Alright, settle in, grab another coffee. I’m about to tell you something you probably didn't expect to hear about Kansas City. You know KC for its glorious, smoky BBQ, its rich jazz history, and maybe, just maybe, for being the heartland of America. But did you know it’s also a hotbed for... wait for it... laser tube cutting?

Yeah, I know. It sounds like something straight out of a sci-fi movie where a rogue robot is making abstract art from plumbing pipes. But trust me, it’s a real thing, and it's surprisingly *cool*.

What in the World is Laser Tube Cutting?

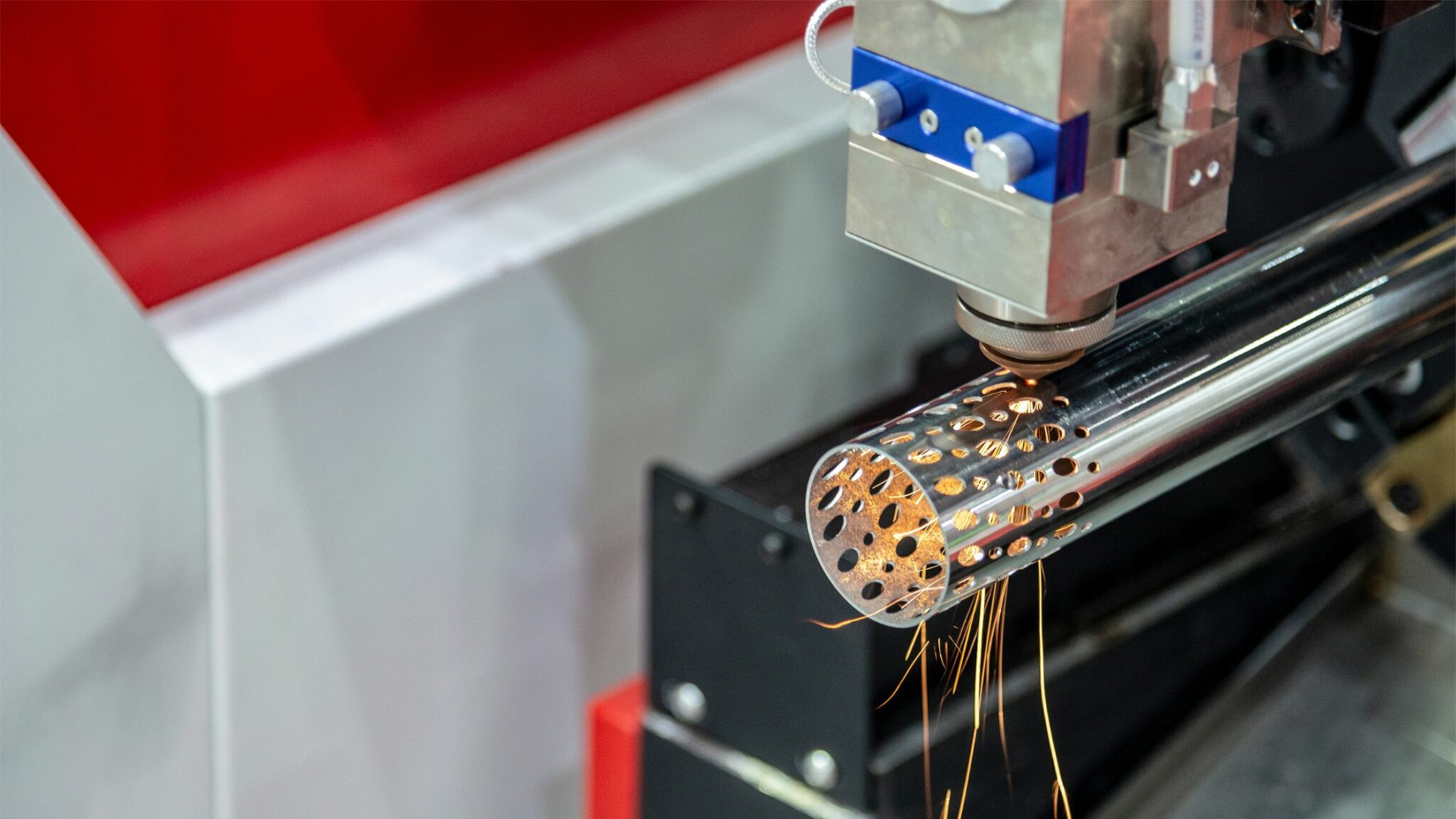

Okay, let’s demystify this without getting bogged down in engineer-speak. Imagine you’ve got a piece of metal tubing – not your toothpaste tube, but more like a pipe, a rectangular hollow section, or an angle iron. Now, imagine you need to cut that tube into a super specific, often intricate, shape. Maybe you need a perfect hole here, a complex slot there, or to slice it into a bizarre, multi-faceted end piece.

Before lasers swooped in like technological superheroes, you’d be looking at a whole bunch of tedious, noisy, and often imprecise methods: sawing, drilling, punching, grinding. It was like trying to sculpt a masterpiece with a hammer and chisel.

Enter the laser. Specifically, a high-powered industrial laser. This isn't your cat's pointer, folks. We’re talking about a focused beam of light so intense, it can slice through steel like a hot knife through butter. And it does it with a level of precision that would make a surgeon blush.

Why Lasers and Why Tubes?

So, why tubes specifically? Well, tubes are the unsung heroes of countless structures and products. They’re in your car’s chassis, your building’s framework, your furniture, even that fancy trellis in your garden. The ability to cut tubes with such accuracy opens up a whole new world of design and manufacturing possibilities. No more wrestling with awkward angles or making multiple passes.

And why Kansas City, you ask? Good question! KC has always been a manufacturing hub. We build stuff here, from massive machinery to intricate parts. Our innovative spirit, combined with a central location, makes us a natural fit for advanced manufacturing techniques. Plus, let's be honest, who *wouldn't* want a city known for its BBQ also being a leader in space-age metalwork?

The "Magic" Behind the Beam

