Let's talk about rescuing the seemingly un-rescuable! Ever had a beautiful antique cast iron skillet crack? Or maybe a vital part on your vintage tractor bite the dust? Instead of relegating these treasures to the scrap heap, you can learn to wield the magic of welding cast iron, specifically with nickel rods. It’s a skill that’s both incredibly useful and, dare I say, kind of fun! Imagine bringing a piece back to life, stronger and more beautiful than before. That's the power we're unlocking today.

So, what's the big deal with welding cast iron and why are nickel rods so important? Cast iron, for all its ruggedness, is a bit of a diva when it comes to welding. It's brittle and prone to cracking due to the rapid heating and cooling that traditional welding involves. This is where nickel rods enter the stage. They act as a more flexible intermediary, accommodating the cast iron's finicky nature and allowing you to create a strong, lasting bond.

The purpose of using nickel rods for cast iron welding boils down to a few key benefits. First, they have a lower melting point than cast iron. This means less heat is transferred to the base metal, reducing the risk of cracking. Think of it like a gentle massage versus a jarring jolt – the massage is far less likely to cause damage! Second, nickel rods produce a weld that's more ductile, meaning it can bend and flex without breaking. This is crucial because cast iron structures often experience stress and vibration. A brittle weld would simply shatter under pressure.

Beyond simply fixing cracks, welding cast iron with nickel rods opens up a world of possibilities. You can repair broken engine blocks, restore antique machinery, fix vintage stoves, and even create artistic sculptures. The possibilities are limited only by your imagination! Think about that old cast iron garden bench that's been sitting in the shed, waiting for a second chance. With a little welding knowledge and some nickel rods, you could transform it into a stunning centerpiece for your garden.

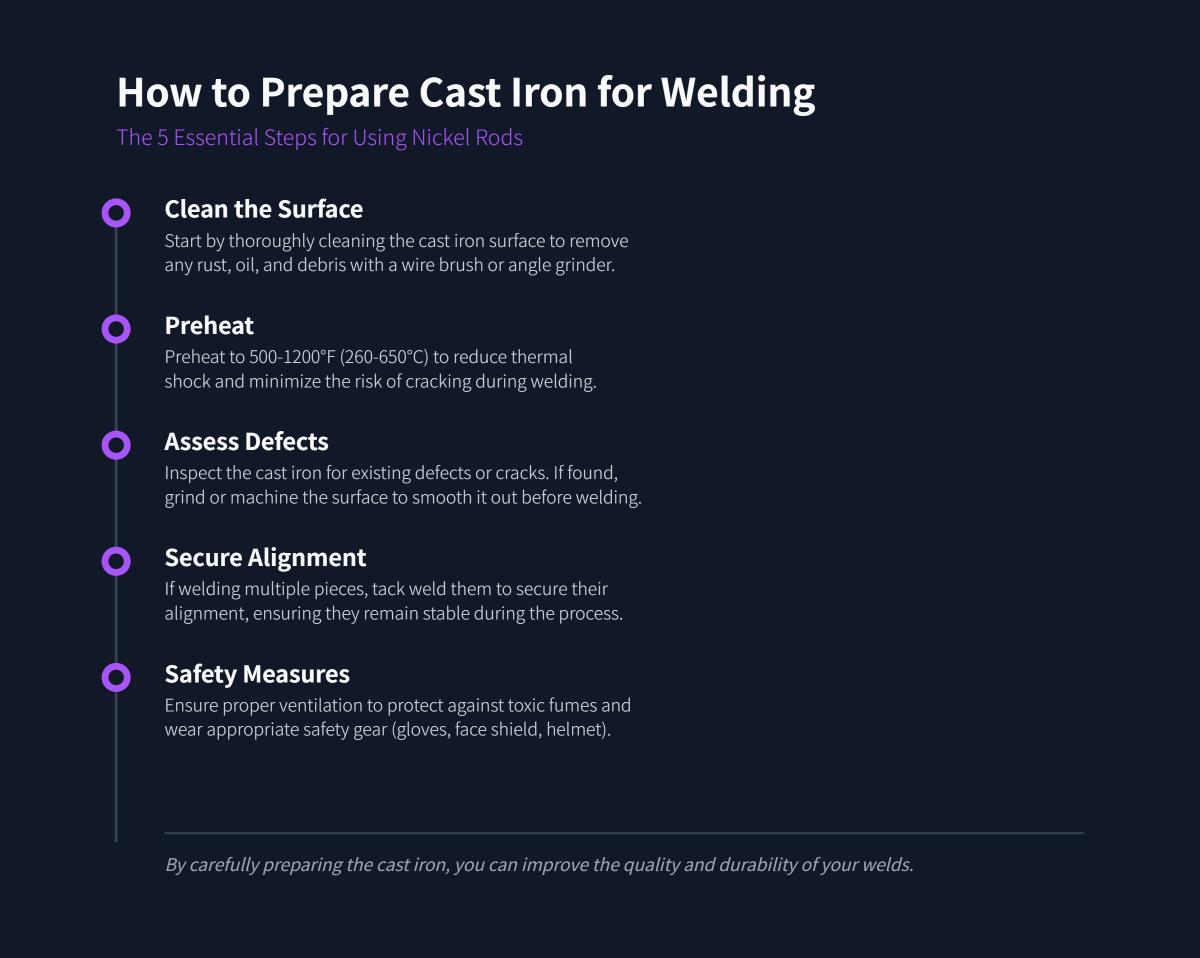

The process itself, while requiring some practice, isn't overly complicated. Preparation is key. You'll need to thoroughly clean the area to be welded, removing any rust, paint, or grease. Preheating the cast iron is also often recommended to further reduce the risk of cracking. Then, using a low amperage setting on your welder, you'll carefully apply the nickel rod in short, controlled bursts. Remember the "gentle massage" analogy? That applies here too! After welding, slow cooling is crucial to prevent stress buildup. You can bury the repaired piece in sand or wrap it in a welding blanket to achieve this.

Welding cast iron with nickel rods is a rewarding skill that allows you to breathe new life into old treasures. It's a combination of art and science, requiring patience and a bit of finesse. So, grab your welding helmet, some nickel rods, and get ready to unlock the potential hidden within that cracked cast iron! You might just surprise yourself with what you can accomplish, and you'll definitely impress your friends with your newfound ability to resurrect the seemingly broken.