Hey there, welding buddy! Ever stared at a rack of welding rods and wondered, "What's the deal with *that* one?" Today, we're diving into the world of the 7018 welding rod. Think of it as the reliable, slightly dramatic friend in your welding crew – always there when you need strength, but needing a *little* more attention.

So, What's the Big Deal with 7018?

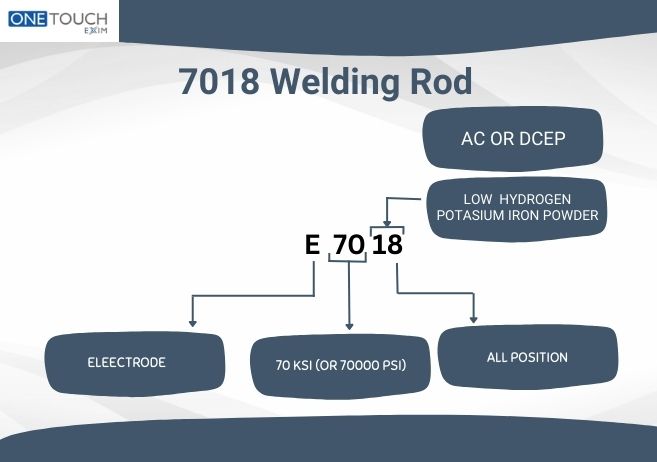

Okay, let's break down that mysterious code. The "70" means this rod has a tensile strength of 70,000 pounds per square inch (PSI). That’s a *lot* of holding power! Think of it like this: it's strong enough to hold up... well, probably not a skyscraper single-handedly (don't try it!), but definitely heavy-duty stuff.

The "1" indicates the welding position. A "1" means you can weld in all positions: flat, horizontal, vertical, and overhead. Basically, it’s versatile! This is a lifesaver when you are welding in tight spots or strange angles. It’s all about flexibility, baby!

And that "8"? This one is a bit more technical, referring to the type of coating and the welding current it needs (AC or DC). But all you really need to know is 7018 typically runs on DC+ (Direct Current Electrode Positive). Now, if all that sounds like gibberish, don't sweat it. Just remember to check your welding machine settings!

What's 7018 Used For? The Fun Part!

This is where things get interesting. 7018 is your go-to rod when you need a weld that's strong, ductile (meaning it can bend without breaking), and resistant to cracking. So, where do we use it?

- Structural Steel: Building beams, bridges, anything that needs to support a serious load? 7018 is often the choice.

- High-Strength Applications: Think heavy equipment repair, pipelines, and pressure vessels. Basically, anything where failure is *not* an option.

- Welding on Dirty or Rusty Steel: Okay, it’s not magic, but the 7018 is a bit more forgiving than some other rods when you're dealing with less-than-perfect surfaces. Still clean it if you can! Your weld will thank you.

- Thick Materials: When you are welding thick plate, this rod can give you that deep penetration you need.

Important Note: Because of its low-hydrogen properties (which help prevent cracking), 7018 is like a diva. It *needs* to be kept dry. If it absorbs moisture from the air, it can cause problems. That’s why you often see welders storing their 7018 rods in a rod oven. Think of it as a little spa for your welding rods, keeping them happy and dry.

Working with 7018: A Few Pointers

Using 7018 isn't exactly rocket science, but there are a few things to keep in mind:

- Cleanliness is Key: While 7018 is forgiving, clean your base metal as much as possible. A little prep goes a long way!

- Proper Storage: Keep those rods dry! A rod oven is ideal, but even a sealed container is better than nothing.

- Amperage Matters: Too little amperage, and you'll get poor penetration. Too much, and you'll burn through. Consult a welding chart (or your experienced welding buddy!) for the correct settings.

- Practice Makes Perfect: Like any welding rod, it takes practice to get good with 7018. Don't be afraid to experiment and try different techniques.

7018 can produce a slag (the protective coating that forms on top of the weld) that is a little harder to remove than some other rods. So, have a good chipping hammer handy! *Bang, bang, bang!*

And one final note: always wear appropriate PPE (Personal Protective Equipment) when welding. That means a welding helmet, gloves, and proper clothing. Safety first, always! We want you welding for years to come.

The End Result? A Strong, Reliable Weld

So, there you have it! The 7018 welding rod: strong, versatile, and a little bit demanding. But when you need a weld you can count on, it's a true workhorse. Remember, even though it needs some extra TLC, the results are worth it. You'll be laying down beautiful, strong beads in no time!

Now go out there and weld something amazing! And remember, even if you make a mistake, that's okay. Every weld is a learning opportunity. Keep practicing, keep learning, and keep creating!