Ever looked at a broken metal part and thought, "Well, that's toast!"? Maybe it was a cracked engine casing, a snapped piece of a patio chair, or a wonky antique lamp. If that part was made of aluminum, especially cast aluminum, you might have felt a special kind of despair.

Aluminum is awesome, right? It's light, strong, and resists rust. But fixing it, especially welding it, has always felt like trying to patch a cloud. And cast aluminum? That's a whole different beast.

So, here's the big question that sparks endless debate in workshops and garages worldwide: Can cast aluminum actually be welded? Is it even possible to bring these broken, chunky pieces back to life?

The short, exciting answer is a resounding, "Yes, absolutely!" But it's not like welding two pieces of steel together. Oh no, this is where the real fun begins. Welding cast aluminum is a challenge, a puzzle, and a triumph all rolled into one.

It’s like trying to perfectly mend a treasured but fragile ceramic vase, but with sparks and molten metal. There's a certain magic to it, a skillful dance that only experienced hands can truly master.

Why Is Cast Aluminum So Special (and Tricky)?

Think of regular aluminum as a smooth, uniform sheet of paper. It’s consistent. Now, imagine cast aluminum as a rough, chunky oatmeal cookie. It’s made by pouring molten metal into a mold, and sometimes, it ends up with tiny pockets, impurities, and a grainier texture.

These little imperfections are what make it so unique. They also make it a bit of a diva when it comes to welding. It's like trying to glue together a sponge that's already soaked up a bunch of unknown stuff!

One of the biggest hurdles is that cast aluminum loves to absorb everything. Dirt, oil, grease, even moisture – it all gets trapped within those tiny pores and grains. When you try to heat it up for welding, these contaminants cause all sorts of trouble, making the weld weak and ugly.

"Welding cast aluminum isn't just a repair; it's an archaeological dig to clean up the past."

Another quirky trait of aluminum is its invisible shield. Aluminum forms a super tough oxide layer on its surface, almost instantly. This layer has a much higher melting point than the aluminum itself. So, you're trying to melt something that's hiding under a stronger, higher-melting-point skin!

The Thrill of the Challenge

This is precisely why welding cast aluminum is so engaging. It’s not a straightforward task. It demands patience, meticulous preparation, and a deep understanding of how this peculiar metal behaves.

It's the kind of project that separates the casual hobbyist from the truly dedicated craftsman. Every successful weld on a tricky piece of cast aluminum feels like winning a small, personal gold medal.

The preparation alone can be an adventure. Grinding, cleaning, degreasing – sometimes even baking the part to cook out impurities. It’s a bit like a chef preparing a very delicate ingredient; every step matters.

The Tools of the Trade: The Welder's Superpowers

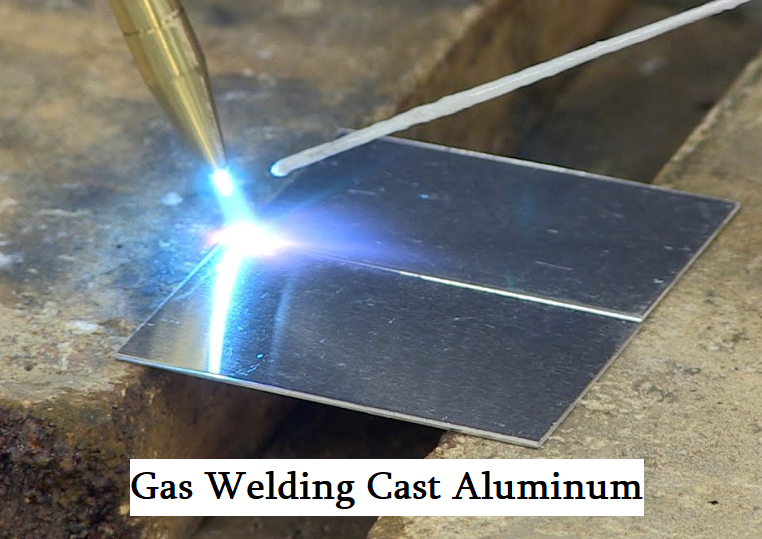

So, how do you conquer this challenging material? The hero of this story is often a welding process called TIG welding, or Gas Tungsten Arc Welding (GTAW).

Imagine a welder using a super-fine, precise flamethrower. That's TIG, in a very simplified nutshell. It allows for incredible control over the heat and the molten puddle. It’s like performing delicate surgery with a controlled bolt of lightning.

The TIG welder uses a non-consumable tungsten electrode and a separate filler rod. This setup lets the welder introduce new, clean aluminum into the weld, helping to override the old, contaminated stuff.

There's also the magic of alternating current (AC) for TIG welding aluminum. AC helps to break up that stubborn oxide layer, almost like a tiny scrubbing action, allowing the actual aluminum to melt cleanly.

Watching a skilled TIG welder work on cast aluminum is mesmerizing. The focused arc, the controlled addition of the filler rod, the way the metal slowly joins, bead by beautiful bead. It’s a silent, intense ballet of light and heat.

The Art of the Weld

It's truly an art form. The welder has to feel the metal, understand its subtle cues, and adjust their technique on the fly. Too much heat, and the thin metal can simply collapse into a puddle. Too little, and the weld won't fuse properly.

A steady hand, keen eyesight, and immense patience are crucial. It's not just about pushing buttons; it's about developing a unique connection with the material.

When a broken engine block, a vintage motorcycle part, or a cherished garden ornament is perfectly repaired, it's not just a fix. It's a resurrection. It’s a testament to human ingenuity and skill.

Why You Should Be Curious About It

Beyond the technical wizardry, there's a deep satisfaction in being able to mend something that others would simply discard. It's a sustainable act, a defiance against planned obsolescence.

Think about all the things made of cast aluminum around you. Car parts, boat components, outdoor furniture, kitchen equipment. When something breaks, being able to weld it back together extends its life and saves resources.

It’s also incredibly cool to witness. If you ever get a chance to see a welder tackle a tricky cast aluminum repair, take it! You’ll gain a new appreciation for the precision, the heat, and the almost magical transformation happening right before your eyes.

It inspires a sense of possibility. What else can be fixed? What other challenges can be overcome with the right knowledge and tools?

"The whisper of the TIG torch bringing cast aluminum back to life is music to any fabricator's ears."

Many welders share their incredible projects online, showcasing jaw-dropping repairs. They often document the entire process, from the gritty prep work to the final, gleaming weld. It's fascinating to follow along!

Inspiring the Inner Fixer

Perhaps it even sparks something in you. The desire to learn a craft, to work with your hands, to solve tangible problems. Welding, especially with tricky materials like cast aluminum, offers endless opportunities for learning and mastery.

So, the next time you see a broken cast aluminum piece, don't automatically think "junk." Think "challenge." Think "opportunity." Think "welder's playground."

The answer is a resounding yes: cast aluminum can be welded. And it’s a process filled with challenge, skill, and immense satisfaction. It’s a testament to the marvels of modern craftsmanship and the enduring human desire to fix, create, and master.

It transforms what seems impossible into an exciting reality. It's definitely something worth admiring, celebrating, and perhaps even inspiring you to explore further!