Have you ever heard of the term "bootstrapping"? It's often used in business, meaning to build something from absolutely nothing, using only what you have. Well, in the world of 3D printing, there's a surprisingly similar concept: building a 3D printer… with another 3D printer! Sounds a bit like science fiction, right? But it's a fascinating and surprisingly accessible concept that opens up a whole new world of possibilities.

Why would you even want to do this? Firstly, it's just plain cool. The idea of a machine creating its own offspring is something straight out of a sci-fi novel. But beyond the novelty, it’s a powerful demonstration of the potential of additive manufacturing. Imagine a future where remote communities can manufacture their own tools and equipment, relying only on a seed 3D printer and readily available filament.

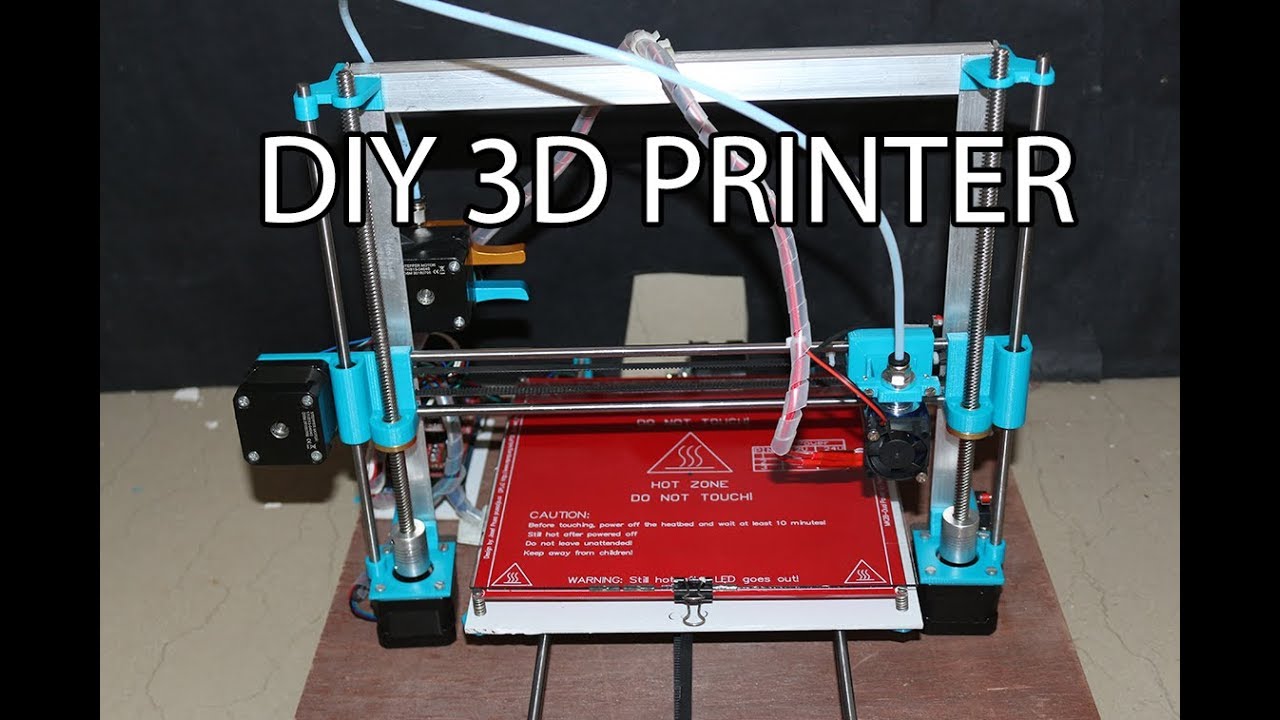

The core purpose is to leverage the self-replicating capabilities (to a degree) of 3D printing. You start with a functional 3D printer. Many of the structural components, brackets, and smaller pieces of another printer can then be 3D printed using the first. Of course, you'll still need to source the electronic components like the control board, motors, hot end, and power supply – these can't be printed (yet!). The benefit here is significantly reducing the overall cost of building a second printer, especially if you already have one readily available and can print multiple sets of parts.

This also opens doors for customization. Want a slightly larger build volume? A different frame design? When you're printing the parts yourself, you have a lot more control over the final product. You can modify existing open-source designs or even create your own, tailoring the printer to your specific needs.

In education, this concept is invaluable. It provides a hands-on lesson in mechanical engineering, electronics, and computer-aided design (CAD). Students can learn about the inner workings of a 3D printer by literally building one from the ground up. They can also experiment with different materials and designs, gaining a deeper understanding of the 3D printing process.

Beyond the classroom, imagine using a 3D-printed 3D printer to create customized tools for your home workshop, repair broken household items, or even prototype new inventions. The possibilities are truly endless. Consider a scenario where a maker space has a small farm of 3D printers, all capable of replicating each other; a single point of failure would no longer be a major catastrophe.

So, how can you explore this fascinating world? Start small. Familiarize yourself with open-source 3D printer designs like the RepRap project – these are specifically designed to be self-replicating. Download the CAD files and examine the parts. Then, consider printing a few of the simpler components to get a feel for the process. There are countless online communities and tutorials that can guide you through the entire process. The biggest hurdle will be the electronics components and the initial cost, which require more careful planning. But the long-term savings in both cost and learning are absolutely worth the effort.

Don't be afraid to experiment and learn from your mistakes. Building a 3D printer with a 3D printer is a challenging but rewarding project that will deepen your understanding of this transformative technology and unlock your creative potential. It's a journey of learning, innovation, and ultimately, empowerment.