Ever wonder how skyscrapers stand so tall, or how bridges can bear the weight of countless cars? A big part of the answer lies in a fundamental property of steel called its yield stress. It might sound like something only engineers need to worry about, but understanding yield stress is surprisingly relevant – and even a little bit fun – when you start to see its influence all around you.

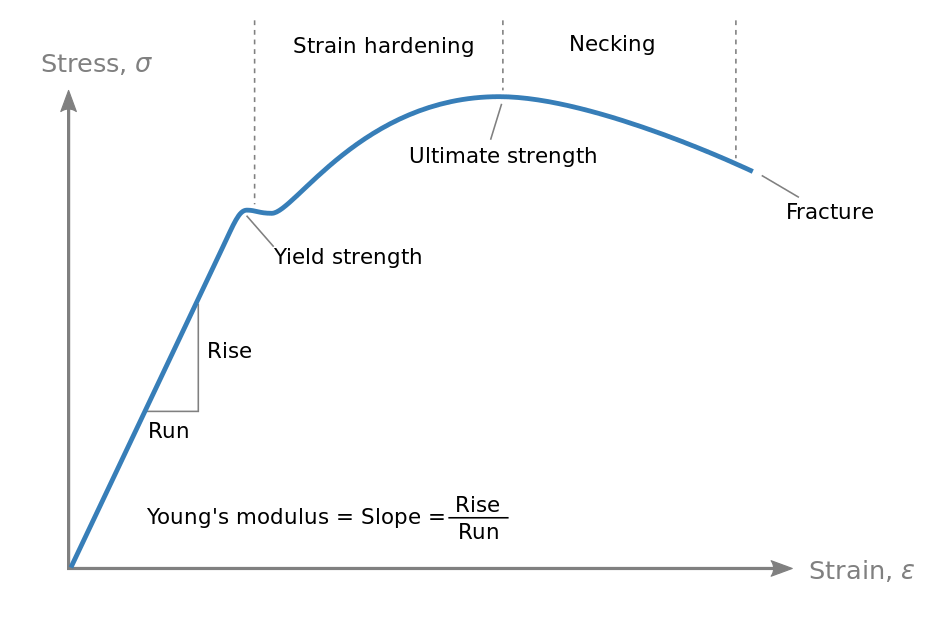

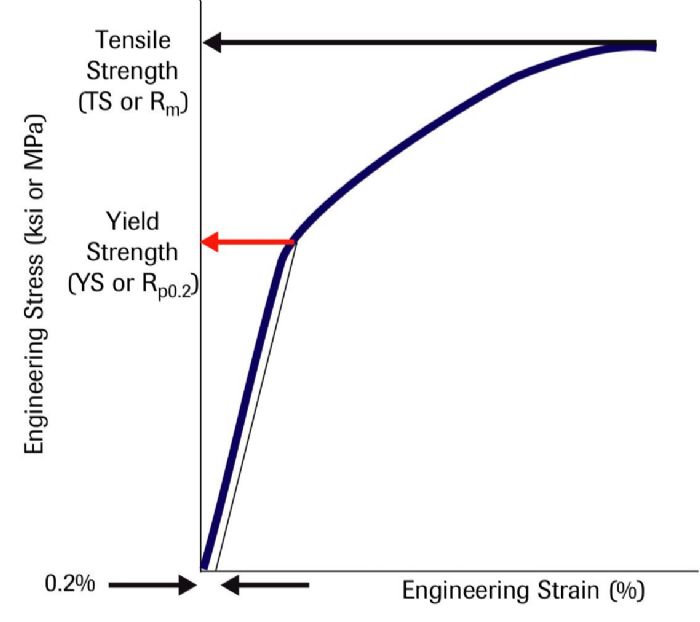

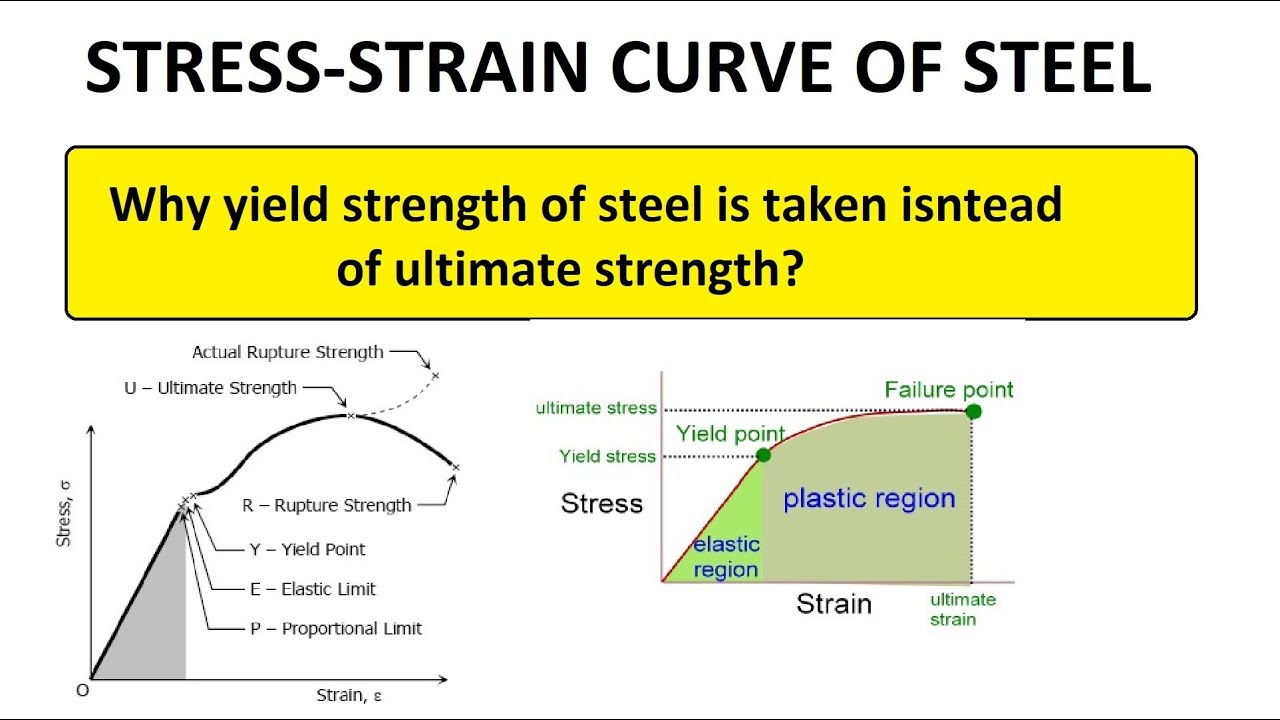

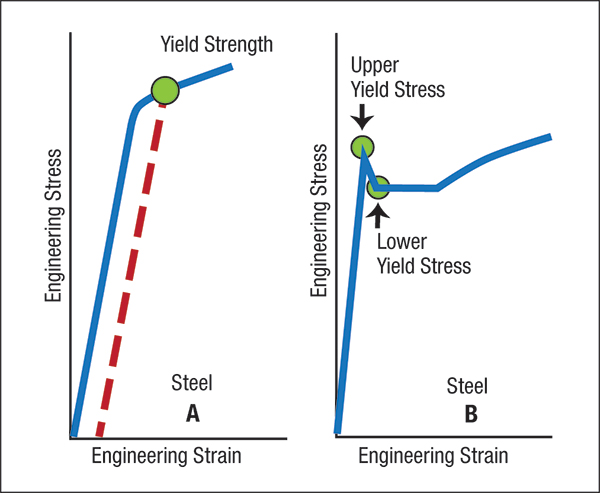

So, what exactly is yield stress? Imagine bending a paperclip. At first, it bends easily, but if you bend it too far, it stays bent. That point where the paperclip goes from bending back to its original shape to staying permanently deformed is closely related to yield stress. In more technical terms, yield stress is the amount of stress (force per unit area) a material, like steel, can withstand before it starts to undergo permanent deformation. Think of it as the material's resistance to being permanently bent, stretched, or otherwise changed.

