Ever stared at a beautifully crafted bicycle frame, a gleaming piece of jewelry, or even the plumbing under your sink and wondered, "How did they *stick* that together?" Well, chances are, if it looks incredibly neat and strong, brazing might be involved. And that brings us to the star of our show: brazing filler metal!

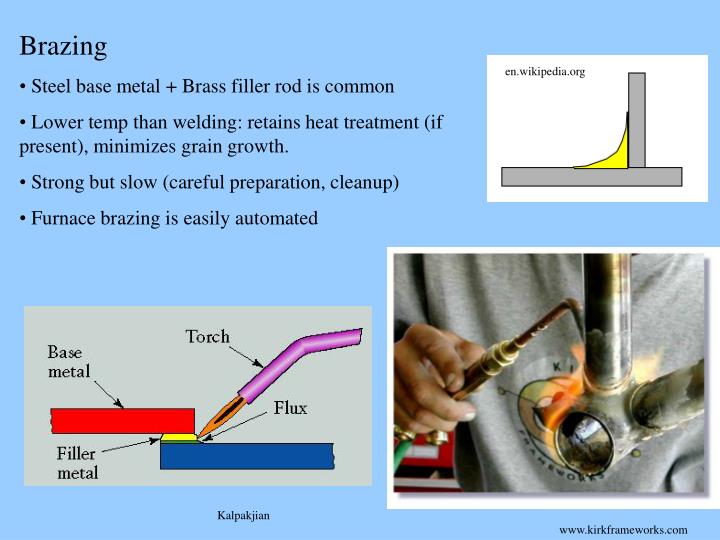

Think of brazing like a super-powered, incredibly tidy glue job for metal. But instead of Elmer's, we're using special metal alloys that melt at a lower temperature than the metals we're joining.

What exactly *is* this magical metal glue made of? That's where things get interesting, and surprisingly diverse!

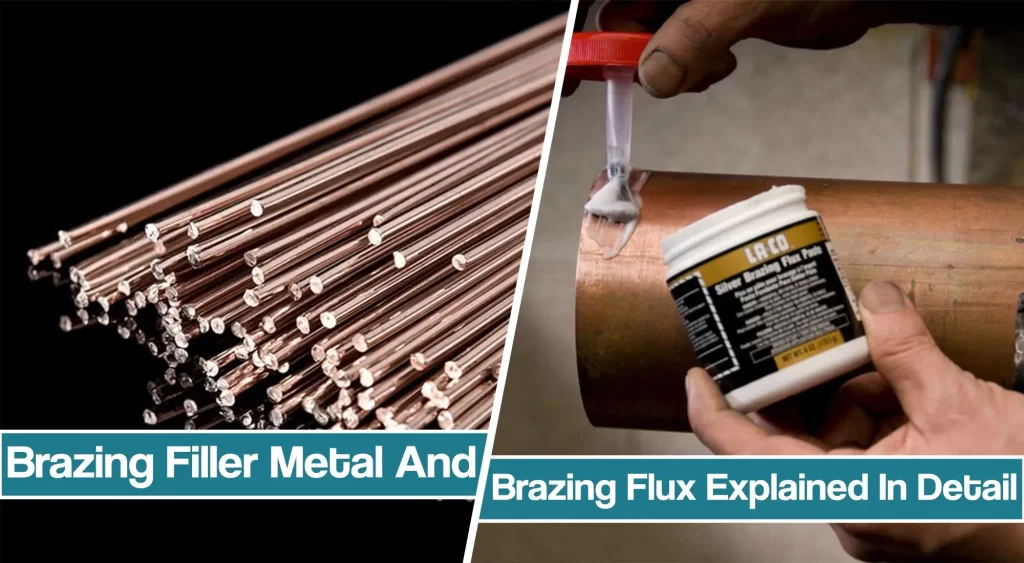

The Copper Crew: The OG Brazing Brigade

Copper-based alloys are the granddaddies of brazing filler metals. They've been around for ages, likely used by ancient artisans to create stunning works of art and functional tools.

Imagine a Roman craftsman carefully brazing a bronze chariot fitting with a copper-zinc alloy. Talk about a historical hot take!

These copper alloys are strong, relatively inexpensive, and work wonders on many metals, including steel, copper, and nickel alloys. They're the workhorses of the brazing world, reliable and always ready to get the job done.

Silver Linings: The Shiny and Strong Option

Now we're talking bling! Silver-based brazing alloys offer superior strength and corrosion resistance. They're the superstars when you need a joint that can withstand the test of time (and maybe even a bit of salt spray).

Picture a delicate silver bracelet, each tiny link flawlessly joined with a silver-based brazing alloy. It's not just beautiful; it's built to last, thanks to the amazing properties of silver.

Silver alloys are more expensive than copper, but their superior qualities often make them worth the investment, especially for critical applications or high-end products.

