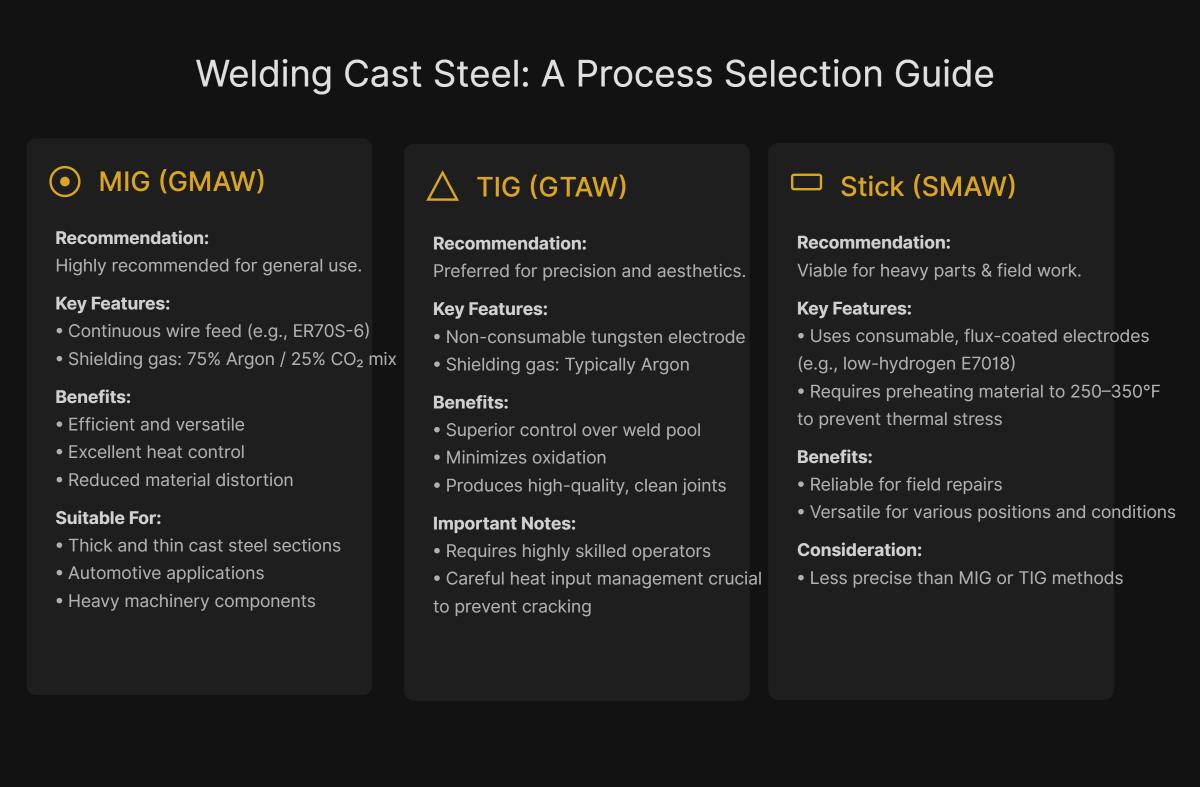

This is crucial. You can't just grab any old stick or wire. You need something that's friendly to both materials, something that can bridge the gap in their personalities. For cast steel to mild steel, a lot of welders lean towards nickel-based electrodes (like an ENiFe-CI for stick) or certain stainless steel wires (like 309L) if you're MIG/TIG welding. These fillers are more ductile and can handle the differing expansion and contraction better than standard mild steel fillers.

They act as a kind of flexible mediator between the two different materials, absorbing some of the stress. Think of it as the diplomat of the weld joint.

Technique: Slow and Steady Wins the Race

Once you're preheated and have your perfect filler, it's about technique. Keep your passes short and sweet. Don't try to lay down one monster bead. Small, controlled stringers are your friend. Overheating either material is a big no-no, especially the cast steel side. Some even recommend a little peening (gently hammering the hot weld bead) between passes to relieve stress, but that's a more advanced move.

And when you're done? Don't just toss it aside to cool in the cold shop air. You want a slow cool down. Cover it with a welding blanket, bury it in sand, or even stick it back in a preheating oven and let it slowly come down to room temp. This post-weld heat treatment (or lack thereof) is just as important as the preheat in preventing those nasty cracks.

So, Can It Be Done?

Absolutely! It's not a walk in the park, but with the right prep, the right filler, and a healthy dose of patience, welding cast steel to regular steel is totally achievable. It just demands a bit more respect, a bit more attention to detail, and maybe a few less shortcuts than welding two pieces of plain old mild steel together.

Just remember: Preheat, proper filler, and slow cooling. Get those three things right, and you're well on your way to a successful, crack-free weld. Go forth and weld, my friend!