Hey friend! Ever stressed about things going WRONG? Like, catastrophically wrong? We've all been there. But what if I told you there's a way to (kinda) predict the future…of failure? Enter: FMEA!

FMEA: Your Crystal Ball (But for Problems)

FMEA stands for Failure Mode and Effects Analysis. Sounds scary, right? Relax! It's basically a fancy way to say "Let's brainstorm all the ways this thing could break, and how bad it would be if it did." Think of it as detective work, but instead of solving a crime, you're preventing one.

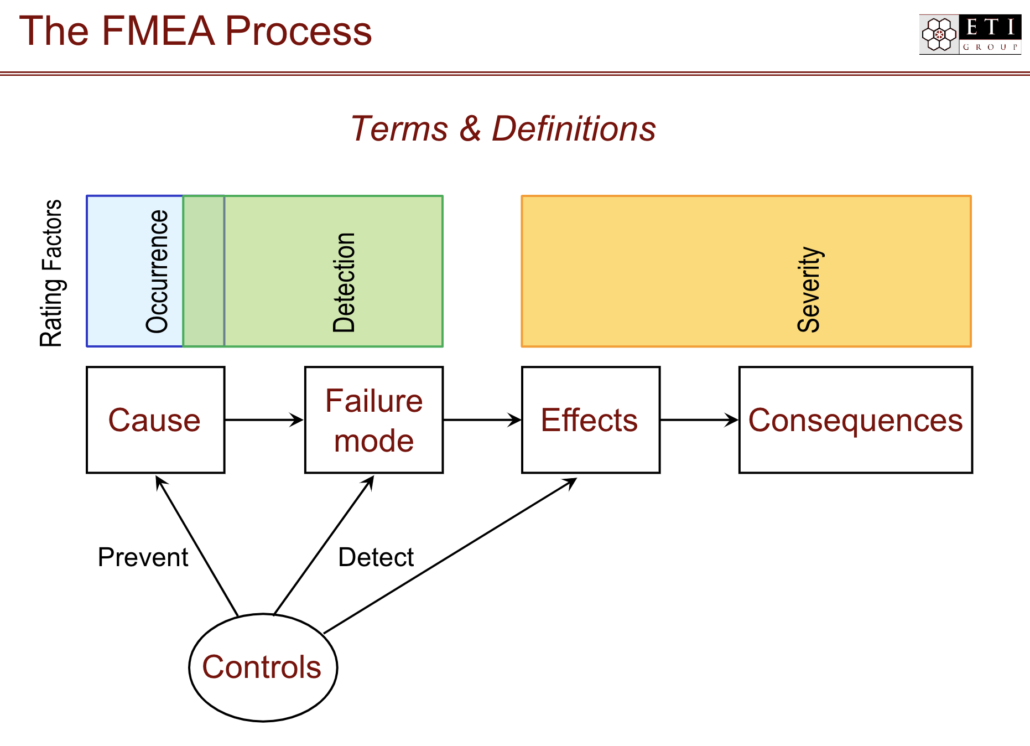

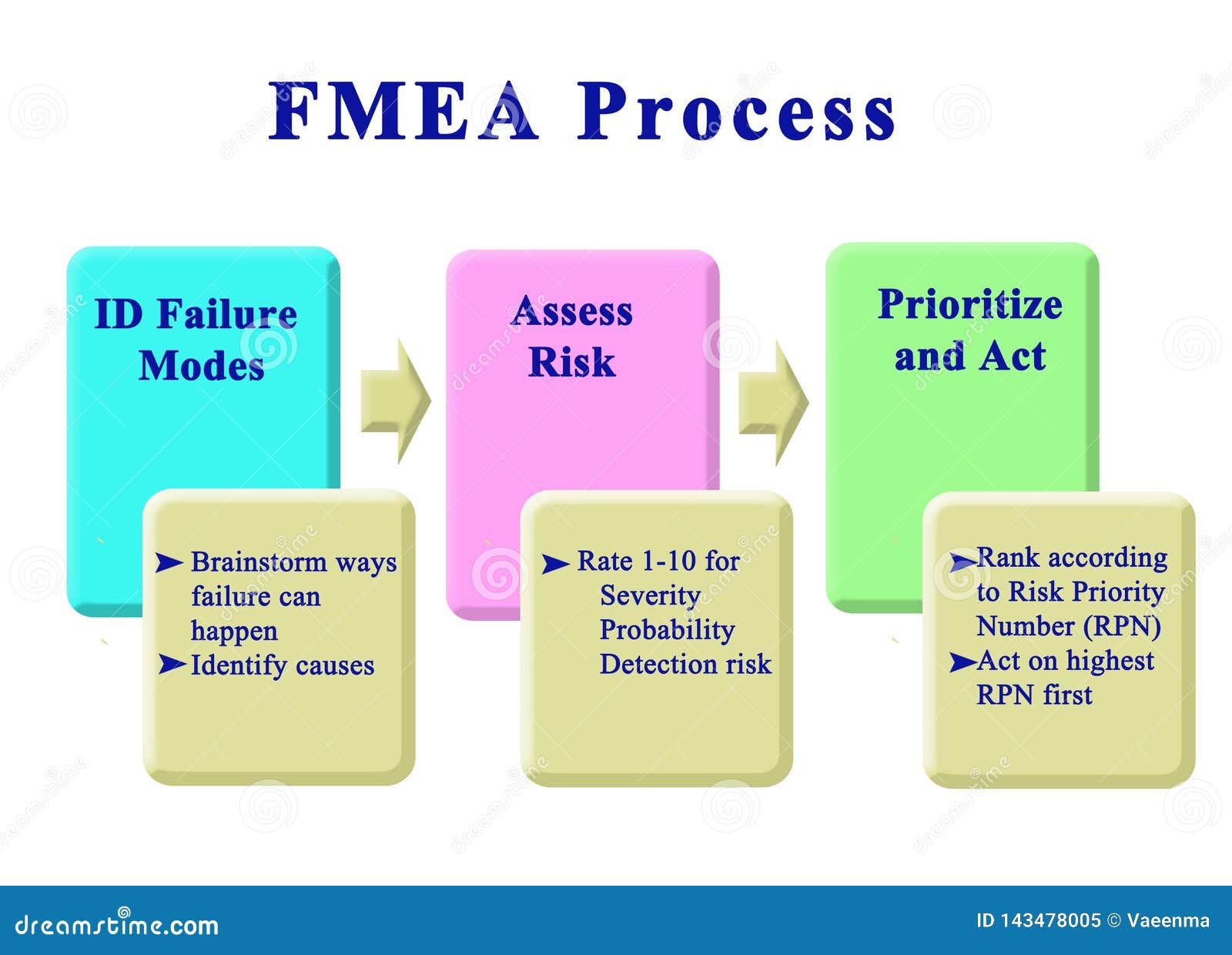

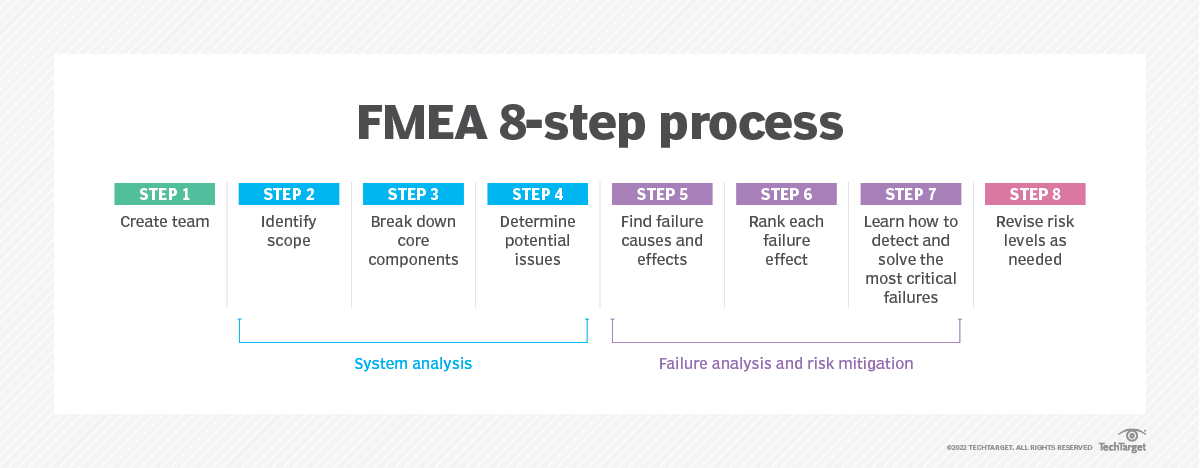

It's a structured, systematic approach to identify potential failures in a design, process, or service. Then, you get to rate how severe, likely, and detectable each failure is. It's like playing a game of "What If?" with serious consequences (hopefully not *real* consequences, thanks to FMEA!).

Why Bother? Is it Worth the Hassle?

Absolutely! Imagine launching a new product and it immediately flops because…well, because you didn't think about the obvious things that could go wrong. FMEA helps you avoid these epic fails. Here's why you should care:

- It's proactive: Catch problems before they happen, saving you time, money, and headaches.

- It's comprehensive: Forces you to think about EVERYTHING that could go wrong. No stone unturned!

