Ever watched a skilled welder effortlessly join pieces of aluminum and thought, "Wow, that looks cool!"? Welding aluminum with MIG (Metal Inert Gas) is a fantastic skill to learn, opening doors to countless DIY projects. Whether you're fixing a broken lawnmower deck, fabricating custom brackets for your car, or even creating artistic sculptures, knowing the right gas to use is absolutely crucial. It's like having the secret ingredient to a delicious recipe – without it, things just won't turn out right! And trust us, selecting the correct gas is way easier than you think.

So, what's the big deal about gas in MIG welding anyway? Well, the gas creates a protective shield around the weld, preventing atmospheric contaminants (like oxygen and nitrogen) from messing with the molten aluminum. Without this shield, your welds would be porous, weak, and generally ugly. For beginners, mastering this aspect of MIG welding aluminum is the first step towards achieving strong, reliable joints. Families who enjoy tackling home repairs together will find the right gas makes all the difference in creating lasting solutions. And for dedicated hobbyists, understanding gas selection unlocks a whole new level of creativity and precision in their projects.

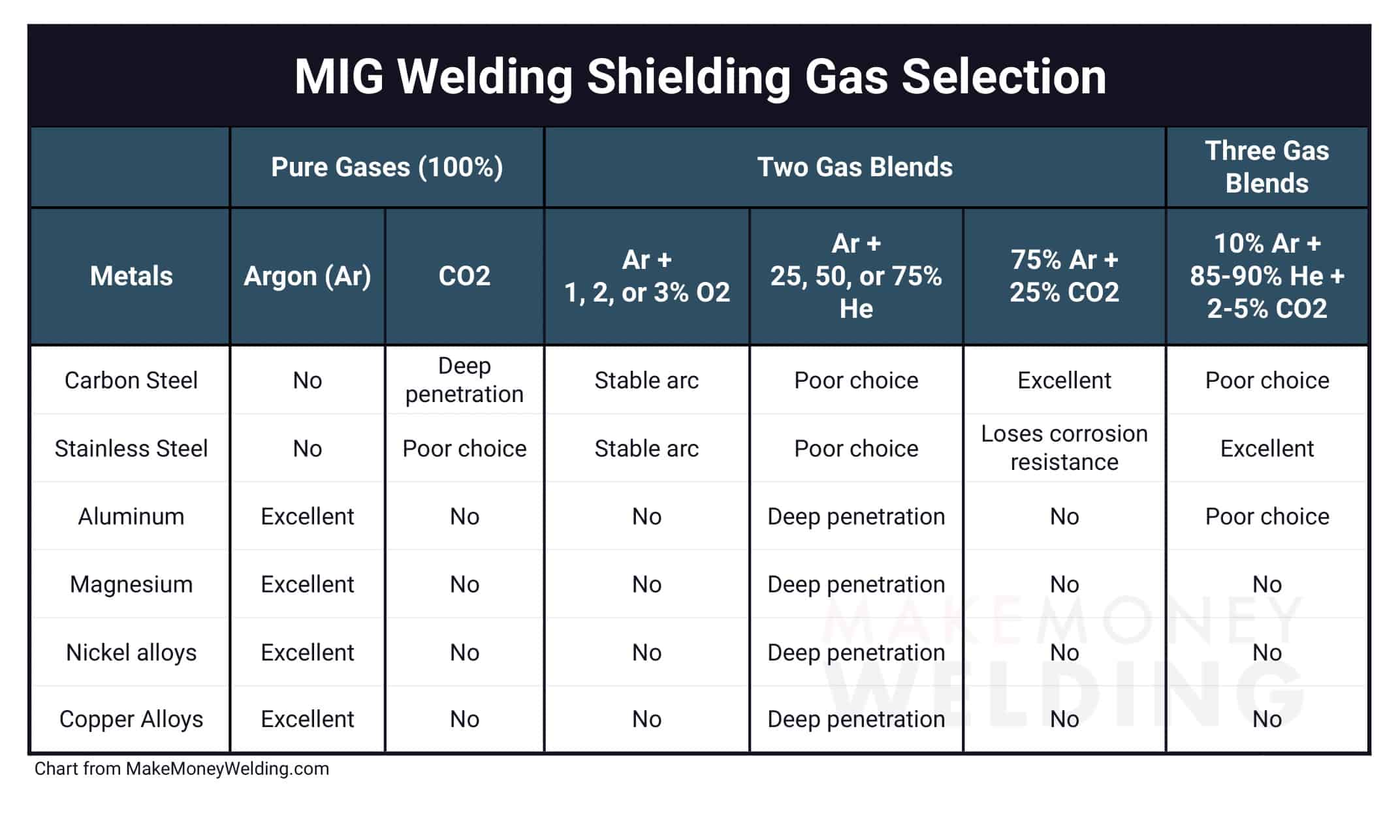

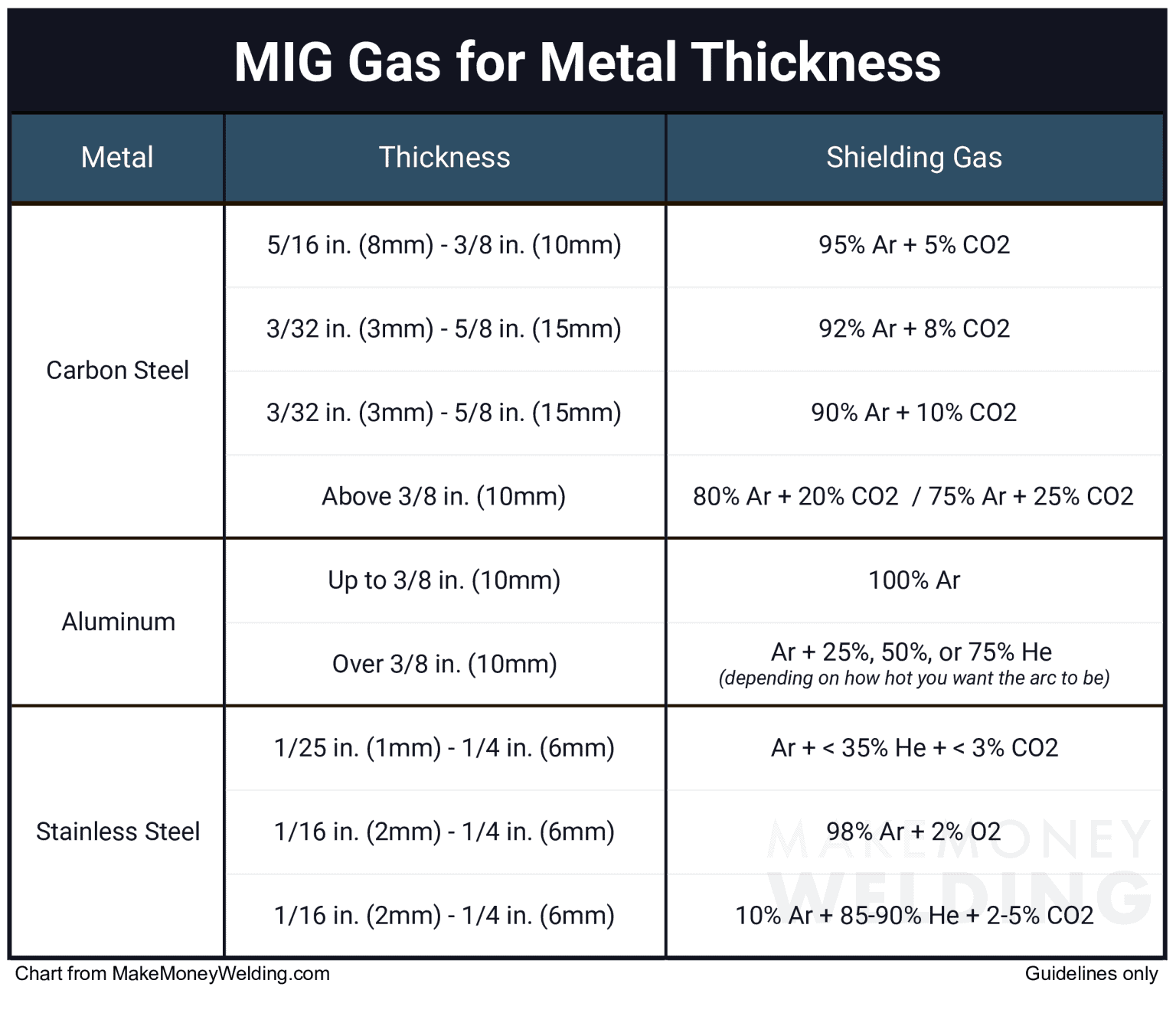

The go-to gas for MIG welding aluminum is almost always argon. It's readily available, relatively inexpensive, and provides excellent weld quality. Argon creates a stable arc and helps prevent the formation of aluminum oxide, a nasty substance that can weaken the weld. Think of argon as the reliable workhorse of aluminum welding.

