Alright, grab your coffee, maybe a donut, because we're gonna chat about something that's super crucial if you're into TIG welding mild steel: those humble little rods. You know, the ones that look like shiny metal pencils? Yeah, those guys!

Ever been at your welding bench, torch in hand, and suddenly realize you're staring at two pieces of metal that desperately want to be one, but they just... aren't? That's where our little heroes come into play. They're the glue, the secret sauce, the magical ingredient that turns a hot puddle into a glorious, strong joint. Without them? You'd just be making pretty little puddles and a lot of heat, not much else! Kinda like trying to bake a cake without flour, right?

What Are We Even Talking About?

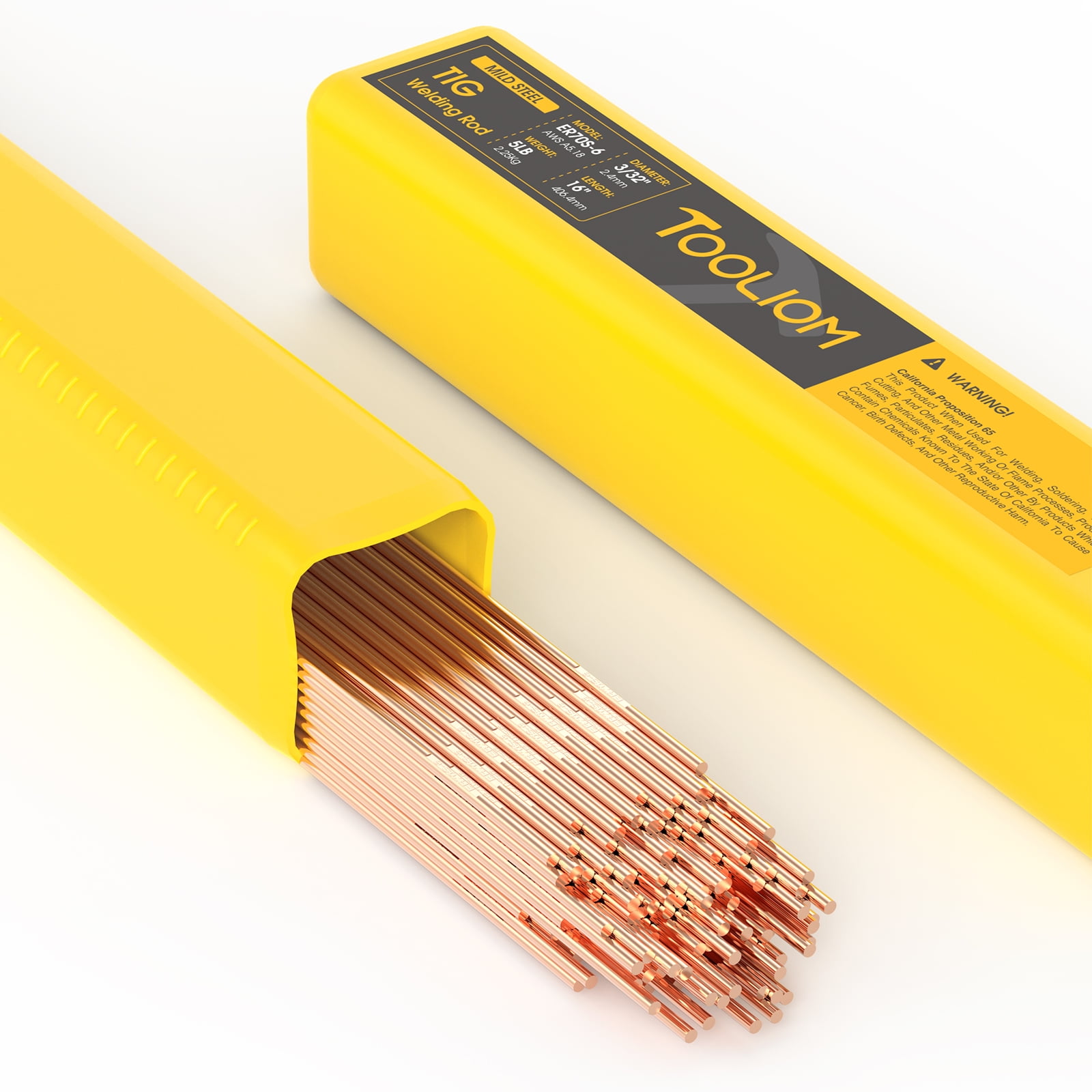

So, we're specifically focusing on mild steel TIG welding rods. These aren't just any old metal sticks; they're formulated to melt smoothly into your mild steel base material, creating a weld that's not only strong but also often looks pretty darn good. You might hear them called "filler wire" or "filler metal," but "rods" just feels more... hands-on, doesn't it?

The most common types you'll bump into are probably ER70S-2 and ER70S-6. Sounds like a secret agent code, doesn't it? Don't sweat the numbers too much, but essentially, they tell you a bit about what's inside.

ER70S-2: Think of this as your go-to for cleaner material. It's got deoxidizers in it, which helps keep your weld puddle nice and happy, especially if your base metal is squeaky clean. It's like giving your weld a little extra polish from the inside out.

ER70S-6: This one's a bit more forgiving. It has even more deoxidizers, making it great for when your mild steel isn't quite as pristine. Maybe there's a tiny bit of rust, some mill scale, or just not perfectly prepped. The S-6 is like the friendly, adaptable cousin, always ready to lend a hand, even if things aren't perfect.

And then there are the sizes! They come in different diameters, from super skinny (think pencil lead) to quite chunky. Picking the right size is kinda like choosing the right crayon for your drawing – a fine point for detail, a broad one for filling in big areas. Generally, you want a rod size that's comparable to the thickness of the metal you're welding. Too big, and it's like trying to jam a log into a tiny campfire. Too small, and you'll be feeding it like a hungry baby bird!

