Okay, gather 'round, folks, because I've got a little confession. Not too long ago, I was feeling pretty smug about my MIG welding skills. Mild steel? No problem. Aluminum? With the right setup, I was practically a wizard. Then came the stainless steel project. A shiny, beautiful, challenging beast of a metal.

I figured, "Hey, MIG is MIG, right? Just swap out the wire, maybe tweak the settings a bit." So, I loaded up some 308L wire, set my trusty old C25 (75% Argon, 25% CO2) gas, and went for it. Oh, boy. What came out was… well, it was certainly *a* weld. But it was ugly. Like, really, truly, deep-fried-boot-lace ugly. Black, sooty, pitted, and honestly, kinda crunchy looking.

My ego took a beating that day, let me tell you. I blamed my technique, the phase of the moon, probably even that squirrel that kept chattering at me from the oak tree. But then, a more experienced buddy strolled by, took one look at my sad, pathetic bead, and then glanced at my gas bottle. He just shook his head, a little smirk playing on his lips. "You're trying to MIG stainless with C25, aren't ya?" he asked, not really needing an answer.

And that, my friends, was my "aha!" moment. It wasn't just my technique (though it could always use work, let's be real). It was the gas. Specifically, the *wrong* gas. It’s a bit like trying to bake a gourmet cake with salt instead of sugar. You might have all the right ingredients otherwise, but that one wrong thing ruins everything. And for stainless steel MIG welding, gas is everything.

Why Stainless Steel Is So Picky

You see, stainless steel is fancy. It gets its awesome corrosion resistance from a super thin, protective layer of chromium oxide that forms on its surface. When you weld it, you're introducing heat and, potentially, atmospheric contaminants. That protective layer is super sensitive to heat and carbon. Introduce too much carbon (from, say, CO2 gas), and that chromium gets all buddy-buddy with the carbon, forming chromium carbides.

When that happens, the chromium is no longer available to fight rust in those areas. This is called "carbide precipitation," and it turns your fancy, rust-resistant stainless into… well, slightly less fancy, rust-prone stainless. Not ideal for that boat railing or kitchen counter you just spent a fortune on, right?

