Alright, picture this. You’re at a café, right? Latte in hand, maybe a questionable pastry selection. And the topic comes up: electrical wiring. Suddenly, everyone’s an expert, confidently throwing around terms like "amperage" and "gauge" like they’re ordering complicated coffee drinks. But let’s cut through the caffeine-fueled chaos and get down to brass tacks, specifically about the size of wire you need for a 100 amp panel. Because trust me, messing this up is way worse than a burnt croissant.

The 100 Amp Quandary: Not as Scary as It Sounds

So, you’ve got yourself a 100 amp electrical panel. Maybe you're upgrading, maybe you're building a she-shed (complete with a disco ball, I hope!), or maybe you just like saying the words "100 amps" to sound important. Whatever the reason, you need to connect it to the main power source. And that means wires. Big wires. The question is, how big?

Think of it like this: Amps are like water flowing through a pipe. The higher the amps, the more water. The wire is the pipe. If the pipe is too small, you get a flood! (Okay, maybe not a literal flood, but definitely overheated wires and potentially a fire hazard. Not fun.)

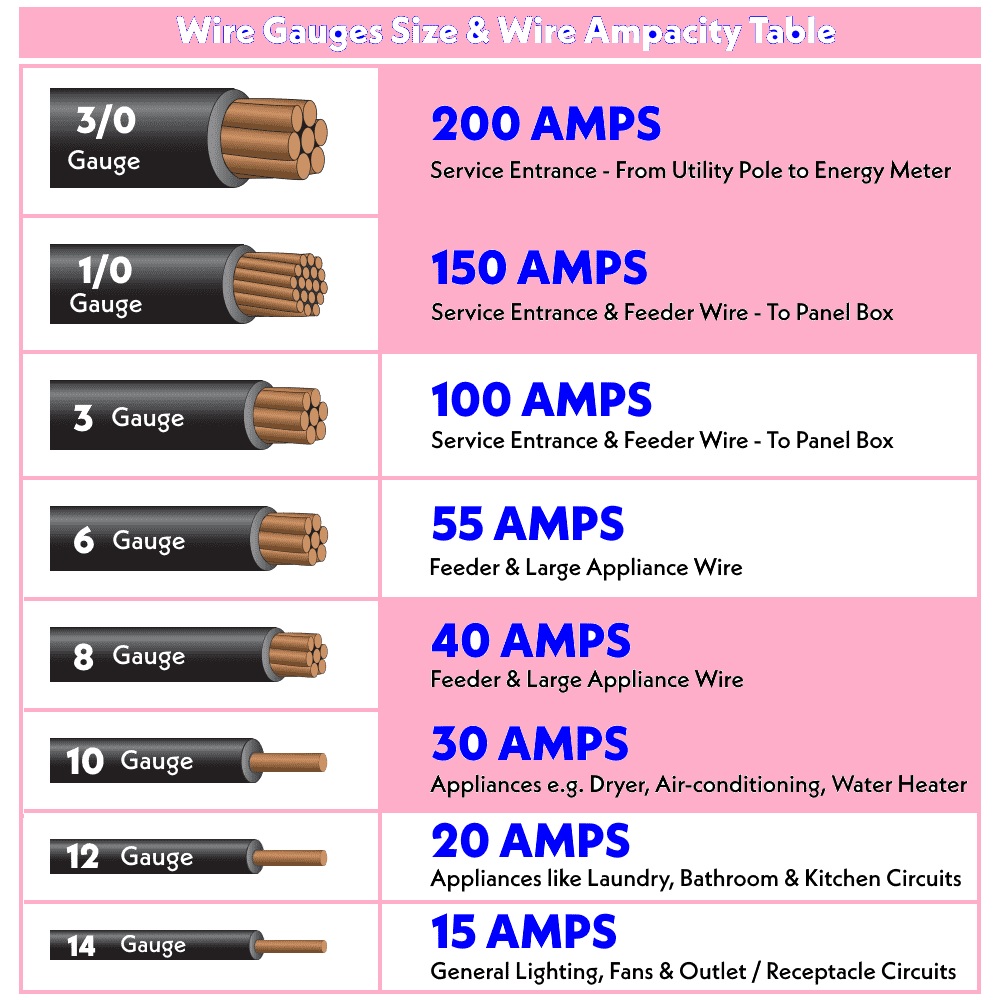

Therefore, the standard recommendation for a 100 amp service is to use a wire size of at least #4 AWG copper wire, or #2 AWG aluminum wire. But hold your horses, there's a "but" coming.

The "But" and Other Complications (Like Your Uncle Larry)

Ah, the "but." It's always there, isn't it? Like that one uncle who gives unsolicited investment advice at Thanksgiving. In the world of electrical wiring, the "but" comes in the form of factors that can influence the wire size you *actually* need.

