Ever tried building something with LEGOs and realized you were *one* brick short of absolute genius? We've all been there. Now, imagine that feeling, but instead of tiny plastic bricks, you're dealing with...well, anything! That's where 3D printing, or as the cool kids call it, additive manufacturing, comes in. Think of it as a super-powered LEGO builder for adults (and kids, let's be honest).

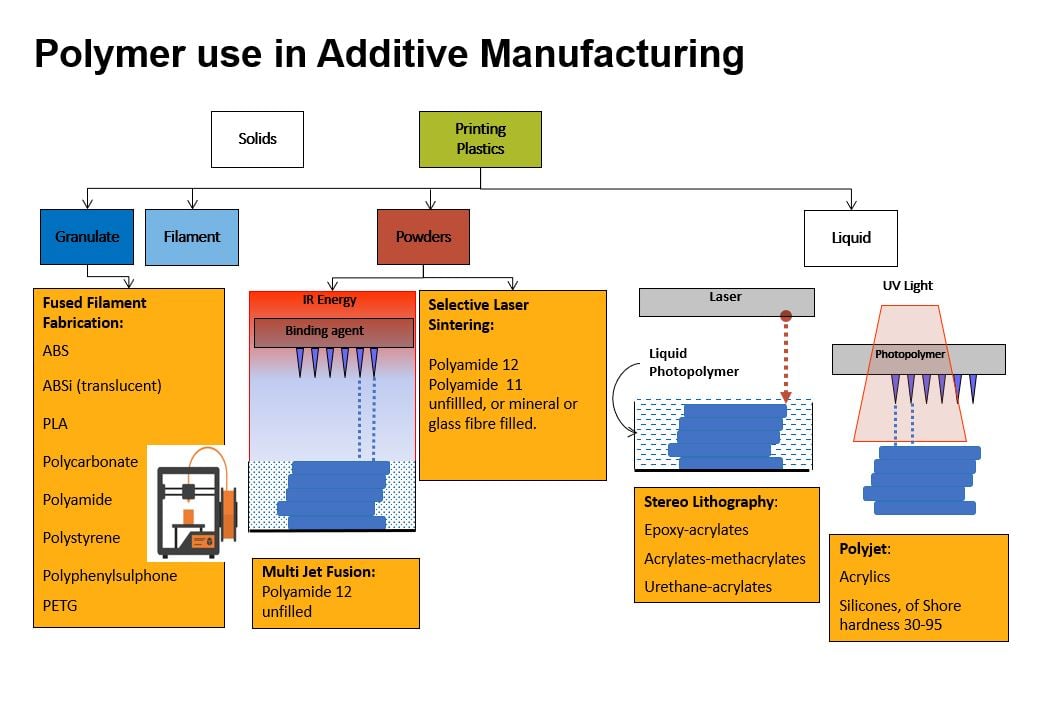

But instead of snapping blocks together, it *builds* stuff layer by layer, like a magical cake decorator icing a masterpiece. Only instead of icing, it uses materials like plastic, metal, ceramics, or even… wait for it… chocolate! (Okay, maybe not for serious manufacturing, but the *possibility* is there!).

Prototyping: Testing the Waters (Without Drowning)

Let's say you've invented the next big thing: the self-stirring coffee mug that *also* plays your favorite tunes. Genius, right? But before you sink your life savings into mass-producing millions, you probably want to, you know, *test* it. Enter 3D printing!

