Alright, buckle up buttercup! We're diving headfirst into the wild and wonderful world of MIG welding wire sizes. Forget everything you thought you knew, because we're about to make this so easy, your grandma could weld a race car (okay, maybe not, but you get the idea!).

Choosing the right size wire can feel like deciphering ancient hieroglyphics. Fear not! This guide will have you picking the perfect wire like a pro in no time.

The Wire Size Lowdown

Think of MIG wire like Goldilocks and the Three Bears. Too small, and your weld will be weak and sad. Too big, and you'll be battling a wild, spattery mess. You want the just right size.

MIG wire sizes are measured in thousandths of an inch (like .030, .035, .045). These numbers might seem tiny, but they make a HUGE difference.

The smaller the number, the thinner the wire. Makes sense, right?

The Mighty .030 Wire

This little guy is the go-to for thinner metals. We're talking sheet metal projects, auto body repair, maybe even crafting delicate robot sculptures (if that's your thing!).

Imagine trying to weld two soda cans together with a giant, thick wire. Disaster! The .030 wire is gentle and precise.

It’s like using a fine-tipped pen instead of a Sharpie – control is key.

The Popular .035 Wire

The .035 wire is the workhorse of the MIG welding world. It’s like the Swiss Army knife of wire – versatile and reliable.

It’s perfect for general purpose welding, auto frames, and projects around the house. You can fix your lawnmower, build a barbecue pit, or even construct a metal dragon for your garden (again, if you're into that sort of thing!).

This size offers a great balance between penetration and ease of use.

The Beefy .045 Wire

Now we're talking serious metal! The .045 wire is for those thicker projects that demand some real muscle. Think heavy equipment repair, structural steel, and building metal cages for your pet rhinoceros (hypothetically speaking, of course!).

This wire lays down a lot of weld metal, fast. It’s like using a fire hose instead of a garden hose – powerful!

But remember, with great power comes great responsibility (and potentially more spatter to clean up!).

Matching Wire Size to Metal Thickness

The most important factor in choosing the right wire size is the thickness of the metal you're welding. It's all about finding that sweet spot where the wire melts evenly and penetrates the metal without blowing holes through it.

Think of it like cooking a steak. You wouldn't use the same heat for a thin flank steak as you would for a thick porterhouse, right?

Welding is similar – different metal thicknesses require different levels of heat and wire feed speed.

