Let's talk about something exciting: squishing stuff! Specifically, metals. Think about bending a paperclip until it snaps. That, my friends, is where the True Stress and True Strain Curve comes in. Don't run away! It's less scary than filing taxes, I promise. (Okay, maybe that's a low bar.)

We all know stress. It's that feeling when your phone dies at 2% battery, right before you need GPS. In engineering, stress is force divided by area. Simple. Strain? That's how much something stretches or shrinks. Like your jeans after Thanksgiving dinner.

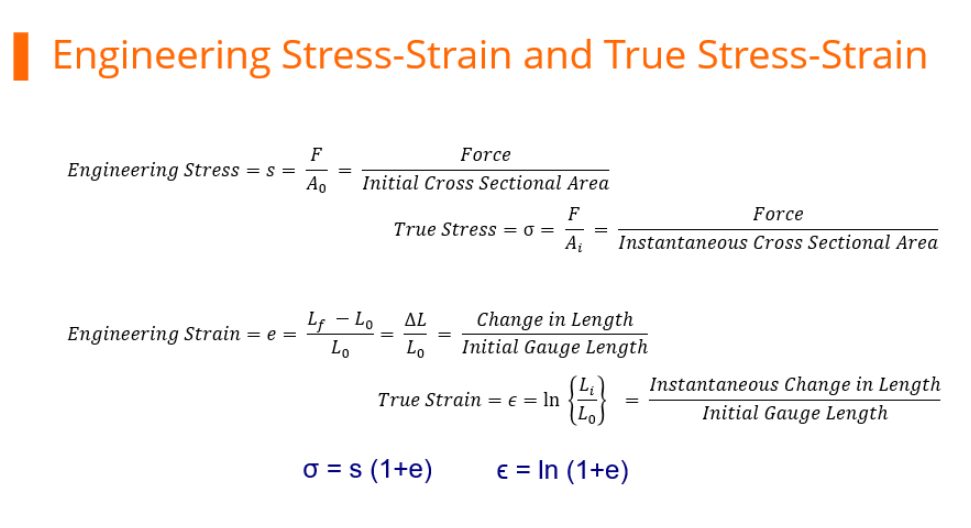

Now, for the "true" part. This is where things get... real. You see, regular "engineering" stress and strain use the original dimensions of the material. Which is a LIE! (Unpopular opinion alert!) The paperclip gets thinner as you bend it. The area changes! Ignoring that is like pretending your weight hasn't changed since high school. We all know that's not true.

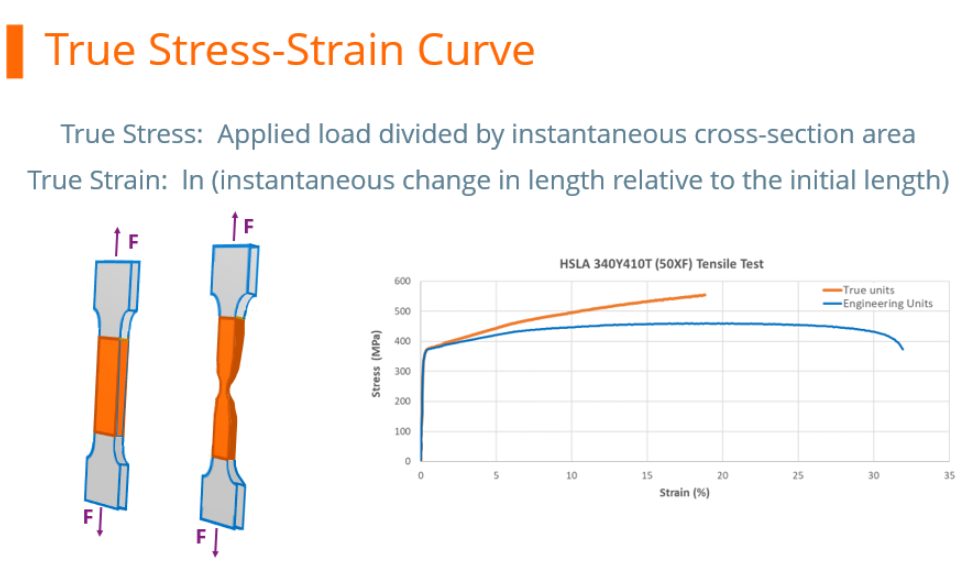

The True Stress and True Strain Curve accounts for this change. It’s like the honest friend who tells you the jeans *really* don't fit anymore. It uses the instantaneous area and length. So, it's a more accurate picture of what's actually happening inside the material as it deforms.

The Curve Itself: A Rollercoaster of Truth

Imagine a rollercoaster. That's kind of what the curve looks like. First, it goes up. This is the elastic region. Think of stretching a rubber band. Let it go, and it returns to its original shape. The material is just politely deforming.

Then, we reach the yield point. This is where the rubber band starts to stay stretched. Permanent damage! The material is saying, "Okay, you've convinced me to change." This is also where the *real* fun starts.

After yielding, the curve keeps climbing (usually). This is strain hardening. The material is getting stronger as you deform it. It’s like working out. Every bend makes it harder to bend further. It’s building up its resistance like you build up excuses for skipping the gym.

Eventually, the curve hits a peak: the ultimate tensile strength. This is the material’s “peak performance.” It's the strongest it will ever be. After this point, it starts to weaken. It’s like a celebrity after their peak; it's all downhill from there.

Finally, the curve plummets. This is the necking region. A small area starts to thin out rapidly. It’s like when you get a hole in your sock, and it quickly unravels. This leads to the dreaded fracture point: SNAP! The paperclip breaks. The end.

Why Should You Care? (Besides the Sheer Thrill)

Okay, so why is this "True Stress and True Strain" stuff useful? Well, it helps engineers design things that don't break easily. Bridges, airplanes, even paperclips. Knowing how materials behave under extreme conditions is crucial. No one wants a bridge collapsing because someone used the wrong kind of steel based on engineering stress values! (That would be a *very* unpopular opinion from the bridge designer.)

Plus, it gives a deeper understanding of the material’s properties. True Strain is particularly handy. If we really want to compare how ductile (how much it stretches) different metals really are, True Strain helps us because it takes account of the increasing changes in the material cross section.

So, next time you're bending a paperclip (or just feeling stressed!), remember the True Stress and True Strain Curve. It's a testament to the fact that reality is often more complicated (and interesting) than we initially think. And that sometimes, the "true" story is the one worth knowing.

Now, go forth and squish things! (Responsibly, of course.)

"Engineering stress is an absolute fabrication!" – Said no one... until now? ;)