There's a special kind of magic in taking two separate pieces of metal and, with a flash of light and a hum of power, fusing them into one strong, seamless whole. It’s the satisfying click of a puzzle piece fitting perfectly, but on an industrial scale. Whether you're a seasoned fabricator, a passionate DIY enthusiast, or simply someone who appreciates the beauty of things made to last, the world of welding holds an undeniable allure. And when it comes to precision, control, and truly beautiful craftsmanship,

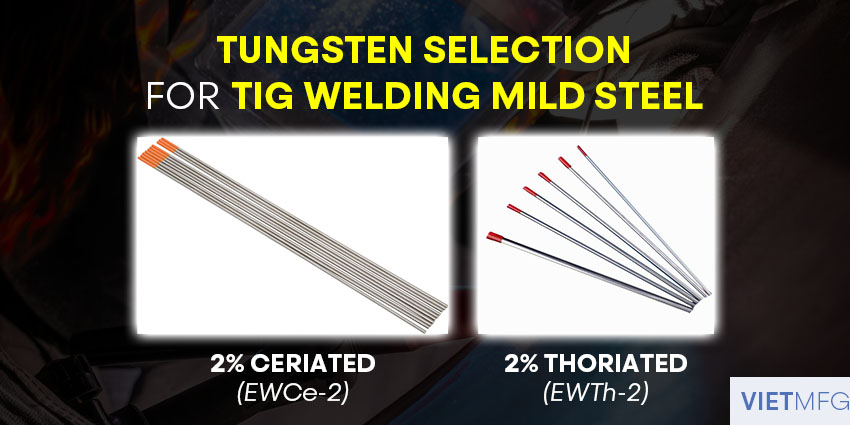

For those venturing into TIG welding mild steel, understanding the role of your tungsten electrode is absolutely crucial. Think of it as the maestro's baton for your arc. This isn't just about sticking metal together; it's about creating joints that are not only incredibly strong and durable but also aesthetically pleasing, with minimal spatter and a clean finish. In everyday life, this translates to everything from repairing a beloved garden gate that’s seen better days, building custom shelving units that perfectly fit your unique space, or even fabricating robust frames for your next creative project. The right tungsten for mild steel ensures a

So, where does this often-unsung hero, the tungsten electrode, shine brightest? You'll find its fingerprints all over our modern world. Imagine the intricate metalwork on a decorative railing, the custom exhaust system on a classic car, or even the robust framework of a utility trailer – all likely benefited from the clean, controlled arc delivered by a properly chosen tungsten. In the home workshop, it's invaluable for mending a broken tool handle, constructing bespoke metal furniture, or even tackling more ambitious automotive repairs. Professionals rely on it daily for everything from pipe welding to fabricating industrial components, where

To truly enjoy the art of TIG welding mild steel, and ensure your tungsten is performing its best, here are a few practical tips. Firstly, for mild steel, you’ll typically want a