Okay, so you're looking at a stress-strain curve, huh? Fancy! Don't worry, it's not as scary as it looks. Think of it as a material's diary, recording how it reacts to being pulled and pushed. And somewhere on that diary, there's a thing called the proportional limit. Let's unpack it, shall we?

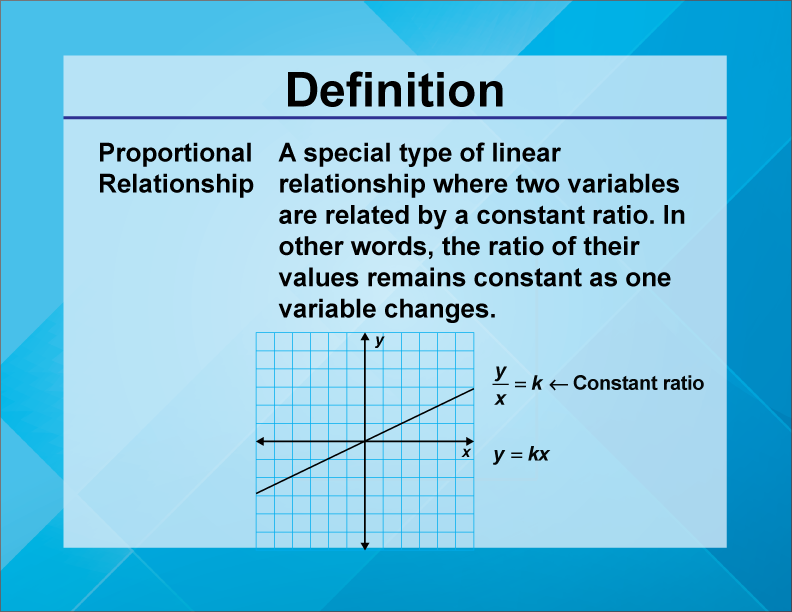

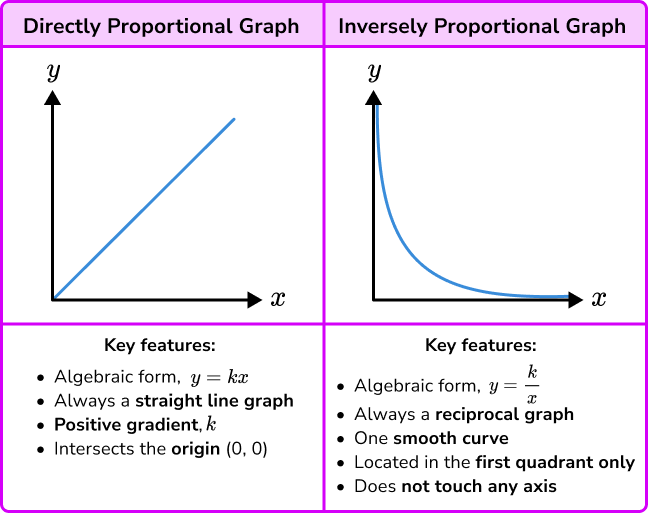

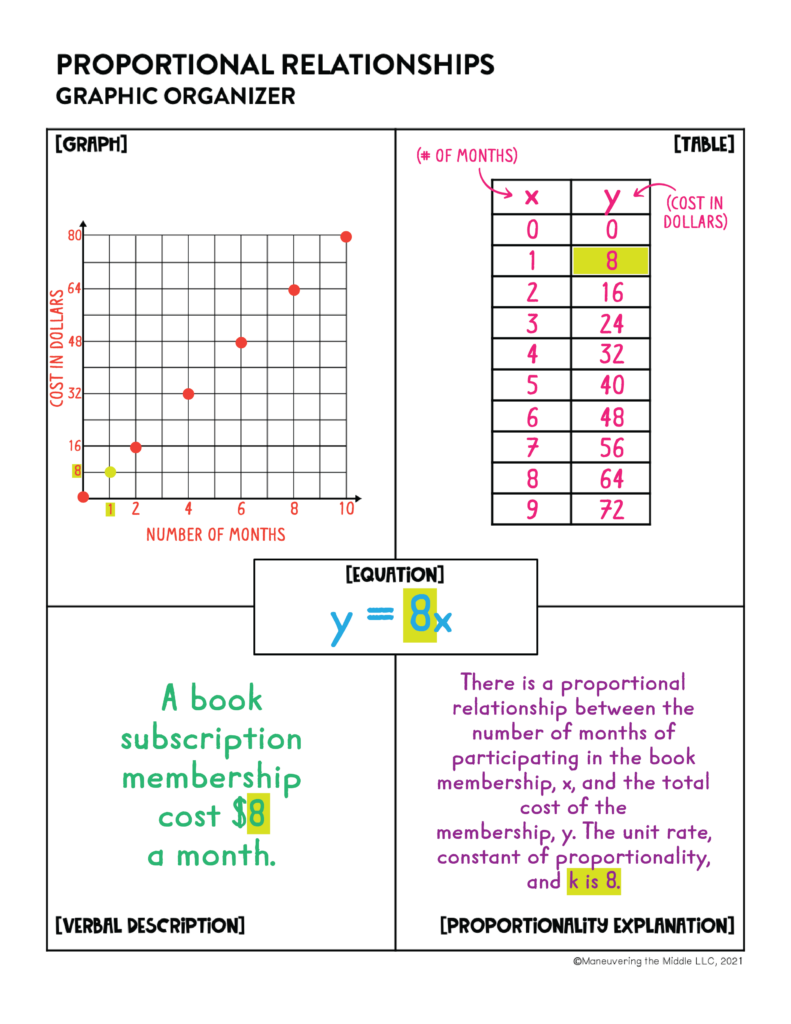

Basically, the proportional limit is like the material's "happy place." It's the point up to which stress and strain are, well, proportional! What does that mean, you ask? Great question! It means if you double the stress (the force you're applying), you double the strain (how much it deforms). Simple as that!

Think of it like this: you stretch a rubber band a little, it stretches a little. You stretch it twice as much, it stretches twice as much... *until it doesn't*! That point where it *stops* behaving so nicely? You guessed it – somewhere beyond the proportional limit.

Visually, on the stress-strain curve, the proportional limit is usually that point where the line *stops* being straight. It starts to curve off, signaling that things are getting a little... complicated. You know, like when you try to explain quantum physics to your grandma.

So, why should I care?

Good question! Why *should* you care? Well, for starters, it's crucial for engineers. Imagine designing a bridge or a building. You need to know how much stress the materials can handle *before* they start to permanently deform. You don't want your bridge sagging, do you? (Unless you're going for that "artistic" look, I guess.)

The proportional limit helps engineers ensure that structures are safe and won't undergo permanent changes under normal loading. In other words, it helps prevent disasters! No pressure or anything.

