Ever wonder why skyscrapers stand tall or why a guitar string twangs just right? A big part of the answer lies in a fascinating property of materials called Young's Modulus. Don't let the name scare you – it's a surprisingly simple concept that helps us understand how stiff or flexible things are, especially steel! Understanding Young's Modulus for steel unlocks a peek into the world of engineering and materials science, making everyday objects and structures a whole lot more interesting.

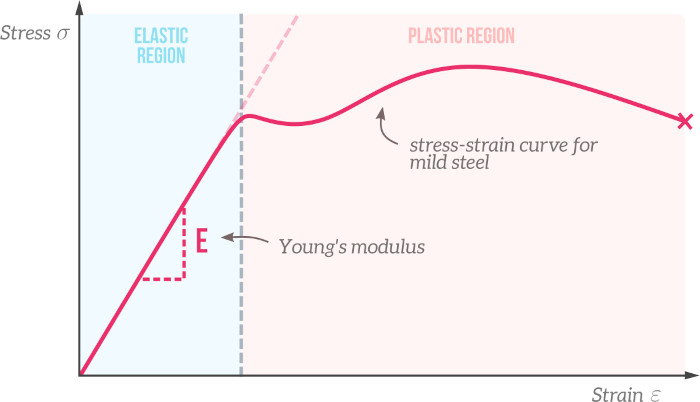

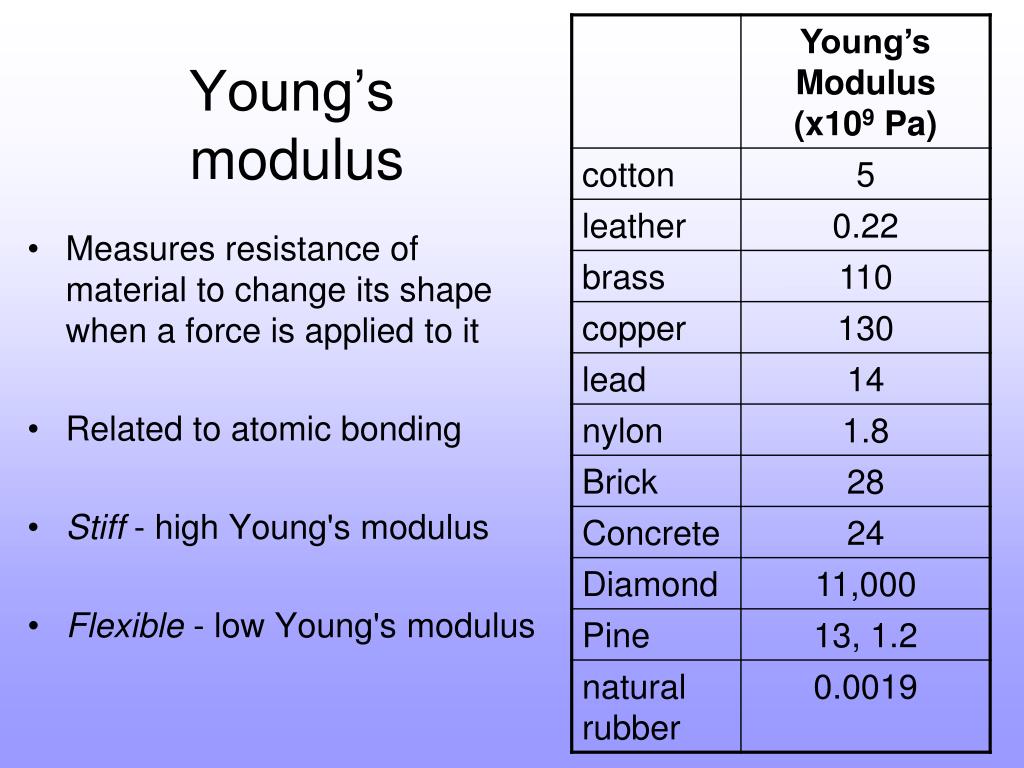

So, what's the big deal? Well, Young's Modulus essentially tells us how much a material will stretch or compress under a certain amount of force. Think of it like this: imagine pushing on a rubber band versus pushing on a steel ruler. The rubber band stretches easily, while the steel barely moves. That's because steel has a much higher Young's Modulus than rubber. It's inherently stiffer.

