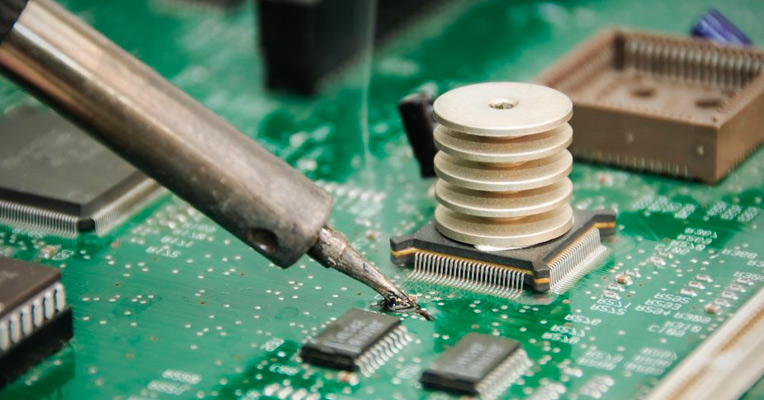

Ever seen someone waving around a wand that looks like it could brand cattle but is definitely not? Chances are, you’ve spotted a soldering iron in action! But what *is* this mysterious tool, and why is it so darn useful? Let's dive in!

Essentially, a soldering iron is a glorified, controlled heat source. Think of it like a tiny, very precise, and slightly less dramatic blowtorch. Instead of melting metal beams, though, it’s used to melt solder.

Solder? What's That?

Good question! Solder is a metallic alloy (usually tin and lead, though lead-free options are becoming more common) that has a relatively low melting point. It’s like the glue of the electronics world. But instead of being sticky, it's melty!

Imagine building with Lego. You can stack them together, but they’ll eventually fall apart, right? Solder is like a special kind of glue that, when melted, flows into the cracks and creates a strong, conductive bond. It *electrically* connects things.

So, What Does it Actually *Do*?

Here's where things get interesting. The soldering iron's main gig is creating electrical connections. Think about all the electronic devices you use daily: your phone, your computer, your TV. Inside each of these are countless tiny components connected by… you guessed it… solder!

These connections allow electricity to flow from one component to another, enabling the device to function. Without solder, it'd be like trying to play music with a broken guitar string. No signal gets through!

Soldering irons are used for:

- Electronics repair: Fixing broken wires, replacing faulty components on circuit boards, and bringing your gadgets back to life. Think of it as a mini-surgery for your electronics!

- DIY projects: Building your own circuits, robots, and other electronic creations. The possibilities are endless! Want to build your own LED sign? Soldering is your friend.

- Jewelry making: Joining metal pieces together to create beautiful and unique jewelry. A completely different application, but the principle is the same!

- Some hobbyist projects: Connecting wires in model trains, remote control cars, and other hobbies that involve electrical components.

Basically, if you need to reliably connect two electrical components, soldering is often the way to go.

Why Not Just Use Regular Glue?

Because regular glue isn't conductive! Remember, the goal is to create an electrical connection. Glue is an insulator; it *prevents* electricity from flowing. Using glue in place of solder would be like trying to fill your car with orange juice instead of gasoline. It just won’t work!

Is Soldering Difficult?

Like any skill, soldering takes practice. The first few attempts might be a bit…messy. But with a little patience and the right technique, you'll be creating perfect solder joints in no time! There are tons of tutorials online to help you get started. Think of it like learning to ride a bike. You might wobble a bit at first, but eventually, you'll be cruising along smoothly.

The key is to heat the connection (the parts you're joining) and then apply the solder to the *heated connection*, not directly to the soldering iron's tip. This ensures the solder flows properly and creates a strong, reliable bond.

Safety First!

Soldering irons get hot! Really hot! And solder, when melted, can give off fumes. So, it's important to take precautions:

- Always wear eye protection.

- Work in a well-ventilated area.

- Use a soldering iron stand to prevent accidental burns.

- Wash your hands after soldering.

Treat the soldering iron with respect, and it'll serve you well!

So, Is It Cool?

Absolutely! Soldering is a valuable skill that can open up a whole world of possibilities. From fixing your broken headphones to building your own custom electronics, the soldering iron is a powerful tool that puts you in control. Plus, there's a certain satisfaction that comes from creating something with your own hands. It's like being a tiny, electronic architect!

So, the next time you see someone soldering, remember that they're not just melting metal; they're creating connections, solving problems, and building the future, one tiny solder joint at a time. Pretty neat, huh?