Picture this: you’ve got a fantastic idea for a new DIY project, maybe a sleek aluminum frame for a garden bench, or perhaps patching up a beloved aluminum canoe that’s seen better days. You're eager to get started, your trusty flux core welder is humming, ready to join pieces of metal together with satisfying sparks and a shower of molten magic. But then, you hit a snag. The material in front of you isn't good old steel; it's shiny, lightweight aluminum. A thought bubbles up: "Can my flux core welder handle this?"

The Great Aluminum Flux Core Mystery

It’s a question that has sparked many lively debates in workshops and online forums, often with a mix of knowing smiles and outright head-shaking. For many, the very idea of using a flux core welder on aluminum feels a bit like trying to fit a square peg into a round hole. Or perhaps, attempting to toast a marshmallow with a flamethrower. You could, theoretically, but the results might be… less than ideal, and potentially quite messy.

“Trying to flux core weld aluminum is like asking a fish to climb a tree. It’s just not built for it, bless its little heart.” – A grizzled, experienced welder, probably after seeing one too many failed attempts.

The truth, for most everyday hobbyists and DIY enthusiasts, is a resounding "not really, and you probably shouldn't bother." While it's a fascinating thought experiment, and the human spirit of experimentation knows no bounds, the practical reality of getting a good, strong, clean weld on aluminum with a standard flux core welder is a journey often paved with frustration, melted metal, and maybe a few choice words.

The Adventure of Trying Anyway!

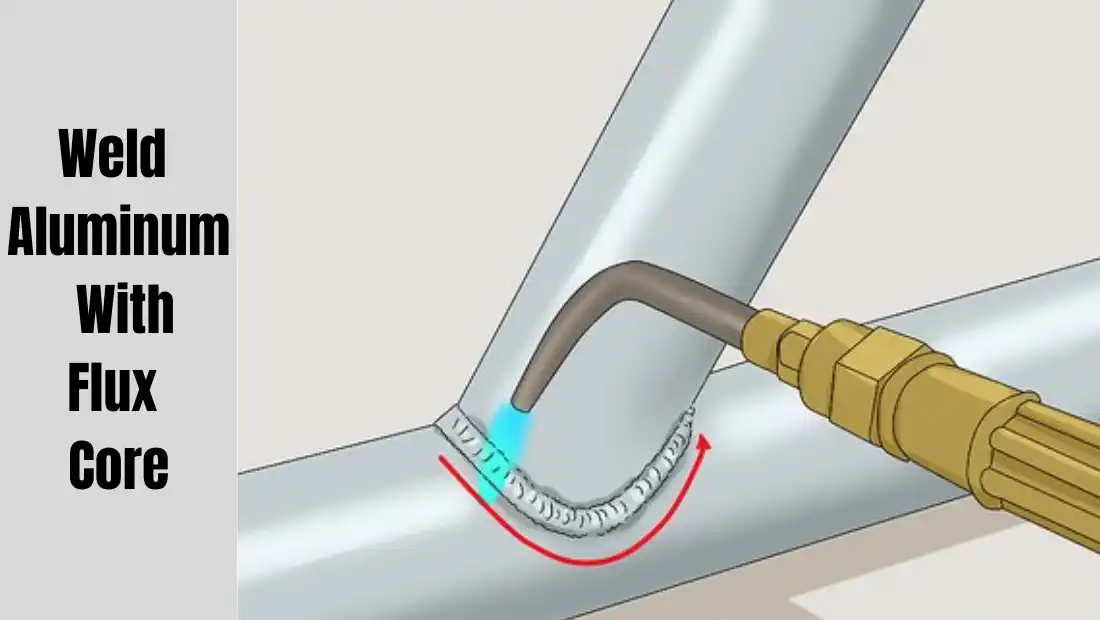

But let's be honest, who among us hasn't been tempted to push the boundaries? To look at a tool and wonder, "What else can it do?" There’s a certain charming audacity to someone meticulously cleaning their aluminum, setting up their flux core machine, and going for it. They might be picturing a seamless join, a proud moment of ingenuity. What they often get instead is a sputtering mess, a dark, sooty weld full of porosity (tiny little holes, like Swiss cheese), and a piece of aluminum that looks more like it's been attacked by a very angry badger than professionally joined.

The aluminum, bless its reactive heart, just doesn’t play nice with the typical characteristics of flux core wire. It oxidizes almost instantly, it conducts heat away like a tiny metal speed demon, and it generally prefers a much gentler, cleaner, and more controlled approach than what flux core welding typically offers. Imagine trying to sculpt a delicate rose out of butter with a sledgehammer; that's kind of the vibe.

So, What's the Real Deal for Aluminum?

Fear not, fellow creators! This isn’t to say that aluminum welding is impossible. Far from it! It just requires the right tools for the job, tools that were specifically designed to charm aluminum into submission. We're talking about the champions of aluminum welding: MIG welding with a spool gun and pure argon shielding gas, or the even more precise and beautiful art of TIG welding.

These methods offer the clean environment, the precise heat control, and the right filler materials that aluminum demands. They’re like the specialized surgeon to the flux core’s general practitioner. Both are fantastic at what they do, but you wouldn’t ask your GP to perform open-heart surgery, right?

The Joy of Learning (and Not Melting Everything)

So, the next time you find yourself gazing at that shiny piece of aluminum, resisting the urge to fire up the old flux core welder, take a moment to appreciate the journey of learning. It’s okay to be curious, and it’s even okay to experiment (safely, of course!). But true wisdom in the world of welding often comes from knowing when to grab the right tool, or when to politely step back and ask someone with the right equipment for a little help.

There’s a unique joy in using the right process for the right material, watching a clean, strong weld form, knowing you’ve respected the material and chosen the path to success. Leave the fantastical, messy attempts at flux core welding aluminum to the urban legends and the occasional brave, but ultimately misguided, experimenter. Your aluminum projects, and your sanity, will thank you for it!