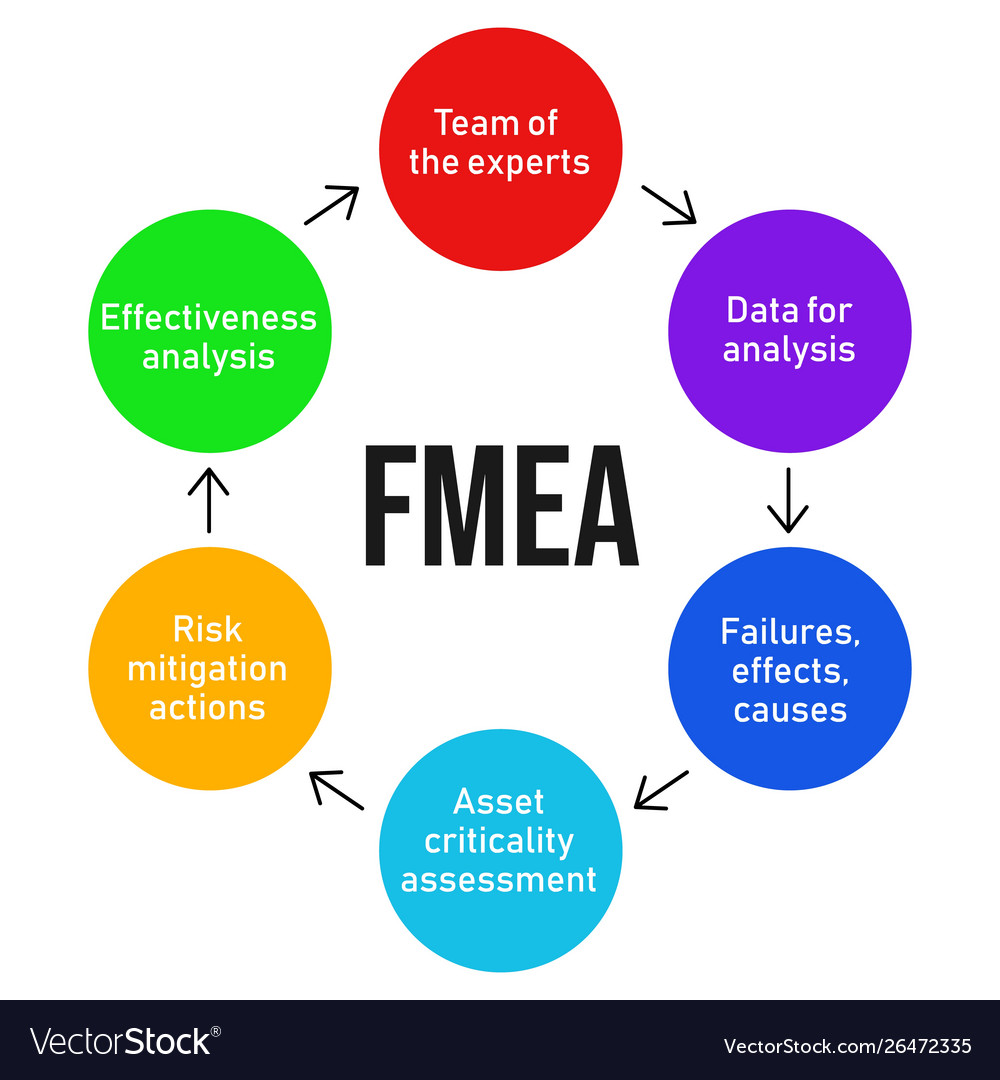

- It's collaborative: It brings different perspectives together – engineers, designers, marketers, even your quirky Uncle Joe if he has relevant insights!

- It prioritizes: Helps you focus on the most critical risks first. Don't sweat the small stuff!

Let's Get Real: An Example!

Okay, enough theory. Let's say we're designing a self-folding laundry machine. Pretty cool, huh? But what could go wrong?

Failure Mode: The robotic arm gets stuck.

Effect: Clothes get damaged, machine stops working, customer gets super angry (especially if it's their favorite shirt!).

Severity: Let's say a "7" – damaged clothes are annoying, but not life-threatening.

Occurrence: Maybe a "4" – it's possible, but not super likely. We used high-quality motors!

Detection: Hmm, a "6". It might take the user a while to notice the arm is stuck before the machine melts down and sets the house ablaze.

Now, we multiply those numbers: 7 x 4 x 6 = 168. This is our Risk Priority Number (RPN). Higher number = bigger problem.

See? You're already an FMEA pro! Now, what can we *do* about that robotic arm?

Taking Action: The Fun Part

Based on our FMEA, we need to reduce that RPN. Let's brainstorm some actions:

- Improve the motor: (Reduce Occurrence) – Invest in even *better* motors!

- Add sensors: (Improve Detection) – If the arm gets stuck, the machine shuts down automatically.

- Strengthen the arm: (Reduce Severity) – Use a more durable material for the arm.

By implementing these actions, we reduce the risk of a stuck robotic arm. We’re basically fixing a problem *before* it even exists. Pretty neat, right?

Quirky FMEA Facts!

Did you know FMEA was originally developed by the U.S. military in the 1940s? Talk about preventing catastrophic failures! (Think: planes falling out of the sky.) It has since become a staple in industries like aerospace, automotive, healthcare, and even food production. From rocket science to your morning cereal, FMEA's got your back!

There are different types of FMEAs (Design FMEA, Process FMEA, System FMEA), each tailored to specific aspects of a product or process. It's like Pokemon – gotta catch 'em all…types of failures!

FMEA: Not Just for Engineers!

Think FMEA is just for nerds in lab coats? Think again! Anyone can use this technique to improve their processes, from planning a birthday party to launching a marketing campaign. Seriously, brainstorm potential problems, assess the risk, and take action! You’ll be amazed at how much smoother things go.

So, next time you're faced with a potential problem, channel your inner FMEA guru! You might just save the world…or at least prevent a laundry-folding disaster. Isn't that awesome?