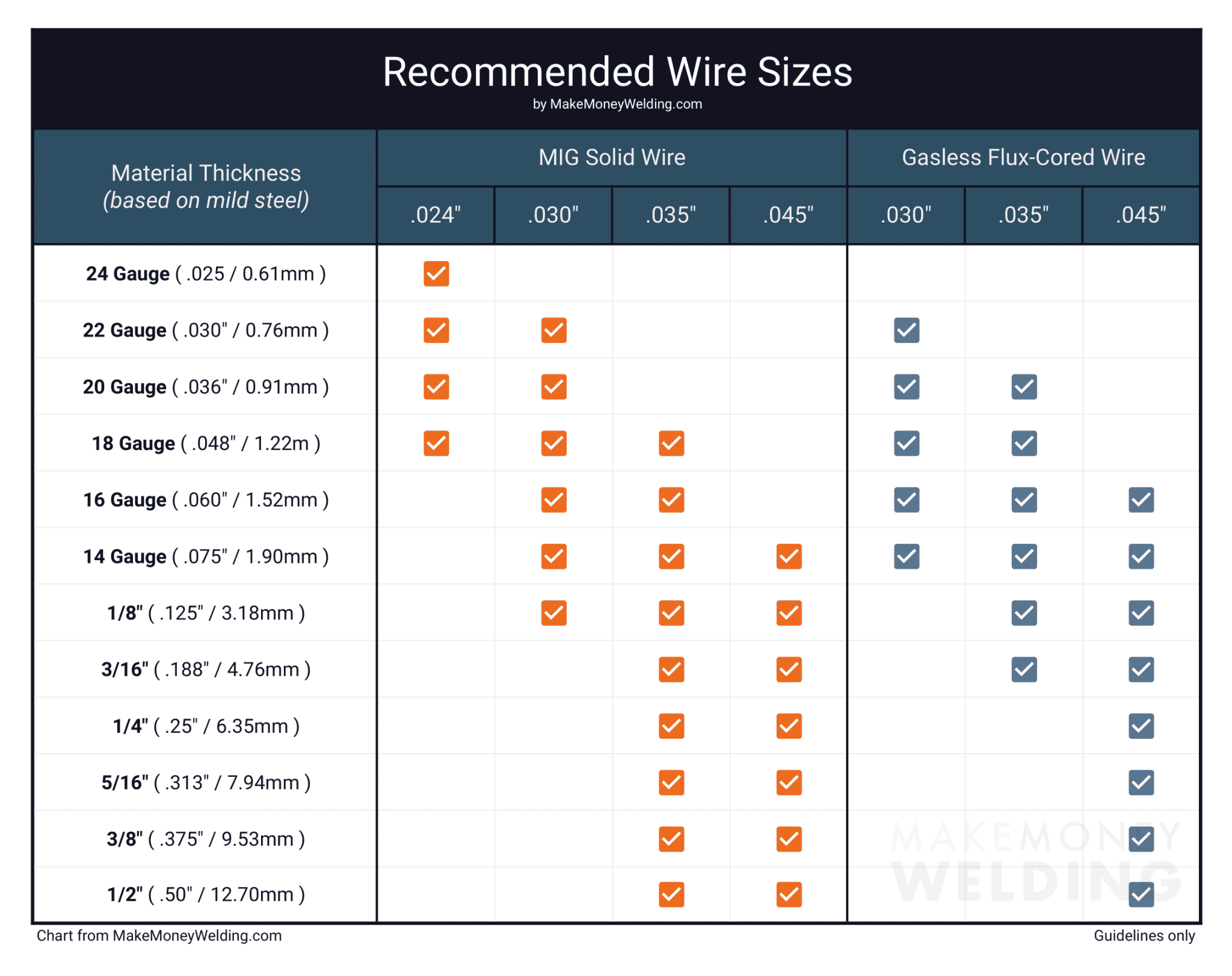

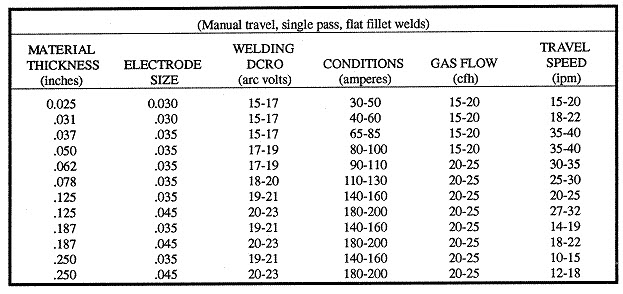

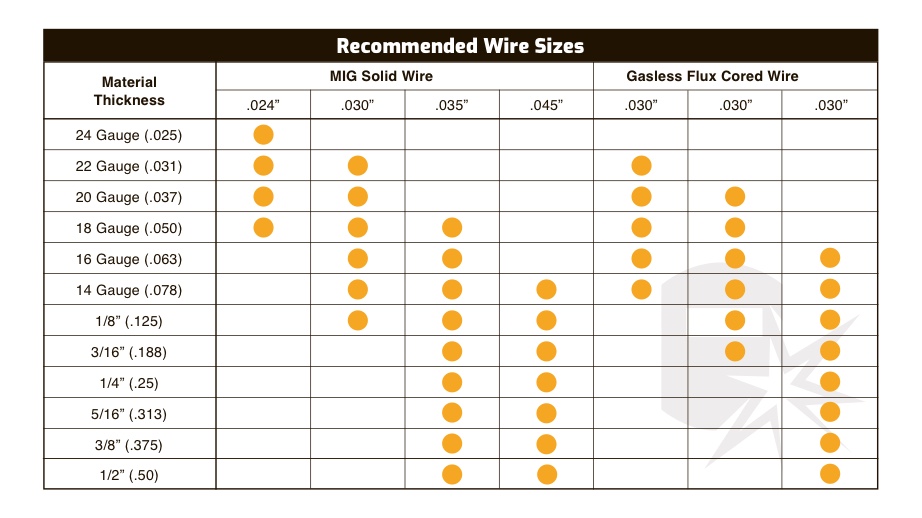

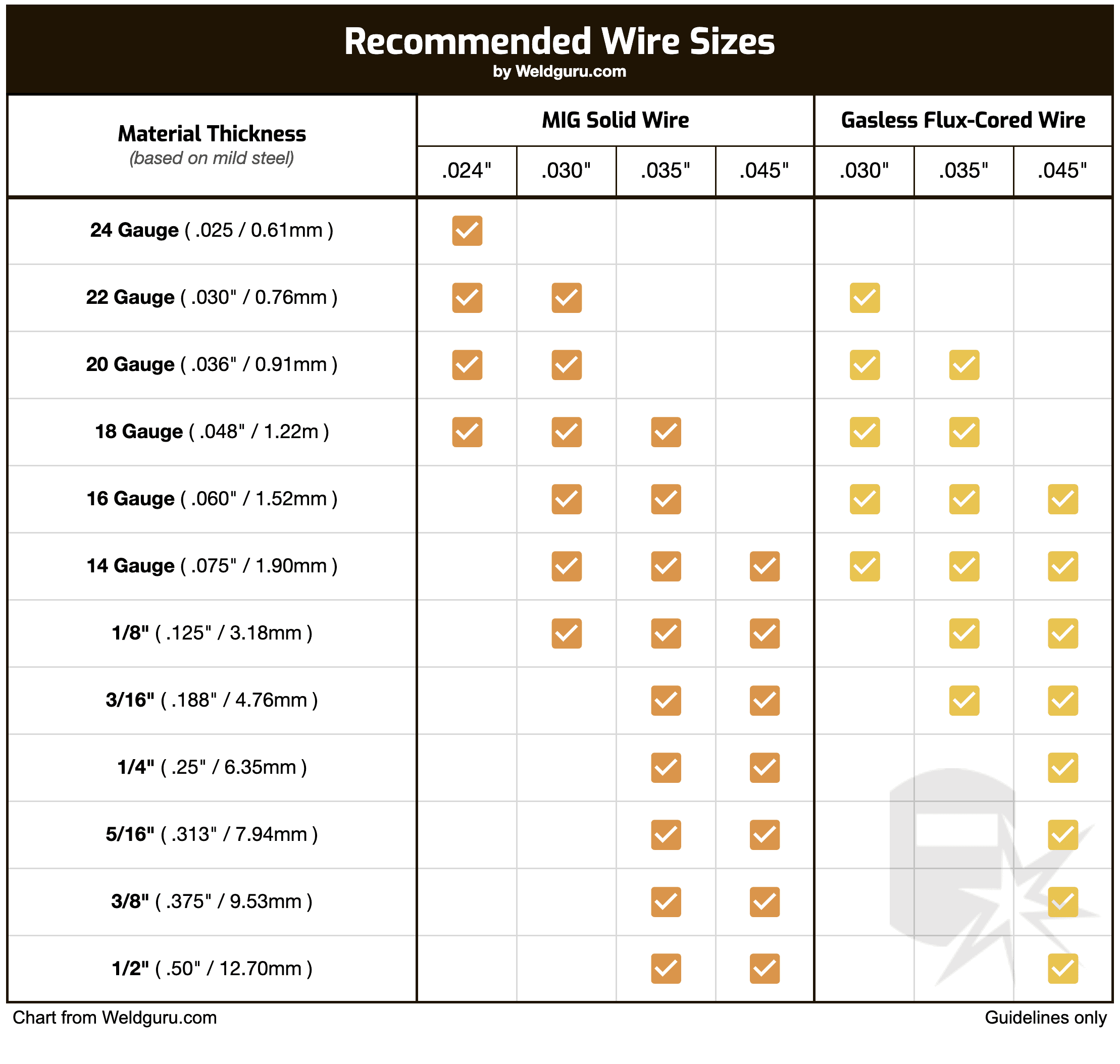

As a general rule of thumb, here's a handy cheat sheet:

- .030 wire: 18 gauge (approx. 1.2mm) to 14 gauge (approx. 2mm)

- .035 wire: 14 gauge (approx. 2mm) to 10 gauge (approx. 3.5mm)

- .045 wire: 10 gauge (approx. 3.5mm) and thicker

These are just guidelines, of course. The exact settings will depend on your welding machine, the type of metal, and your personal technique.

Experiment! That’s the best way to learn.

Other Factors to Consider

Metal type also plays a role. Welding aluminum, for example, often requires a different wire size than welding steel, even if the metal thicknesses are the same.

Aluminum wire tends to be softer and requires more finesse. It’s like trying to ice a cake with a rubber spatula – you need a gentle touch.

The type of shielding gas you're using can also influence your wire choice. Different gases create different arc characteristics, which can affect the way the wire melts and penetrates the metal.

Your Welding Machine Matters

Your welding machine's amperage range is crucial. Make sure the wire size you choose is compatible with your machine's capabilities. You can't expect a small 110V welder to handle .045 wire effectively.

It's like trying to tow a boat with a scooter – it's just not going to happen.

Check your welder's manual for recommended wire sizes and amperage settings. The manufacturer knows best (usually!).

Tips for Success

Start with the recommended settings and fine-tune them as needed. Every welding machine is a little different, and your personal technique will also play a role. Don’t be afraid to experiment!

Properly clean your metal before welding. Remove any rust, paint, or grease to ensure a clean and strong weld. It's like washing your hands before eating – it makes a big difference.

Maintain a consistent travel speed and arc length. This will help you create a uniform and aesthetically pleasing weld. Think of it like painting a fence – you want smooth, even strokes.

Practice, practice, practice! The more you weld, the better you'll become at choosing the right wire size and achieving consistent results. It’s like learning to ride a bike – you might fall a few times, but eventually you'll get the hang of it.

Don’t be afraid to ask for help! There are plenty of experienced welders out there who are happy to share their knowledge and expertise. Online forums and welding supply stores are great resources.

Wrapping It Up

Choosing the right MIG welding wire size doesn't have to be a daunting task. With a little knowledge and experimentation, you'll be welding like a pro in no time. Remember, .030 for thin stuff, .035 for most things, and .045 for the heavy duty projects.

So go forth and conquer those metal projects! Happy welding!

And remember: Safety first! Always wear proper eye protection and gloves when welding. We want you to weld like a champion, not look like you wrestled a bear wearing only sunglasses.