For beginners, understanding Young's Modulus provides a foundation for appreciating the materials around you. It explains why bridges don't collapse under the weight of cars and trucks (they're made with strong, stiff materials like steel!) and why bike frames can handle bumpy rides.

For families and hobbyists, knowing a bit about Young's Modulus can be incredibly practical. Building a birdhouse? Choosing the right screws for a project? Understanding how wood and metal behave under stress can help you make informed decisions, ensuring your creations are strong and durable. For instance, when building a small swing set, knowing that steel support beams are superior to wood regarding tensile strength is critical to safety and longevity.

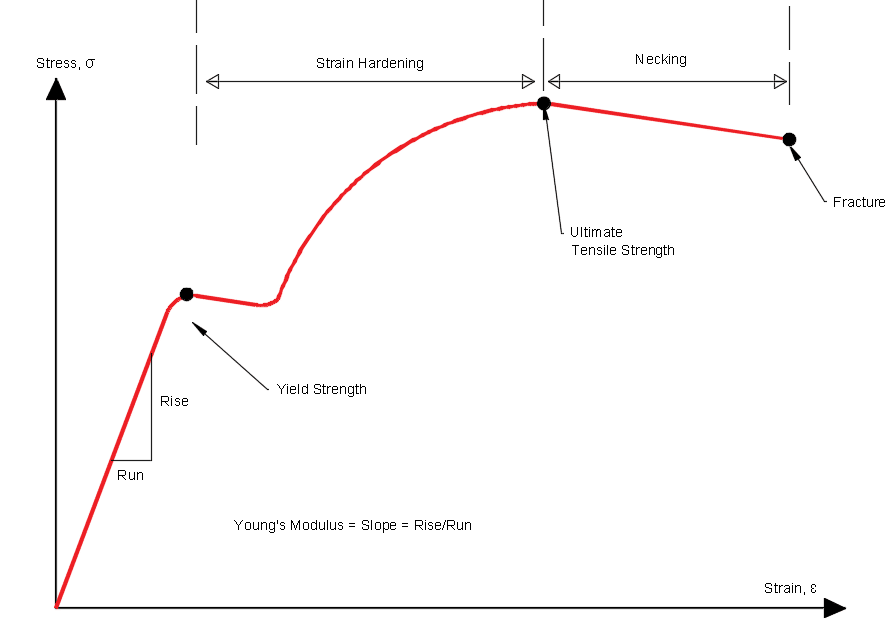

For more advanced learners, Young's Modulus is crucial for calculating stresses and strains in structures. Engineers use it to design everything from airplanes to bridges to surgical implants. The standard unit for Young's Modulus is Pascals (Pa) or pounds per square inch (psi). For most types of steel, Young's Modulus is around 200 Gigapascals (GPa) or 29 million psi. That's why steel is such a reliable material for construction.

There are, of course, variations. Different types of steel alloys have slightly different Young's Moduli. Stainless steel, for example, might be a little less stiff than high-carbon steel. Temperature can also play a role – steel tends to become slightly less stiff at higher temperatures. These nuances are crucial for engineers when designing structures that will operate in extreme environments.

Want to get started understanding this better? Here are a few simple tips:

- Experiment with everyday objects: Try bending different materials and observing how easily they deform. Which is easier to bend, a plastic ruler or a metal one?

- Watch engineering documentaries: Many documentaries explore the science behind structures and materials, often touching on concepts like Young's Modulus.

- Research different steel types: Explore the properties of different steel alloys and how their compositions affect their stiffness.

Understanding Young's Modulus for steel might seem like a complex topic at first, but it's really about appreciating the inherent properties of materials and how they impact the world around us. It's a fascinating glimpse into the science that makes our world strong and reliable, and hopefully, you've found it a little less intimidating and a lot more interesting!