Ever gazed up at a towering skyscraper, driven across a magnificent bridge, or admired the sleek design of a modern car? What do all these marvels of engineering have in common? They’re held together by welds! And ensuring those welds are as strong, safe, and reliable as humanly possible is the noble pursuit of the Certified Welding Inspector (CWI). While "study material" might sound like a dry topic, preparing for the AWS CWI exam is actually a fascinating journey into the very backbone of our modern world. It’s for those who find satisfaction in precision, those who understand that tiny details can have massive impacts, and those who want to be the guardians of structural integrity.

The benefits of diving into CWI study material extend far beyond just passing an exam. This knowledge serves a profound purpose in everyday life: it ensures our safety! Imagine a world where welds fail on pipelines carrying essential resources, or on critical components of a rollercoaster. It's a terrifying thought. A CWI’s expertise prevents these catastrophes, guaranteeing the quality and safety of everything from our homes to our hospitals. It's about building trust, preventing costly repairs, and ultimately, saving lives. For individuals, it's a pathway to a highly respected and in-demand career, offering excellent opportunities for professional growth and a sense of contributing to something truly fundamental.

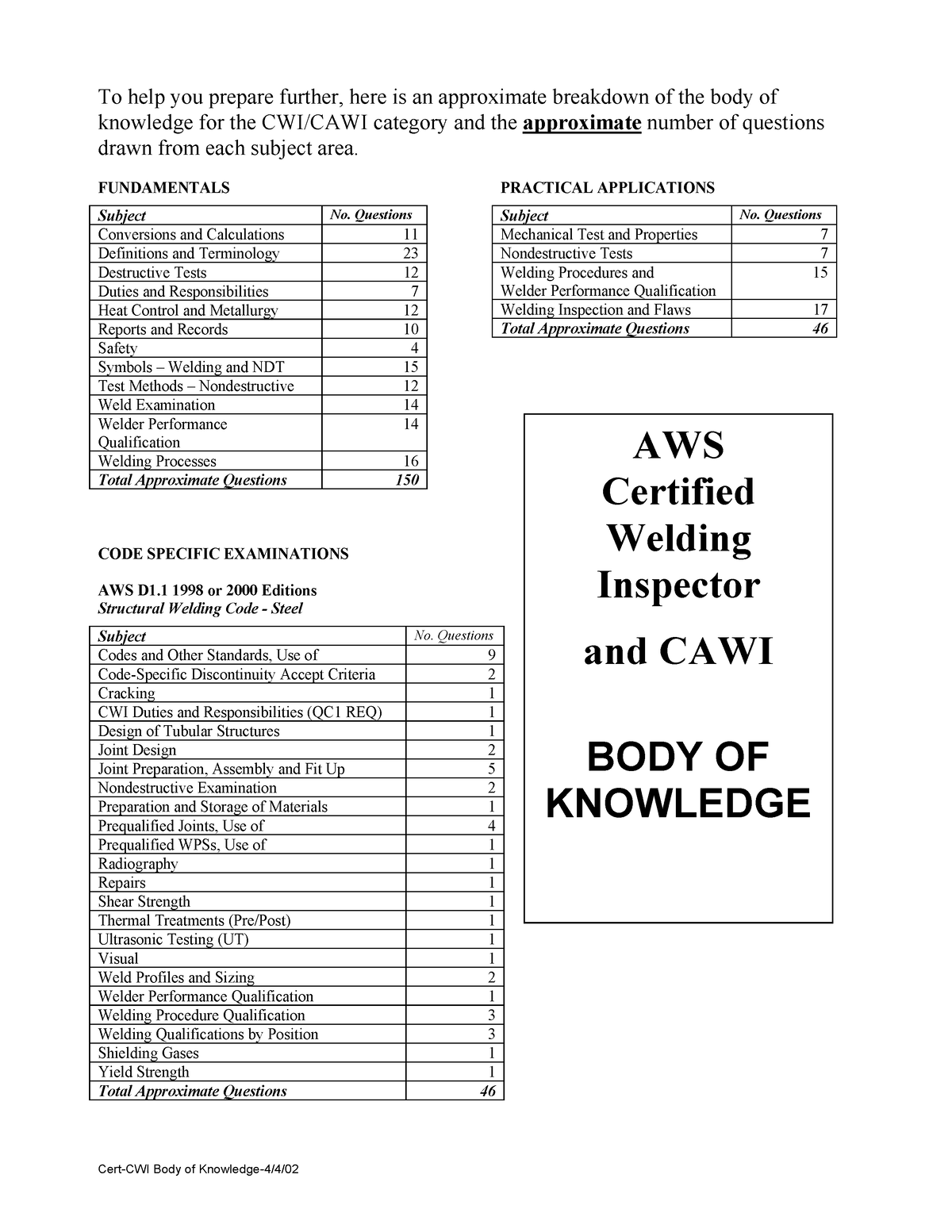

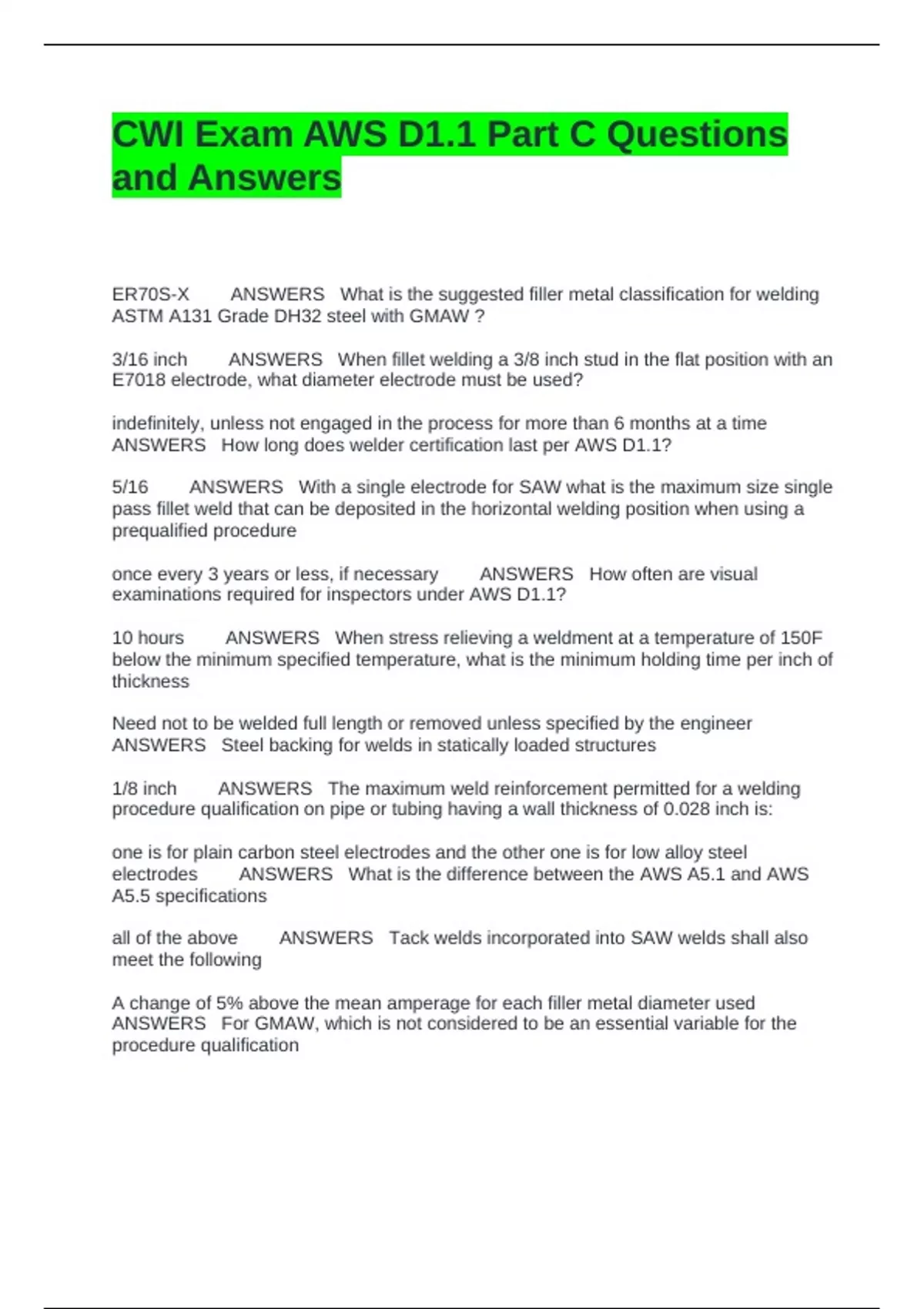

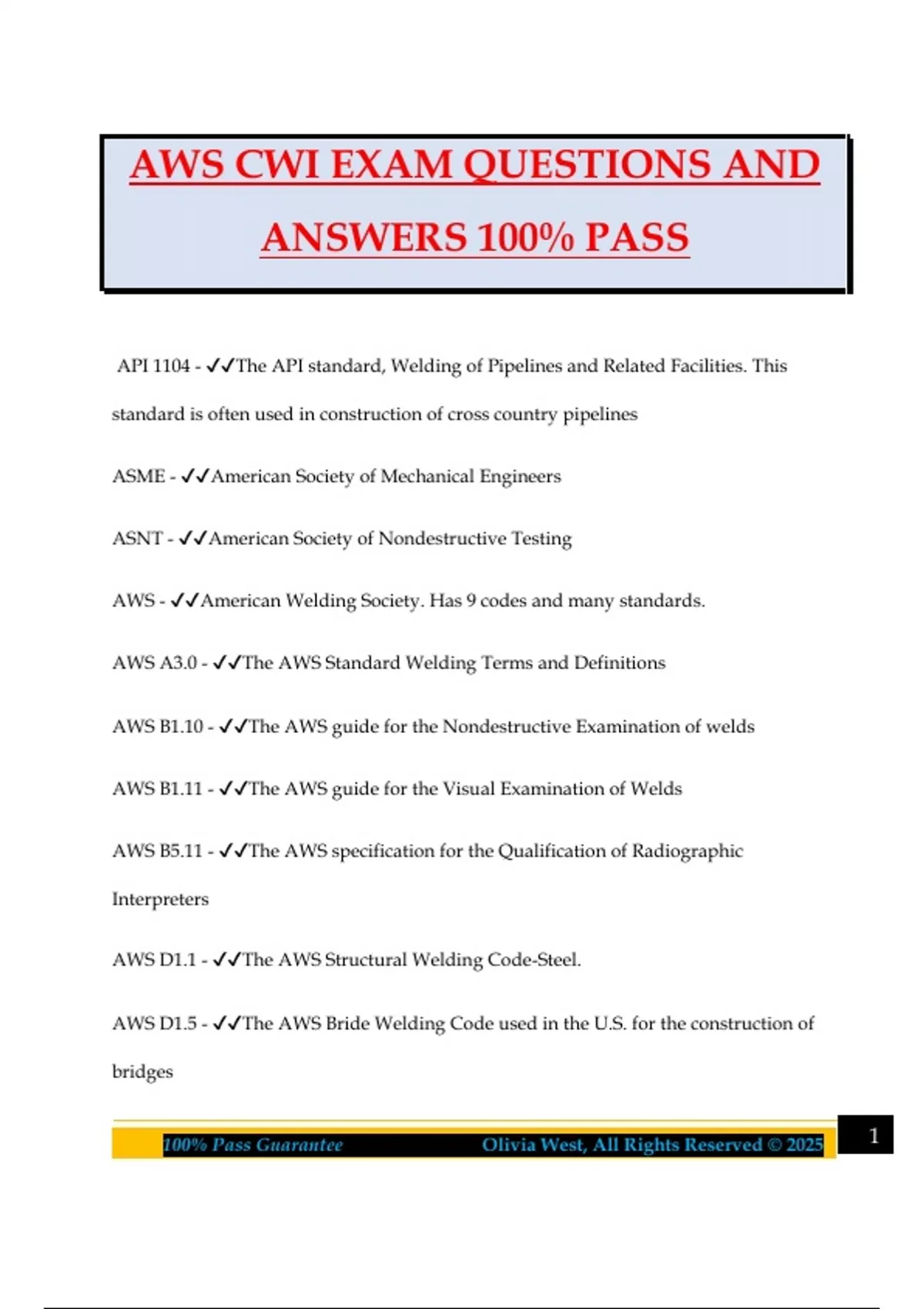

So, where is this knowledge applied? Practically everywhere! Look around you: the chair you’re sitting on, the bicycle you ride, the airplane that takes you on vacation, the massive ships that transport goods across oceans, and even the intricate machinery manufacturing our favorite products – all feature welds. CWIs are the unsung heroes on construction sites ensuring skyscraper beams are perfectly joined, in fabrication shops verifying custom parts, and in oil fields inspecting crucial infrastructure. They interpret complex codes like AWS D1.1, identify discontinuities, and ensure adherence to rigorous standards. It's a role that demands a sharp eye, a keen mind, and a deep understanding of metal properties and welding processes.

Ready to embark on this intellectual adventure and make your CWI study material truly engaging? Here are some practical tips. Firstly, don't just memorize; understand the "why" behind every concept. Why does preheat matter? Why is a certain defect critical? Connecting theory to real-world consequences makes the information stick. Secondly, visualize! When you read about a welding process or a type of discontinuity, try to picture it in your mind or, better yet, find videos and diagrams. Consider joining a study group; discussing challenging topics with peers can clarify doubts and offer new perspectives, making the learning process more collaborative and enjoyable. Most importantly, practice, practice, practice! Work through sample questions and familiarise yourself with reference materials. Treat the study journey not as a chore, but as an opportunity to become an expert in the very foundations of our built world. Embrace the challenge, and you'll find the satisfaction of mastering the CWI material immensely rewarding.