Alright, buckle up, buttercup! We're diving headfirst into the wonderful world of TIG welding aluminum, and the burning question on everyone's lips is: "What gas do I need?" Forget rocket science, this is more like...rocket-shaped ice cream! Deliciously easy, and melts quickly if you mess up. But fear not, I'm here to guide you!

The Champion Gas: Argon

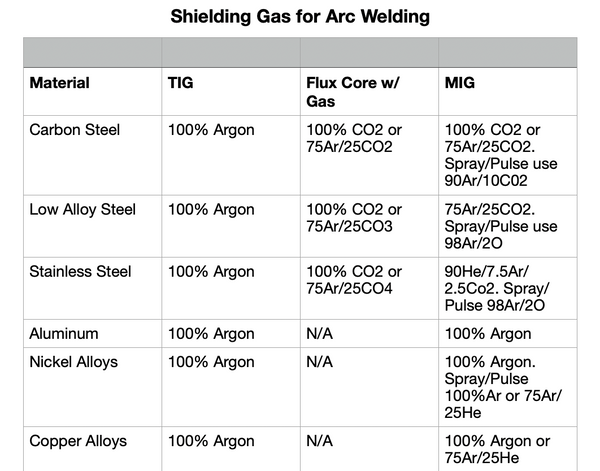

Let's cut to the chase: the reigning, undisputed champion of TIG welding aluminum is… Argon! Yep, that's the stuff. Think of it as the vanilla ice cream of shielding gases – a solid, reliable base for all your aluminum-melting adventures. Why Argon? Well, it's an inert gas, which basically means it's a total wallflower. It doesn't like to react with anything, especially not your molten aluminum. That's exactly what we want! We need a gas that'll shield our weld from the nasty atmosphere, preventing oxidation and other shenanigans that can ruin your masterpiece.

Imagine trying to bake a cake outside during a hurricane. Flour flying everywhere, rain turning your batter into soup... Disaster! Argon is like building a super-strong, weather-proof tent around your cake, keeping everything safe and sound. That's what it does for your weld pool, protecting it from the atmospheric elements.

Why Not Other Gases?

Okay, so Argon is the king. But what about the other gases hanging around at the welding supply store? Can't we use those? Well, hold your horses! Let's take a quick peek at some potential contenders and see why they're not quite up to the aluminum challenge:

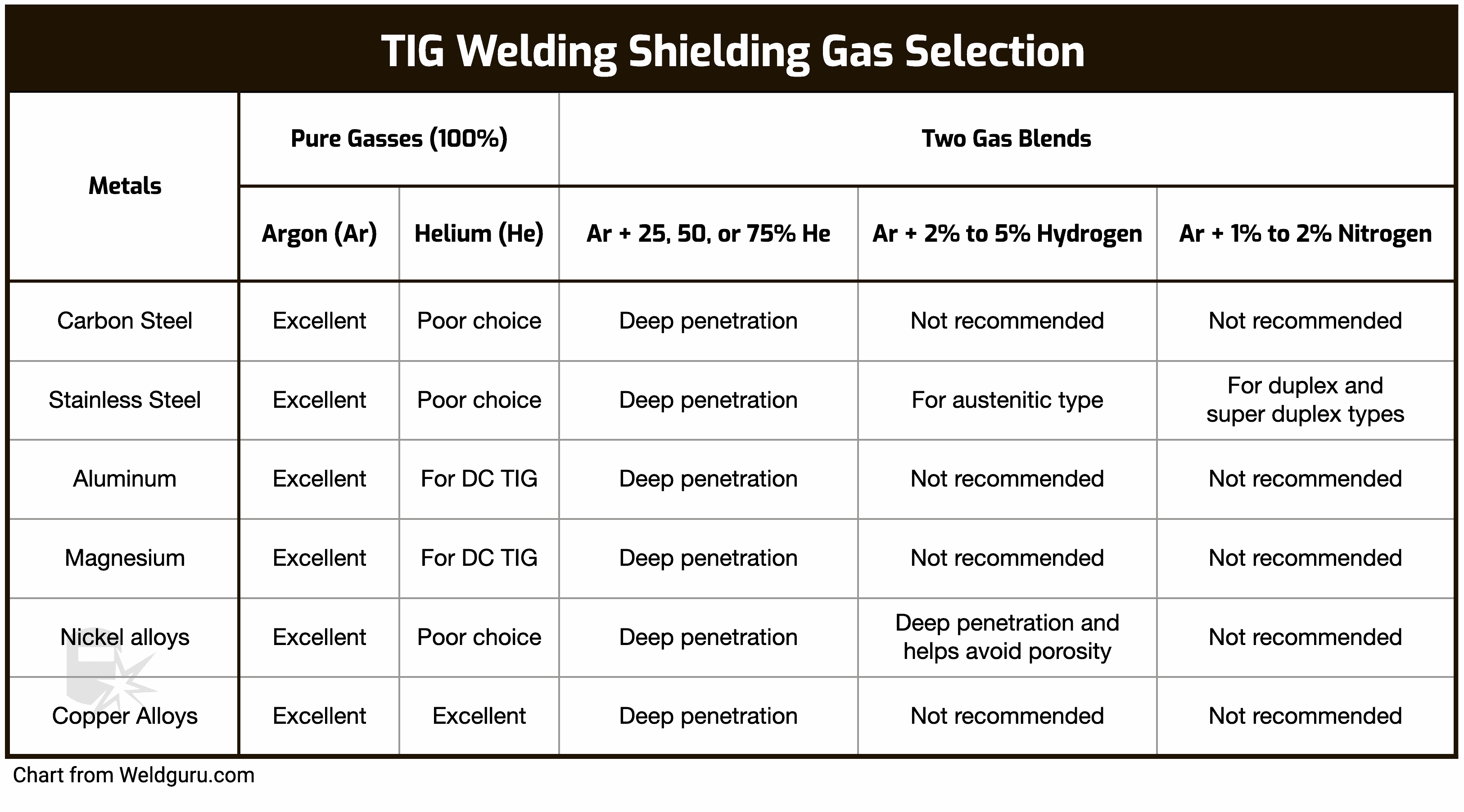

- Helium: Helium is like Argon's energetic cousin. It's also inert, but it's much hotter. While Helium *can* be used for TIG welding aluminum, especially on thicker pieces that need more heat input, it’s usually mixed with Argon. Using pure Helium can make things a bit… spicy. Think trying to grill a marshmallow with a flamethrower. Possible? Yes. Recommended? Probably not for beginners.

- Carbon Dioxide (CO2): This one's a big no-no. CO2 is like the mischievous gremlin of welding gases. It *loves* to react with things, especially at high temperatures. Using CO2 with aluminum would be like inviting that gremlin to a pool party with your weld. You'll end up with a corroded, porous mess. Steer clear!

- Oxygen: Another reactive gas that should be avoided like the plague. Imagine adding oxygen to a bonfire – it gets hotter and more reactive, right? Same thing happens with your weld. You'll end up with a nasty, oxidized weld that's weak and brittle.

Argon: Your Best Bet (Usually)

So, unless you're a seasoned pro experimenting with exotic gas mixtures (and if you are, you probably don't need my advice!), stick with Argon for TIG welding aluminum. It's readily available, relatively inexpensive, and provides excellent shielding, resulting in clean, strong welds. Think of it as the little black dress of welding gases – always appropriate, always stylish, and always gets the job done.

A Few Extra Tips

"Remember to use a dedicated aluminum spool gun or push-pull system if you're using a MIG welder for aluminum. And always, always clean your aluminum before welding. Even a little bit of dirt or oxide can ruin your day!"

Here's a few extra nuggets of wisdom to help you on your aluminum-welding journey:

- Gas Lens: Consider using a gas lens on your TIG torch. This helps to provide a more focused and consistent shielding gas coverage, leading to even cleaner welds. It's like upgrading from a garden hose to a precision watering system for your weld pool.

- Gas Flow Rate: Adjust your gas flow rate according to the size of your torch nozzle and the welding parameters. Too little gas, and you'll get oxidation. Too much gas, and you'll waste money and create turbulence. Finding the sweet spot is key.

- Cleanliness is Key: Aluminum is notorious for its oxide layer, which can contaminate your welds. Always clean the welding area thoroughly with a stainless steel brush and a dedicated aluminum cleaner before you start welding. Think of it as giving your aluminum a spa day before its big performance.

So there you have it! The lowdown on gas for TIG welding aluminum. Stick with Argon, keep your metal clean, and remember to have fun! Welding aluminum can be a challenging but rewarding experience. Now go forth and create some beautiful, molten masterpieces! You got this!