The Wrong Gas: A Stainless Steel No-Go

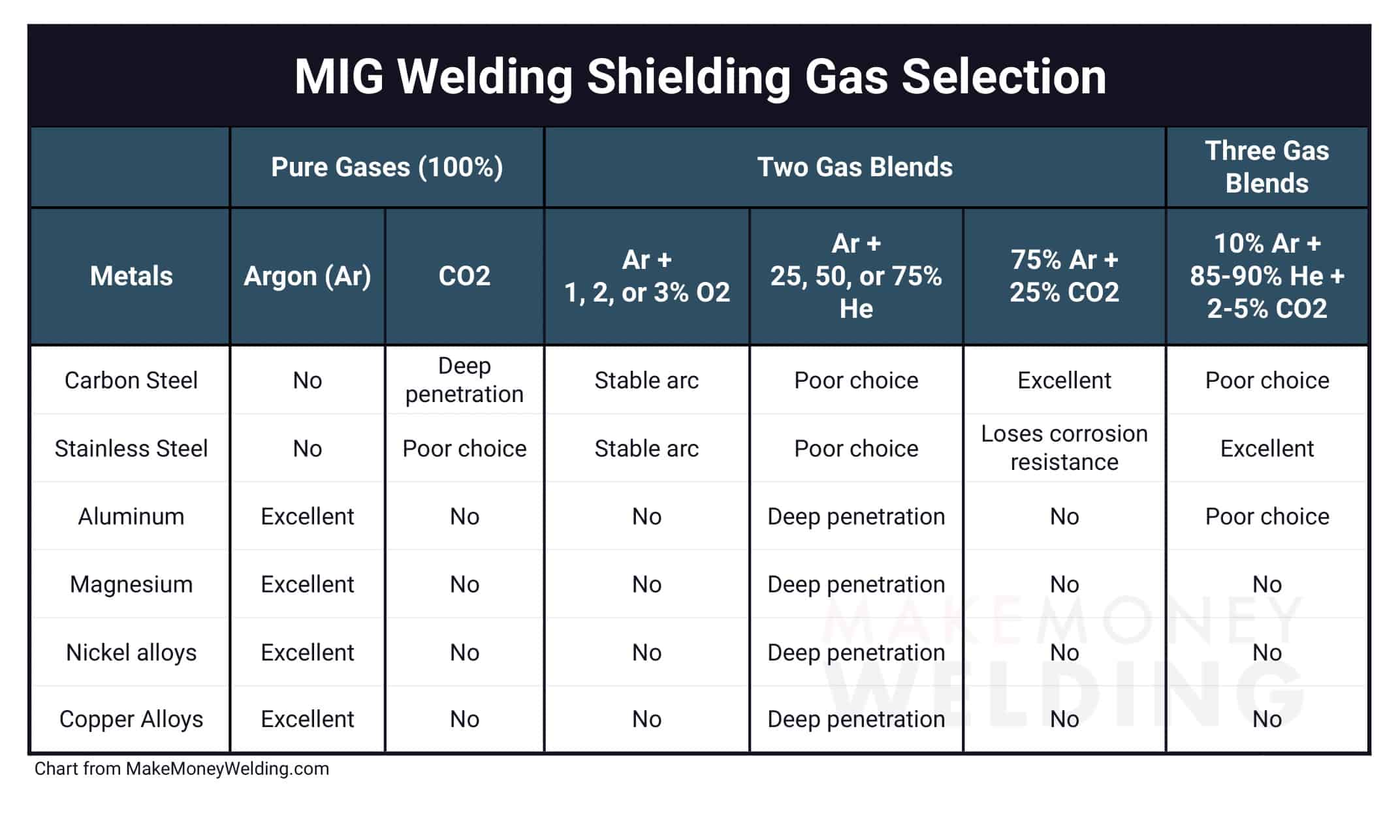

So, back to my initial blunder. C25 (75% Argon / 25% CO2) is a fantastic gas for mild steel. The CO2 helps with penetration, arc stability, and gives a decent bead profile. But for stainless? It's a disaster waiting to happen. That 25% CO2 is way too much carbon for stainless to handle, leading to that ugly, sooty, carbide-laden mess I experienced.

You want to keep that chromium happy, remember? So, we need to drastically cut down on carbon, or eliminate it entirely.

The Right Gases: Your Stainless Steel Buddies

This is where things get interesting, and thankfully, much prettier. When it comes to MIG welding stainless, you've got a couple of main players that'll treat your metal right:

1. Argon/Oxygen (Ar/O2) – The Workhorse

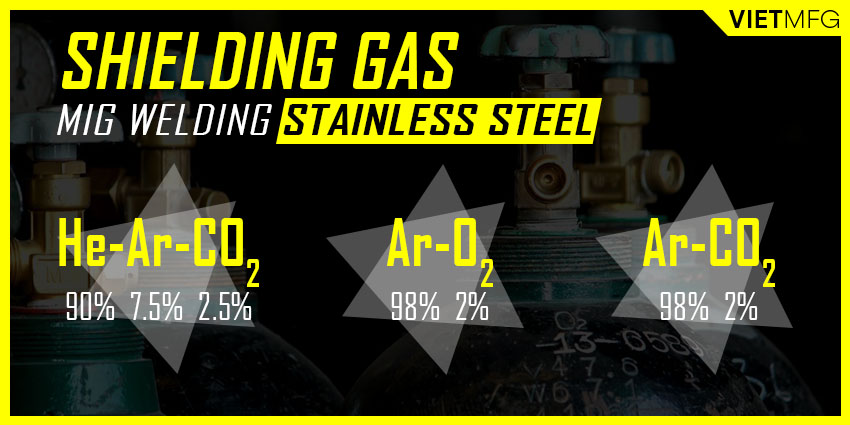

This is probably the most common and versatile choice for MIG welding stainless steel. Typically, you'll see mixes like 98% Argon / 2% Oxygen. Sometimes 1% or 3% Oxygen, but 2% is a sweet spot for many applications.

Why oxygen? Oxygen, in small amounts, helps stabilize the arc, improves the "wetting" action of the weld puddle (meaning it flows out nicely), and gives you a much smoother, cleaner bead than pure argon would. Crucially, it doesn't introduce nearly as much carbon as CO2, so your chromium layer stays mostly intact. Think of it as a gentle coaxing agent for the weld pool, rather than a harsh push.

This is your go-to for general fabrication, thinner materials, and when you want a nice, clean finish.

2. Tri-Mix (Argon/Helium/CO2) – For The Heavy Hitters

Now, if you're working with thicker stainless sections, or if you need a bit more heat and deeper penetration, you might want to look at a Tri-Mix gas. A common formulation might be something like 90% Argon / 8% Helium / 2% CO2.

Here's the breakdown:

- Argon: Still the primary shielding gas.

- Helium: This is the heat-booster. Helium has a higher ionization potential than argon, which means it helps generate more heat in the arc. This translates to better penetration and a wider, flatter bead profile, which is great for thicker material. It also helps with wetting.

- CO2 (very small amount): Just like with the Argon/Oxygen mix, a tiny bit of CO2 (usually 0.5% to 2%) helps with arc stability and wetting. It's a delicate balance to get these benefits without introducing too much carbon.

The downside? Helium isn't cheap, so your gas bill will definitely reflect this choice. But for critical applications or thicker stainless, it can be totally worth the investment. Your welds will thank you, and your future self won't be grinding out porosity, trust me on this one.

Pure Argon? Usually Not for MIG

You might be wondering, "What about pure argon?" While excellent for TIG welding stainless (where there's no filler wire to stabilize the arc), it's generally not ideal for MIG. Why? Without that tiny bit of oxygen or CO2, pure argon often results in a very ropey, convex, and unstable weld bead with poor wetting. It just doesn't behave well in a MIG environment.

The Takeaway: Don't Skimp on Gas!

So, what's the moral of this bubbly tale? When it comes to MIG welding stainless steel, do not cheap out on your shielding gas. It's as crucial as your wire and your machine settings. Using the wrong gas can turn a potentially beautiful, strong, corrosion-resistant weld into a weak, ugly, rust-prone mess.

Always double-check your gas type before you start your project. Experiment with different mixes if you can, and see what works best for your specific application and desired finish. Your stainless steel creations (and your pride!) will be all the better for it.

Now, if you'll excuse me, I'm off to finally fix that rusty old bird feeder. With the *right* gas, of course. No more ugly welds for this guy!