Ever peeked at a welding machine? It looks like a spaceship control panel, all knobs and numbers. Intimidating, right? Wrong! It’s actually a big, friendly metal-melting monster, and figuring out its secret language – like for 045 flux core wire settings – is half the fun!

Today, we’re diving into the delightful world of 045 flux core wire. It sounds super technical, but trust me, it’s just a fancy way of saying "chunky, self-shielding, metal-joining magic." And getting those settings just right? That's where the real magic happens.

Why 045 Flux Core? It's a Beast!

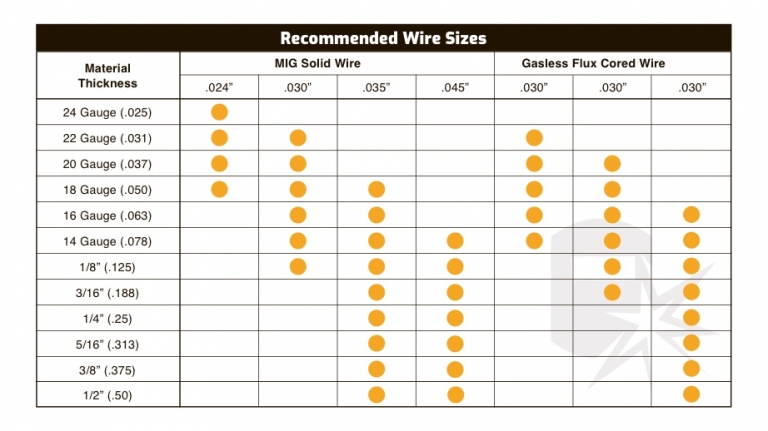

First off, why 045? That number refers to the wire's diameter in inches. So, 0.045 inches. It's a pretty thick wire! Think of it like the difference between a delicate spaghetti noodle and a hearty rigatoni. This thickness means it’s fantastic for welding thicker materials. We’re talking about those projects where strength is key, and a little extra oomph is needed. Bridges, heavy machinery, stuff that needs to hold together like a grumpy badger on a biscuit.

And flux core? That’s the superhero part. This wire has a hollow center filled with a special powder, the "flux." When it burns, it creates its own protective gas shield. No need for a separate gas tank! It’s like a tiny, self-contained chemistry lab exploding in your weld puddle. How cool is that? It means you can weld outside on a windy day, something traditional MIG welding struggles with.

The Dynamic Duo: Voltage and Wire Speed

Now, for the juicy bits: the settings! There are two main characters in this play: voltage and wire feed speed (WFS).

Think of it like this:

- Voltage (V) is your "heat" or "arc length." Too low, and your weld will look like cold, lumpy dog doo. Too high, and you'll blow holes faster than a gopher on espresso.

- Wire Feed Speed (WFS) is how fast the wire squirts out of your gun. Too slow, and the arc will stutter and sputter, making angry noises. Too fast, and the wire will just jam into the metal, making a sticky mess.

It's a delicate dance! A rhythmic tango between electricity and molten metal.

Finding Your Sweet Spot: Starting Points for 045

So, where do you even begin with this chunky 045 wire? Every machine is a little different, like every chef has their own secret spice blend. But here are some great starting points for flux core 045 on common 120V or 240V machines:

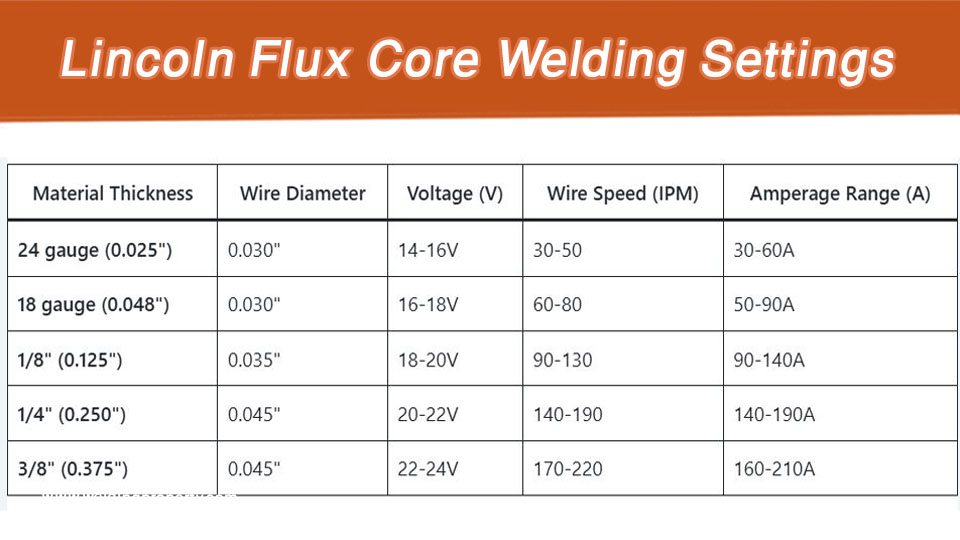

For thicker materials (say, 1/4 inch to 3/8 inch steel), you'll often be looking in these neighborhoods:

- Voltage: Around 19V to 22V. Yeah, it's pretty hot! This wire loves heat.

- Wire Feed Speed: Somewhere between 180 to 250 Inches Per Minute (IPM). That's pretty zippy!

Remember, these are just a starting guess. Your machine might have a handy chart right inside its door – always check that first! It's like finding a treasure map to welding bliss.

The Sound of Success (and Failure!)

How do you know you're getting it right? Use your senses!

- The Sound: A perfect flux core weld sounds like crispy bacon frying, or a steady, aggressive sizzle. If it sounds like a machine gun or a sputtering wet cat, something's off!

- The Sight: Watch your weld puddle. It should be smooth, consistent, and wet, spreading evenly. If it's lumpy, cold, or full of holes, time for adjustments!

When your settings are wrong, it’s actually quite funny to observe. Too little voltage and too much WFS? You get "cold lap" – where the wire just piles up without really fusing. It looks like a worm crawling across the metal. Gross! Too much voltage and too little WFS? You'll be splattering molten metal everywhere like a rogue sprinkler. And those holes? Yeah, those are called "burn-throughs," and they're less fun to fix.

Stick-Out: The Forgotten Hero

There's another unsung hero: wire stick-out. That's how much wire pokes out from the end of your welding gun's nozzle before you strike an arc. For 045 flux core, you generally want a longer stick-out than with solid wire. Think around 3/4 inch to 1 inch. This extra length helps preheat the wire and burn off some of that flux, making for a smoother, hotter arc. It's a small detail, but it makes a big difference!

Flux Core's Quirky Charm: It's Not Always Pretty!

One last quirky fact about flux core: it's not known for its beauty contests. When you're done, you'll have a layer of slag – a glassy, crusty residue – covering your weld. This is normal! It's the byproduct of that self-shielding flux. You'll need to chip it off and brush your weld clean. It's a bit like unwrapping a present; you have to get through the packaging to see the shiny, strong weld underneath!

So, next time you see those knobs, don't just stare. Give them a twist! Experiment! Listen to the bacon sizzle! Adjusting 045 flux core settings is less about perfect numbers and more about finding that harmonious balance. It’s a rewarding puzzle, and when you nail it, you're not just welding metal, you're creating something strong and durable. And that, my friend, is truly awesome.