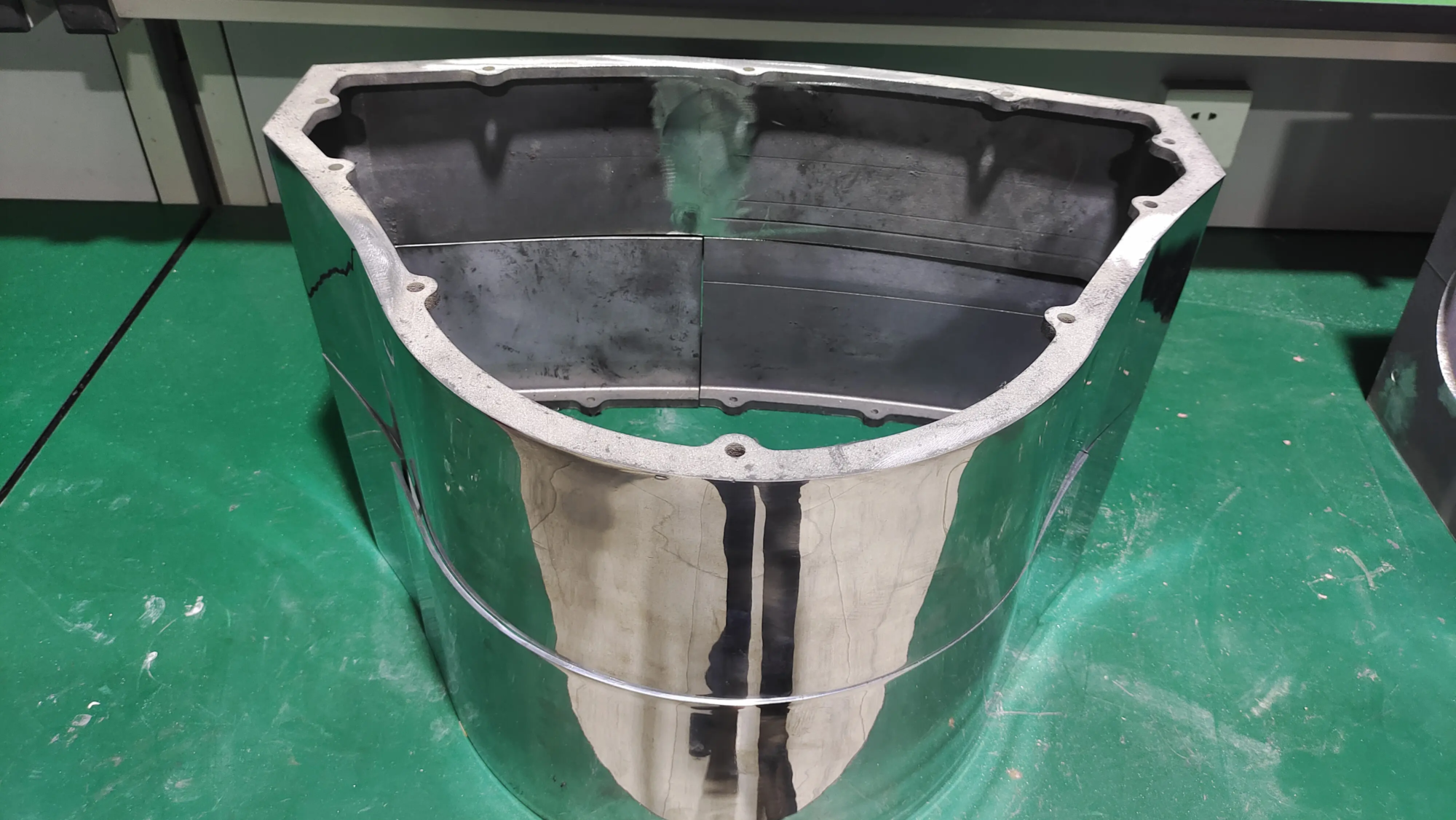

Prototyping with 3D printing is like sketching a design before committing to a full-blown oil painting. You can quickly create a physical model, hold it in your hands, pour coffee into it (carefully!), and see if your revolutionary invention actually… well, *works*. Does the music blast your eardrums? Is the stirring mechanism actually making a coffee volcano? 3D printing helps you iron out those kinks *before* they cost you a fortune. It's like having a "redo" button in real life!

Imagine trying to explain a complex invention to investors. A fancy PowerPoint is nice, but handing them a tangible, 3D-printed prototype? That’s a mic-drop moment right there. It’s way more convincing than just saying, "Trust me, it's gonna be awesome!" Plus, you can iterate rapidly. Change a design element? Print a new version *tomorrow*. Try doing *that* with traditional manufacturing! You’d be waiting months, and your investors would probably forget your name.

Manufacturing: Not Just for Space Rockets Anymore

So, you've perfected your self-stirring, music-playing mug. Now what? Time to unleash it upon the world! 3D printing isn't just for prototypes anymore. It’s creeping its way into actual, *real* manufacturing.

Why is this a big deal? Think about custom-made medical implants perfectly shaped to fit *your* body. Or spare parts for vintage cars that haven't been manufactured in decades. Or even personalized phone cases with your face on them! (Okay, maybe that's going too far, but you get the idea!).

Traditional manufacturing often requires massive production runs to be cost-effective. 3D printing allows for *smaller* batches and even customized products, making it ideal for niche markets and specialized applications. It's like having a personal factory at your fingertips! Need 50 purple widgets with a special hole in the middle? No problem! Need one *gold-plated* widget shaped like a unicorn? Probably still no problem (assuming you have the right printer and a serious unicorn obsession).

Of course, it’s not all sunshine and roses. 3D printing can be slower and more expensive than traditional manufacturing for very *large* production volumes. But as technology advances, these limitations are shrinking faster than you can say "rapid prototyping."

The future of manufacturing? It's looking pretty 3D. From personalized medicine to faster product development, additive manufacturing is changing the way we design, create, and consume. So next time you see a perfectly formed gadget, remember there’s a good chance it started as a digital dream, built layer by layer, one magical drop of material at a time. And who knows, maybe *your* next world-changing invention will be brought to life by the power of 3D printing. Just try not to make it a coffee volcano, okay?