Choosing Your Weapon (I Mean, Rod)

Okay, so how do you pick the right one for your masterpiece? Mostly, it's about what you're welding to. Mild steel? Mild steel rods. Simple, right? Don't go trying to weld stainless with mild steel rods; that's like trying to put a square peg in a round hole – it just won't work, trust me. You'll end up with a brittle, ugly mess, and probably a headache.

For most everyday shop tasks, especially on clean material, an ER70S-2 will treat you right. If you're working with something a little less-than-perfect, or maybe just want a bit more wiggle room, the ER70S-6 is your pal. It's like having a trusty multi-tool versus a precision instrument – both have their place!

The Dance: Using Those Rods

This is where the magic really happens. You've got your TIG torch in one hand, sparking away, creating that beautiful molten puddle. And then, delicately, gracefully, you feed the rod into that puddle with the other hand. It's a delicate ballet of heat, feed, and timing.

I remember my first few tries. The rod would just stick to the tungsten. Ugh! So frustrating! Felt like I had two left hands and zero coordination. Or I'd feed it too fast and end up with a blobby mess, or too slow, and watch my base metal melt away faster than ice cream on a hot day. The struggle is real, folks!

A little tip from your friendly neighborhood welding enthusiast: keep 'em clean! Seriously, those shiny rods like to stay shiny. Grease, dirt, fingerprints – big no-nos. They can introduce contaminants into your weld, making it weak and full of porosity. Think of it as prep for a gourmet meal; you wouldn't use dirty ingredients, would you? Nope! So wipe 'em down if you've been handling them a lot, or just store them properly in a nice, dry tube.

The Sweet Satisfaction

But oh, when you get that perfect bead! Those tiny little ripples, consistent, strong, beautiful. It's like a tiny victory dance in your garage. You just fused metal, man! How cool is that? It's a testament to your skill, your patience, and those amazing mild steel TIG welding rods doing their job flawlessly.

So next time you're gearing up for some mild steel TIG, give a little nod to those unsung heroes, the welding rods. They're small, often overlooked, but mighty. And with a bit of practice and the right choice, they'll help you create some seriously impressive, super-strong stuff. Now, go forth and weld! What project are you tackling next?