Aluminum Allies: Lightweight and Mighty

Aluminum brazing alloys are the go-to choice for, you guessed it, joining aluminum parts! Think of car radiators, air conditioning units, and even some parts of airplanes.

Weight is a huge deal in these industries, and aluminum's lightweight properties, combined with the strength of brazed joints, make it a winning combination.

Brazing aluminum can be a bit trickier than other metals, often requiring special fluxes to prevent oxidation. But the results are worth it: strong, lightweight joints that can withstand demanding conditions.

Nickel Ninjas: The High-Temperature Heroes

Need to join parts that will face extreme heat? Enter nickel-based brazing alloys! These alloys are the champions of high-temperature applications, like jet engines and gas turbines.

These specialized alloys are incredibly strong and resistant to oxidation at high temperatures. They're the unsung heroes working tirelessly inside some of the most powerful machines on the planet.

They are relatively expensive, but are a must for joining stainless steel, superalloys, and other high-performance materials.

Beyond the Basics: A Sprinkle of Other Elements

Sometimes, a simple alloy just won't cut it. That's where things get really interesting, with the addition of other elements to fine-tune the properties of the brazing filler metal.

For example, adding manganese can increase strength, while silicon can improve fluidity. It's like a chef carefully adjusting a recipe to create the perfect dish… only with molten metal instead of spices!

These custom alloys are often used for highly specific applications, where precise properties are crucial for performance and reliability.

Flux: The Brazing Buddy

No discussion of brazing filler metals is complete without mentioning flux. Flux is a chemical cleaning agent. Think of it as the soap that makes brazing so good.

Flux removes oxides and other impurities from the surfaces being joined, allowing the molten brazing filler metal to flow freely and create a strong, clean bond.

Different fluxes are used for different metals, so it's crucial to choose the right flux for the job. It's like pairing the right wine with a meal – the perfect complement can elevate the entire experience!

A Word of Caution

Brazing involves working with high temperatures and potentially hazardous materials, so safety is paramount. Always wear appropriate protective gear, including gloves, eye protection, and a respirator, and work in a well-ventilated area.

Respect the heat, respect the materials, and you'll be well on your way to creating beautiful and strong brazed joints!

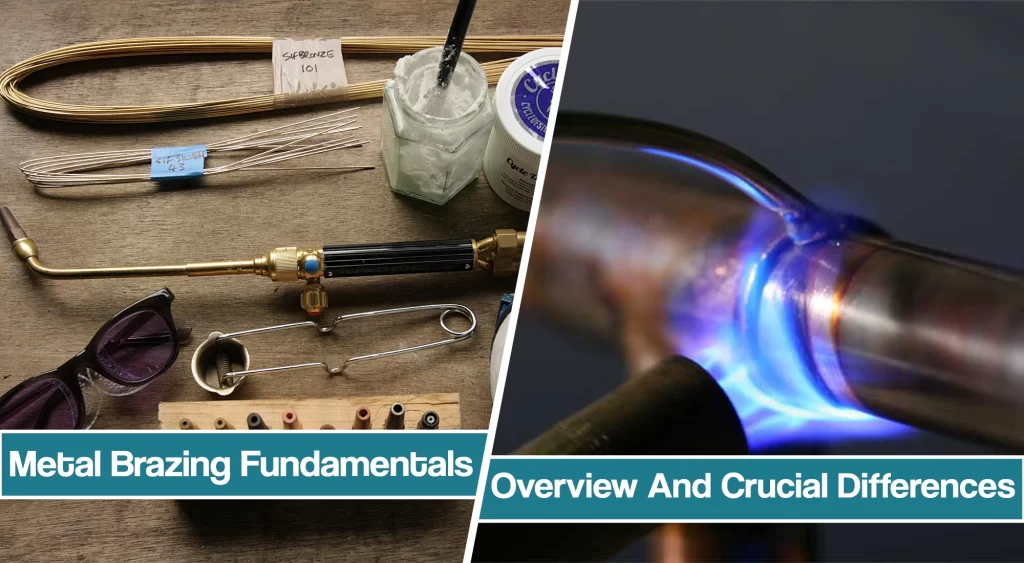

The Art of the Join

Brazing is more than just sticking metal together; it's an art form. A skilled brazer can create joints that are not only strong but also visually appealing.

Think of a handcrafted bicycle frame, with perfectly smooth brazed joints that seamlessly blend the tubes together. It's a testament to the skill and artistry of the brazer.

And because of these different metals, the art of brazing ensures your bike can withstand bumpy roads.

Brazing: It's All Around Us!

From the mundane to the magnificent, brazing plays a vital role in countless industries and applications. It's a silent workhorse, quietly ensuring that things stay together, even under extreme conditions.

The next time you admire a beautifully crafted object or rely on a piece of machinery, take a moment to appreciate the power of brazing and the ingenuity of the brazing filler metals that make it all possible.

And remember, behind every strong joint, there's a carefully chosen alloy working hard to keep things together, sometimes in the most surprising and heartwarming ways.