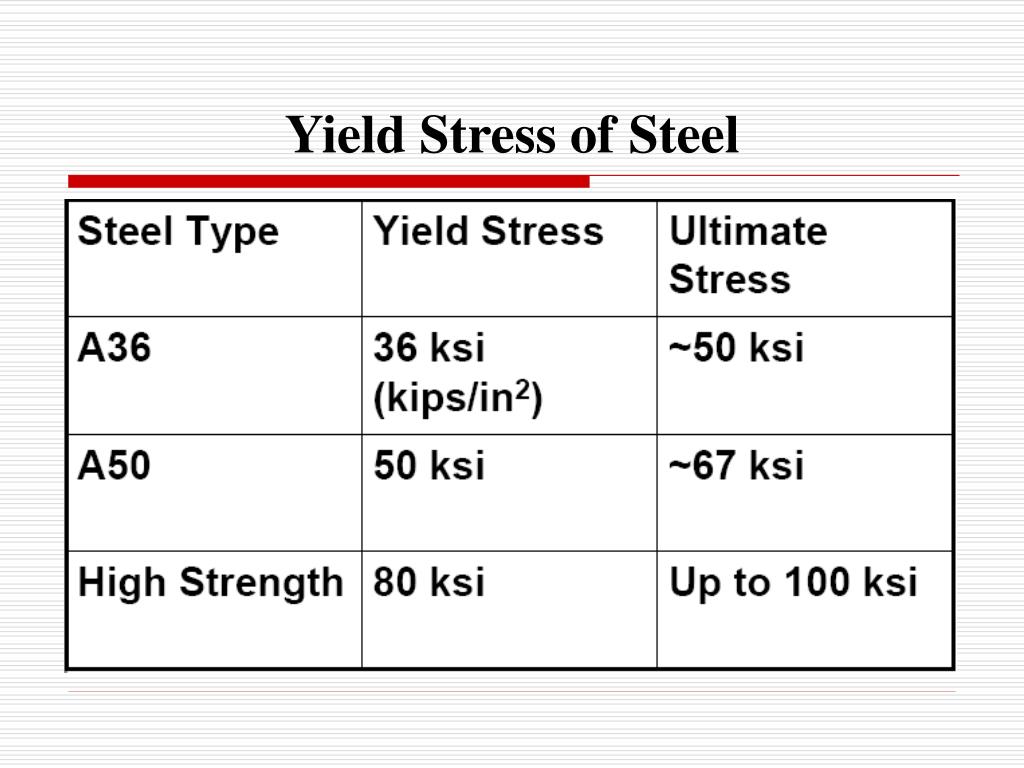

Why is yield stress so important? Well, it's crucial for engineers to know the yield stress of steel (and other materials) when designing structures. Knowing this value allows them to calculate how much load a structure can bear before it starts to permanently deform or, worse, fail. Bridges, buildings, cars, even the frames of your glasses – all are designed with the yield stress of their materials in mind. The benefit is safety and durability. By carefully considering yield stress, engineers can ensure that structures are strong enough to withstand the forces they will encounter, making them safe and reliable for everyday use.

You might not realize it, but yield stress concepts are used in education quite a bit. Physics and engineering students perform experiments to measure the yield stress of different materials. They might use tensile testing machines that pull on a material until it deforms, or bending tests to see how much force it takes to permanently bend a beam. Even at a simpler level, understanding how different types of clay behave when you try to mold them involves an intuitive grasp of yield stress – some clays are easier to deform permanently than others!

In daily life, think about opening a soda can. The small piece of aluminum you pull on has been carefully designed to have a low enough yield stress to be easily torn, yet strong enough to hold the tab in place. Or consider the spring in a retractable pen. It's designed to withstand repeated compression without permanently deforming, thanks to the careful selection of a material with an appropriate yield stress. Even the tines of a fork are designed to bend slightly under pressure but return to their original shape, preventing them from becoming permanently bent out of shape after repeated use.

Want to explore yield stress in a simple way? Grab some different types of wire – copper, steel, aluminum. Try bending them. Which is easiest to bend permanently? Which springs back the most? This simple experiment can give you a feel for how different materials have different yield strengths. You can also try bending different thicknesses of the same material. Does a thicker piece resist permanent deformation more than a thinner piece? Exploring these questions is a fun way to get a hands-on understanding of this essential material property.