Think of it like the red line on your car's tachometer. You *can* push past it, but you risk damaging the engine. The proportional limit is the material's equivalent of that red line.

What happens *after* the Proportional Limit?

Ooh, things get interesting! Once you exceed the proportional limit, the material enters a region of **non-linear** behavior. That basically means that strain is no longer proportional to stress. Surprise! The curve starts to bend, and the material might start experiencing plastic deformation.

Plastic deformation is when the material undergoes a *permanent* change in shape. It's like bending a paperclip. It doesn't spring back to its original form, does it? That’s plastic deformation at work.

Beyond the proportional limit, you'll find other interesting points on the stress-strain curve, like the elastic limit (where permanent deformation *begins*), the yield strength (where significant plastic deformation occurs), and the ultimate tensile strength (the maximum stress the material can handle before it starts to neck down and break). But those are stories for another coffee break!

Let's just say, the proportional limit is a good place to stop. It's the line in the sand that separates elastic (reversible) behavior from potentially damaging plastic behavior. Cross it at your own risk! (Unless you're a metallurgist, then go wild!).

So, there you have it! The proportional limit, demystified. Now you can impress your friends at parties with your newfound knowledge of material science. (Or, you know, just use it to understand why your desk chair is starting to creak.)

Now, about that coffee refill...