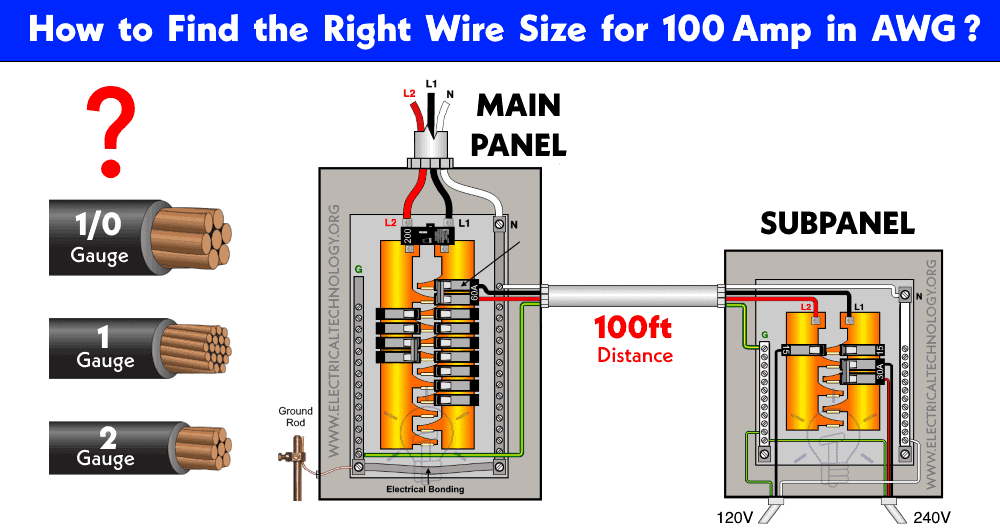

- Distance: The longer the distance between the main power source and your 100 amp panel, the bigger the wire you need. This is because of something called "voltage drop." Imagine shouting at someone across a football field. The further away they are, the harder it is for them to hear you clearly. Voltage drop is similar – the further the electricity has to travel, the weaker it gets. Bigger wires help counteract this. So, if your panel is located a million miles away (exaggerating, slightly), you might need to up the wire size.

- Material: Copper is the gold standard (or, well, the copper standard) for electrical wiring. It's a great conductor. Aluminum is cheaper, but it's not as good a conductor, so you need a thicker aluminum wire to carry the same amount of current as a copper wire. We mentioned this earlier, so pay attention!

- Local Codes: This is a big one. Your local electrical codes are the *law*. They supersede anything I tell you here. Seriously. They might have specific requirements for wire size, conduit type, and grounding. Ignoring them is like painting your house neon pink in a historical district – it's just asking for trouble.

Pro-tip: Always consult your local electrical codes and a qualified electrician! I can tell you what generally works, but they know the specifics for your area and can ensure everything is safe and up to code. Think of them as your electrical Yoda.

Copper vs. Aluminum: The Great Wire Debate

Let's briefly delve into the age-old debate: copper versus aluminum. Copper is like that reliable friend who always shows up on time and never lets you down. Aluminum is like that friend who's always trying to get you into cryptocurrency (risky, but potentially rewarding?).

Copper is more conductive, more durable, and generally considered the better choice. But it's also more expensive. Aluminum is cheaper and lighter, which can be a benefit for long runs. However, it's more prone to corrosion and requires special connectors to prevent issues. If you go aluminum, be sure your connections are properly torqued and use an anti-oxidant paste to prevent corrosion.

For a 100 amp service, copper is often the preferred choice, especially for shorter runs. But if you're on a tight budget and have a long distance to cover, aluminum might be a viable option, *provided* it's installed correctly and meets code requirements.

Grounding: Don't Forget the Earth Connection!

Grounding is like the safety net of your electrical system. It provides a path for fault current to flow back to the source, tripping a breaker and preventing electrocution. It's extremely important.

The size of the grounding wire depends on the size of the service conductors. For a 100 amp service, a #8 AWG copper grounding wire is generally required. Again, check your local codes!

Final Thoughts (and a Warning)

Choosing the right wire size for a 100 amp panel is crucial for safety and performance. Don't skimp, don't guess, and for the love of all that is electrically sound, don't try to save a few bucks by using undersized wire. It's not worth the risk of fire, electrocution, or having to explain to your insurance company why your she-shed went up in flames.

Electricity is dangerous. If you're not comfortable working with it, hire a qualified electrician. They'll know exactly what wire size to use, how to install it safely, and how to get it inspected. It's an investment in your safety and peace of mind. Plus, you'll have someone to blame if the disco ball malfunctions (just kidding… mostly).

So, there you have it! The (somewhat) definitive guide to wire sizes for a 100 amp panel. Now go forth, be electrically responsible, and may your circuits never overload!