How does it actually work? Picture this: a powerful laser beam, often generated from fiber optics, is focused to an incredibly tiny point. This concentrated light creates intense heat, effectively vaporizing the metal in its path. All this happens under the watchful eye of a computer, which is running a program designed by an engineer. It’s like a super-smart robot with an incredibly steady hand and a lightsaber for a finger.

The tube is rotated and moved with incredible accuracy, allowing the laser to cut along any axis and create any shape imaginable. We’re talking about cuts so clean, you often don't need any post-processing – no burrs, no rough edges. It’s like the metal was born that way.

What Are They Making in KC with These Things?

This is where it gets really interesting! Because of this technology, Kansas City businesses are cranking out some seriously cool stuff:

- Architectural Wonders: Imagine custom-designed metal railings for a new building downtown, intricate decorative panels, or structural supports cut to perfect specifications.

- Industrial Giants: Parts for heavy machinery, agricultural equipment, and even components for the transportation sector. Think complex exhaust systems or chassis parts that fit together like LEGOs.

- Custom Creations: From unique furniture frames to components for art installations, the possibilities are virtually endless. If you can dream it in metal tubing, a laser tube cutter in KC can probably make it. I wouldn't be surprised if someone's commissioned a laser-cut, stainless steel BBQ smoker that looks like a spaceship!

The efficiency is off the charts. What used to take hours, multiple machines, and several human operators can now be done in minutes by one incredible machine. This means faster production times and reduced waste – both good for business and the environment.

Beyond the Glare: The Human Element

Now, don't go thinking it's all just robots doing cool stuff. Behind every one of these sophisticated machines are highly skilled individuals. Engineers who design the parts, programmers who translate those designs into laser commands, and technicians who meticulously operate and maintain the equipment. It’s a testament to human ingenuity collaborating with cutting-edge technology.

So, the next time you're strolling through Kansas City, munching on some burnt ends, or tapping your foot to a jazz beat, take a moment. Somewhere nearby, a powerful laser is silently, precisely, and incredibly efficiently slicing through metal tubes, building the future, one perfect cut at a time. It’s a side of KC that’s less about sauce and more about science fiction become reality. And that, my friends, is pretty darn amazing.