While argon is the main star, sometimes you might encounter mixes. A common alternative is an argon/helium mix. Adding helium can increase the heat input, allowing you to weld thicker aluminum or increase travel speed. However, helium mixtures are more expensive and can make the arc a bit more difficult to control, especially for beginners. Generally, for most home and hobby projects, sticking with 100% argon is the safest and most cost-effective bet.

Here are a few simple, practical tips to get you started:

- Read your welding machine's manual. It will likely have recommendations for gas flow rates for different materials and thicknesses.

- Use a proper gas regulator and flow meter. This ensures a consistent and accurate gas flow.

- Start with a slightly higher gas flow rate than you think you need, and then adjust down. Too little gas is much worse than too much.

- Make sure your work area is well-ventilated. Welding fumes can be harmful, so good ventilation is essential.

- Practice, practice, practice! Welding takes time and experience to master. Don't be discouraged if your first few welds aren't perfect.

Choosing the right gas for MIG welding aluminum might seem daunting at first, but it's actually quite straightforward. Argon is your friend! By understanding the basics and following a few simple guidelines, you'll be creating strong, beautiful aluminum welds in no time. So grab your welding machine, your argon tank, and get ready to unlock a whole new world of creative possibilities! The satisfaction of fixing something yourself, or creating something new from scratch, is truly rewarding.