Ever dreamt of slicing through a birthday cake with a laser beam? Well, while lasers are cool (and used in all sorts of amazing ways), there's another cutting-edge tool that uses something far more fundamental: water! And not just a gentle stream, but a super-powered jet of water.

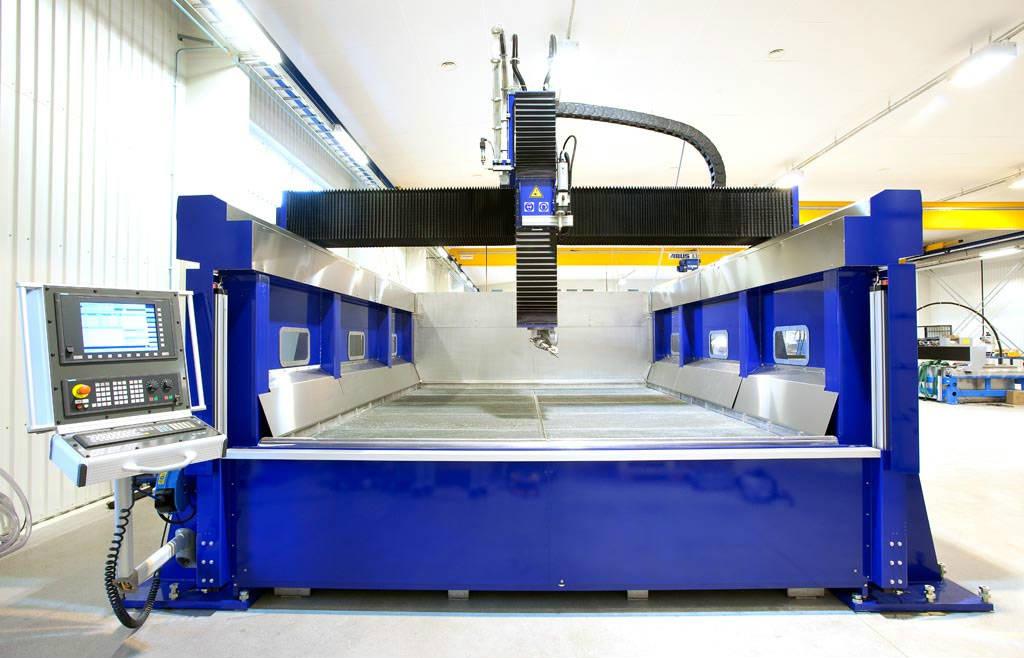

Enter the water jet cutting machine. Sounds like something out of a superhero comic, doesn't it? It's basically a high-tech squirt gun, but instead of soaking your friends, it precisely cuts through materials like metal, stone, glass, and even food!

The Magic Behind the Mist

Imagine your garden hose. Now, crank up the pressure until it could cut through steel. That’s the basic idea behind a water jet. These machines use intensely high pressure to force water through a tiny nozzle, creating a narrow, focused stream.

The pressure is so intense that it can reach over 60,000 PSI (pounds per square inch). That's like having the weight of several elephants balanced on your fingertip! Think about that next time you’re casually watering your plants.

For some materials, just water isn't enough. It needs a little extra "oomph."

Adding Abrasives: Turning Water into a Grinding Force

Think of adding sand to water. That's pretty much what happens in an abrasive water jet. Tiny abrasive particles, like garnet (yes, the gemstone!), are mixed into the water stream.

These particles act like microscopic chisels, grinding away at the material being cut. It's like a super-powered sandblaster, but with the precision of a surgeon.

This abrasive addition allows the water jet to cut through incredibly tough materials like titanium, hardened steel, and even bulletproof glass.

More Than Just Cutting: A Gentle Giant

What's truly amazing about water jet cutting is its versatility and the relatively gentle impact it has on the material being cut.

Unlike laser cutting or plasma cutting, water jet cutting doesn't produce a "heat-affected zone." This means the material isn't warped or altered by extreme temperatures, preserving its integrity.

This is crucial for industries where material properties are paramount, such as aerospace or medical device manufacturing.

No Nasty Fumes or Sparks: An Eco-Friendly Option

Water jet cutting is a surprisingly clean and green process. It doesn't produce harmful fumes or sparks, making it a safer and more environmentally friendly alternative to traditional cutting methods.

The water used in the process can often be recycled, further reducing its environmental footprint.

So, you can have precise cutting with a clearer conscience. It's a win-win!

From Art to Industry: The Water Jet's Diverse Applications

Water jet cutting isn't just for heavy industry. Its precision and versatility have made it a valuable tool in a wide range of fields.

Artists use it to create intricate sculptures and mosaics. Architects use it to cut custom stone flooring and decorative panels.

Even the food industry uses water jets to precisely cut portions of meat, vegetables, and even frozen pizzas! Imagine a robot chef wielding a water jet with ninja-like precision.

Unexpected Water Jet Wonders

Think about the personalized tile in your bathroom, chances are it was crafted using water jet cutting. Or that intricate metal sign outside your favorite coffee shop. The possibilities are endless.

Water jet cutting is used in the automotive industry to create prototype parts and custom car modifications. Imagine the possibilities!

And speaking of imagination, Hollywood special effects teams use water jets to create stunning visual effects. Remember that scene where a car is sliced in half? There's a good chance a water jet was involved.

The Future is Wet: Water Jet Innovations

The world of water jet cutting is constantly evolving, with new innovations emerging all the time. Researchers are exploring ways to improve the speed, precision, and efficiency of water jet systems.

They are also developing new abrasive materials and nozzle designs to expand the range of materials that can be cut.

Imagine a future where water jets are used to perform delicate surgical procedures, create personalized prosthetics, or even build entire structures out of thin air! Okay, maybe not thin air, but you get the idea.

The Humble Hose Gets an Upgrade

From its humble beginnings as a simple cutting tool, the water jet has become a sophisticated and versatile technology with applications in countless industries.

It's a testament to human ingenuity and our ability to harness the power of nature – in this case, the power of water – to create innovative solutions.

So, the next time you turn on the faucet, take a moment to appreciate the incredible potential of water. You never know, it might just inspire you to invent the next big thing!

The Take Away

So, the next time you hear about a water jet cutting machine, remember it's more than just a high-powered squirt gun. It's a testament to the power of water, the ingenuity of engineers, and the endless possibilities of technology.

It is a gentle giant capable of incredible feats, from creating delicate works of art to shaping the future of manufacturing.

Who knew something as simple as water could be so extraordinary?