Alright, gather 'round, folks! Let's talk about welding aluminum with an arc welder, or as I like to call it, "The Art of Not Blowing Holes Through Expensive Metal." Because trust me, that's a real skill you'll develop. Think of it as modern alchemy, except instead of turning lead into gold, you're turning perfectly good aluminum into… well, hopefully something structurally sound and not a molten puddle.

Now, before we dive in, a disclaimer: Welding aluminum with an arc welder (specifically, a stick welder – that dinosaur of the welding world) is like trying to herd cats on roller skates. It's possible, but it ain't pretty, and you'll probably end up with a few scratches – on the aluminum, and maybe on yourself.

The preferred method for aluminum is TIG or MIG, no question. But hey, maybe you're feeling adventurous. Maybe you've got an old stick welder gathering dust and a burning desire to weld aluminum just to prove you can. Or maybe you just lost a bet. Whatever the reason, I'm here to guide you through the perilous journey.

Why Aluminum is Such a Drama Queen

Aluminum is the Beyoncé of metals. Beautiful, lightweight, strong... and extremely temperamental. The main issue? It oxidizes faster than you can say "surface preparation." This oxide layer melts at a much higher temperature than the aluminum itself. So, you end up trying to melt the aluminum underneath while the oxide layer is stubbornly refusing to budge. This is why special aluminum electrodes (usually 4043 or 5356) are crucial. They’re designed to break through that stubborn oxide layer.

Think of it like trying to cook a steak with a layer of tin foil permanently stuck to it. Not ideal, right?

Gearing Up for Aluminum Armageddon

First things first, safety! This isn't just a suggestion; it's the law, and also common sense. You need:

- A good welding helmet. Preferably one that auto-darkens. Because nobody wants to accidentally flash themselves. Seriously, it's not a good look.

- Welding gloves. Because hot metal is hot. Duh.

- A welding jacket or apron. Protect your clothes! You don't want to explain those burn holes to your significant other.

- Safety glasses. Even under the helmet. Sparks are sneaky little devils.

- Closed-toe shoes. This isn’t a beach vacation.

Now, for the welding-specific stuff:

- An AC stick welder. AC is essential for aluminum welding with a stick welder. DC just doesn’t play nice.

- Aluminum electrodes. As mentioned earlier, 4043 or 5356 are your best bets. Make sure they’re specifically for stick welding, not TIG.

- A wire brush. For cleaning the aluminum. We'll get to that.

- Aluminum! Preferably some scrap pieces to practice on. Don't go experimenting on your prize-winning go-kart just yet.

The Aluminum Welding Tango: Preparation is Key

Before you even think about striking an arc, you need to clean the aluminum. And I mean really clean it. This isn't just a quick wipe with a paper towel. We're talking scrub-a-dub-dub with a wire brush until it shines like a freshly polished disco ball.

Why? Because that oxide layer is the enemy. Remove it! Brush vigorously, preferably right before you start welding, because it'll start oxidizing again almost immediately. It’s like painting your nails – looks great for about five minutes, then BAM! Chip city.

Also, beveling thicker pieces of aluminum helps to create a larger welding surface and allows for better penetration. Think of it as giving the weld more room to bond.

Striking a (Difficult) Arc

Alright, deep breaths. This is where things get tricky. Aluminum conducts heat like crazy, so you'll need to move fast. Like, cheetah-on-a-caffeine-binge fast.

Set your welder to the appropriate amperage. Start low and increase it until you get a stable arc without blowing holes. There's a sweet spot, and finding it is part of the fun (or frustration, depending on your perspective).

Use a quick, whipping or circular motion to deposit the weld. Don't linger too long in one spot, or you'll end up with a molten mess. Imagine you're a caffeinated mosquito flitting across the surface.

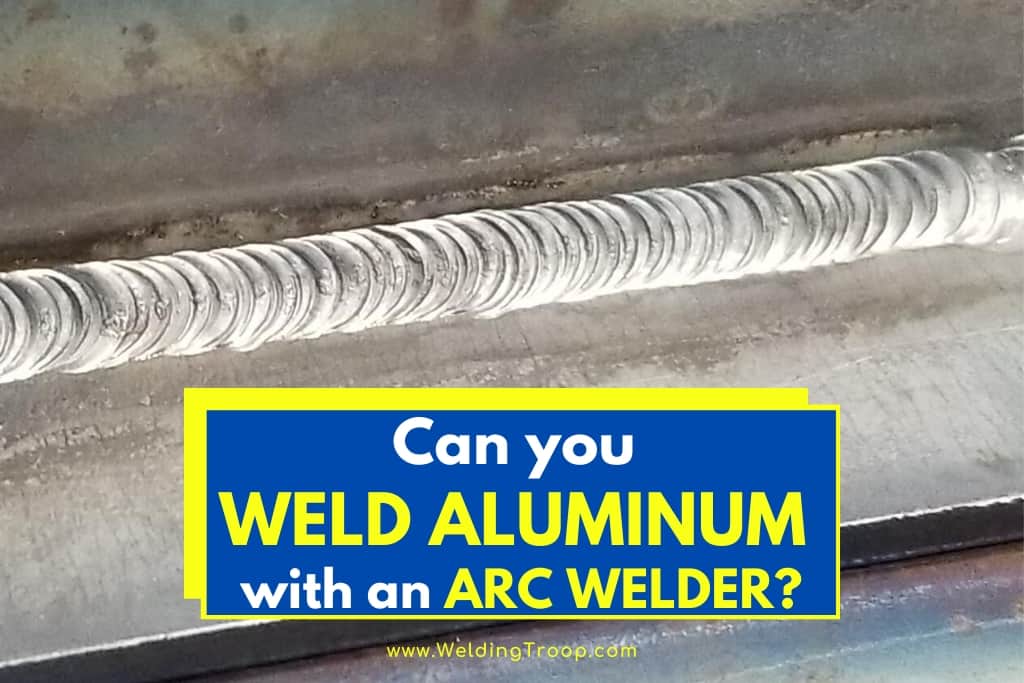

The key is to maintain a consistent arc length and travel speed. Easier said than done, I know. Practice, practice, practice! And don't be discouraged if your first few attempts look like a bird had a fight with a stapler. It happens to the best of us.

Troubleshooting Your Aluminum Fiasco

Porosity (lots of little bubbles): This usually means you're not cleaning the aluminum well enough, or you're welding too slow. Speed it up and scrub harder!

Burn-through (big holes): Too much amperage! Dial it down, Speedy Gonzales.

Arc instability: Could be a number of things. Make sure your ground clamp is securely attached, your electrodes are dry, and you haven't angered the welding gods in some way. Offering a sacrifice of pizza never hurts.

Slag inclusions: This is where bits of the electrode get trapped in the weld. Use proper technique and electrode angle to prevent this.

The Grand Finale: Admiring (or Cringing At) Your Handiwork

Once you're done welding, let the aluminum cool down. Don't quench it with water; that can cause warping. Just let it air dry. Then, take a good look at your weld.

Did you create a masterpiece of modern engineering? Or did you create a metal sculpture that looks like it was designed by a committee of drunk squirrels? Either way, you learned something. And that's what really matters… right?

Welding aluminum with a stick welder is challenging, but it's also rewarding. It's a testament to your skill and perseverance. And hey, if all else fails, you can always grind it down and pretend it never happened. Just don't tell anyone I told you that.