There's something deeply satisfying about welding. Maybe it's the controlled power of electricity, the creative potential to shape metal, or the sheer practicality of fixing something yourself. Whatever the reason, welding is a skill enjoyed by hobbyists and professionals alike, a way to bring ideas to life and keep the world running smoothly.

Welding is more than just joining metal; it's about connecting. It's the backbone of countless industries, from constructing skyscrapers and bridges to fabricating cars and airplanes. Think about it: almost everything around you, from the chair you're sitting on to the appliances in your kitchen, likely involved welding at some stage of its creation. It's a fundamental process in manufacturing, repair, and even art.

Beyond large-scale applications, welding empowers individuals to tackle everyday repairs and projects. A broken gate hinge? Weld it! A custom metal art piece for your garden? Weld it! Building a sturdy frame for your next DIY project? You guessed it – weld it! The possibilities are truly endless, making welding a valuable skill for anyone looking to be self-sufficient and creative.

Now, let's get down to brass tacks: choosing the right size welding leads. This is crucial for safe and effective welding. Think of your welding leads as the arteries carrying the lifeblood (electricity) to your welding machine. Too small, and the flow is restricted, leading to voltage drop, reduced welding performance, and even potential damage to your equipment. Too big, and you're wasting money on unnecessary copper.

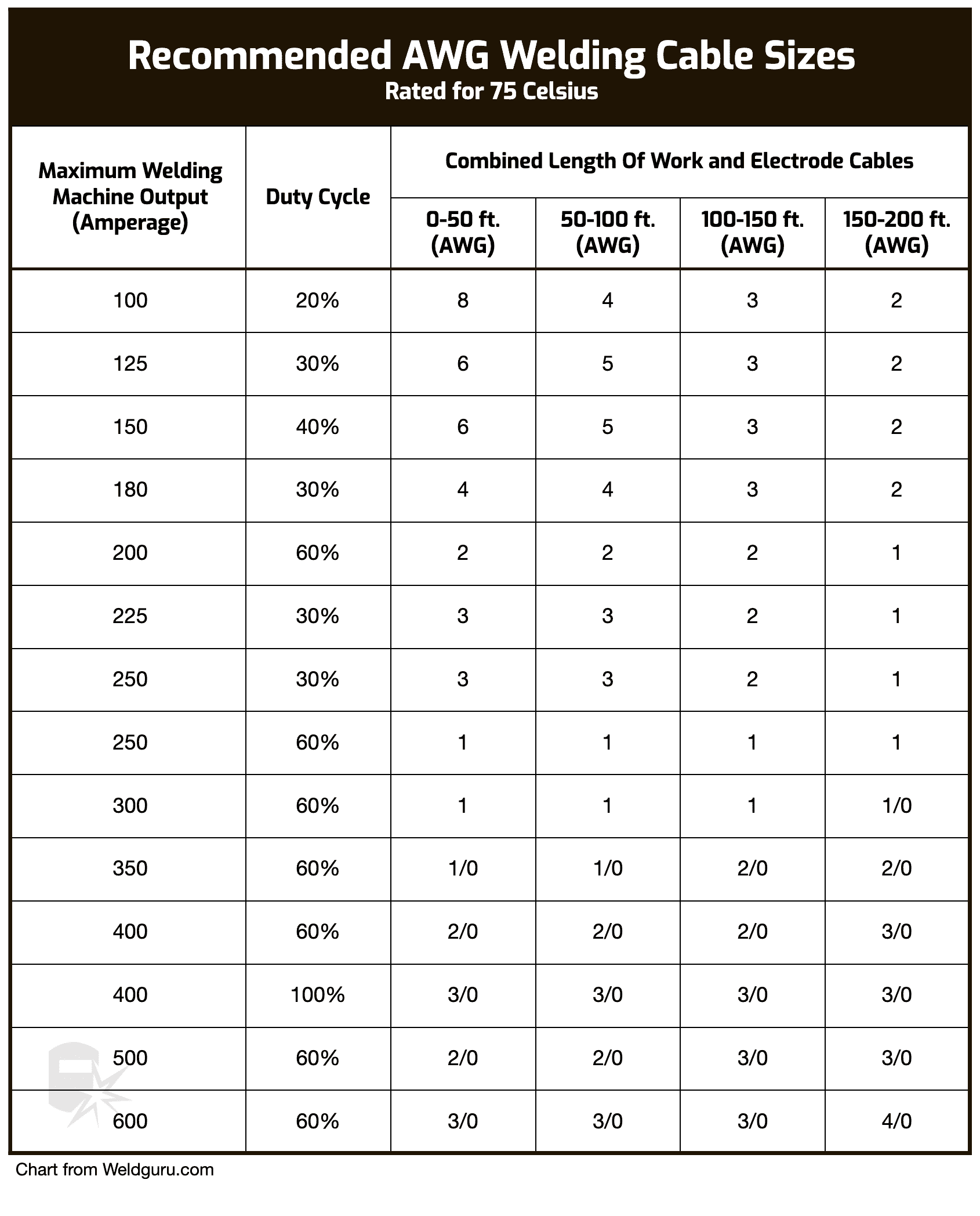

So, how do you figure out what size you need? Several factors come into play. Amperage is the most important. The higher the amperage you'll be welding at, the thicker your leads need to be. Then there's length. The longer the leads, the more resistance they have, so you'll need a thicker gauge for longer runs. Finally, consider the duty cycle of your welder. If you're welding continuously for extended periods, thicker leads will help prevent overheating.

Here's a practical tip: consult a welding lead size chart. These charts, readily available online and in welding supply stores, provide a guideline based on amperage, length, and duty cycle. Always err on the side of caution and choose a slightly larger gauge than recommended, especially if you plan on doing a lot of high-amperage welding. Remember, it's better to have too much capacity than not enough.

Another tip: invest in quality welding leads. Cheap leads might seem tempting, but they often use lower-grade copper and may not be properly insulated. This can lead to poor performance, overheating, and even safety hazards. High-quality leads are an investment in your safety and the longevity of your welding equipment.

Finally, always inspect your welding leads before each use. Look for any signs of damage, such as cuts, abrasions, or exposed wires. Replace damaged leads immediately to prevent electrical shock. By choosing the right size welding leads and taking proper care of them, you can enjoy safer, more efficient, and more fulfilling welding experiences for years to come. Now get out there and weld something amazing!