Okay, picture this: you're in your garage, maybe humming along to some 80s power ballad. You’ve got your gloves on, your helmet down, and a serious mission in mind.

It's time to wrestle with aluminum, that shiny, stubborn metal, using the magical power of TIG welding.

The Tungsten Tango

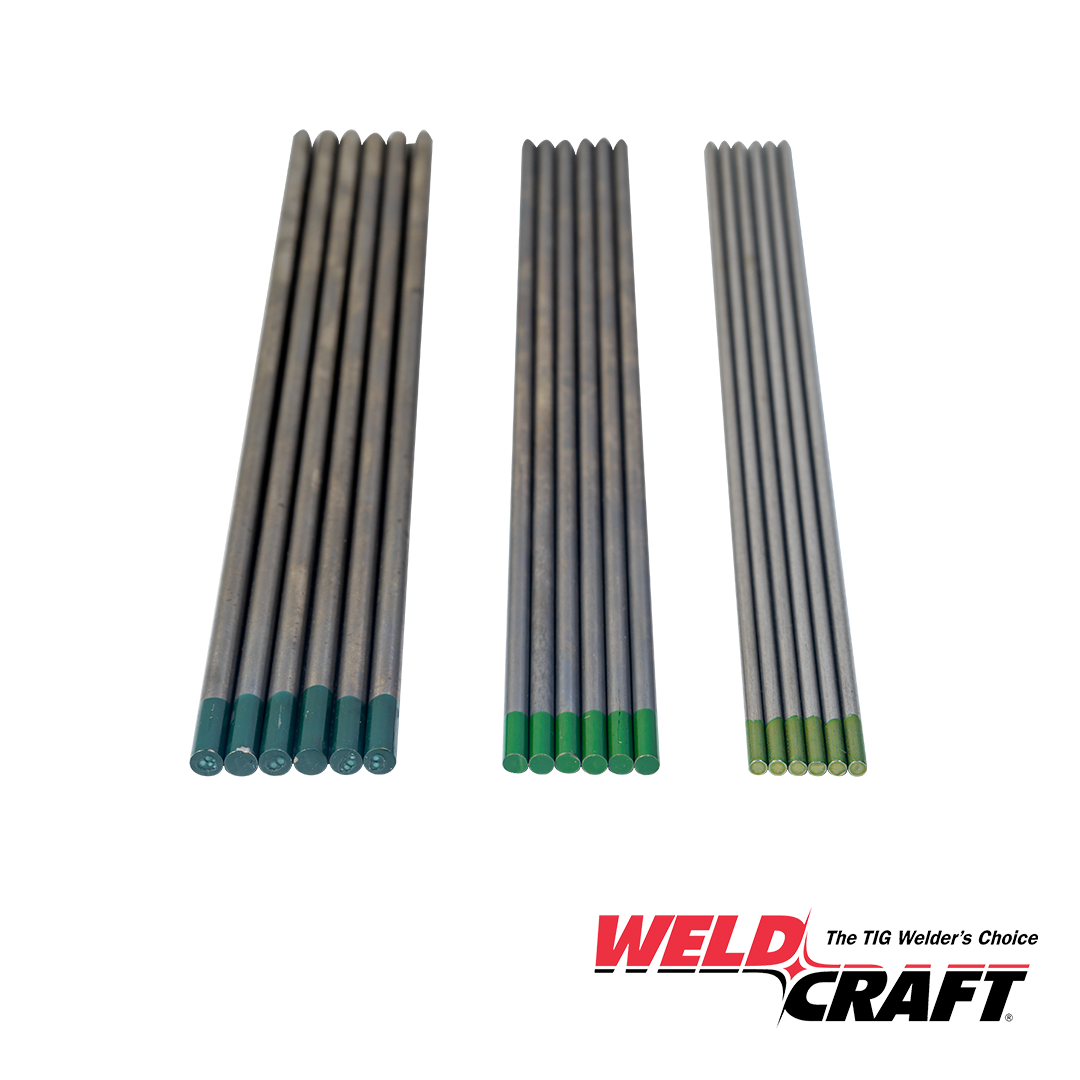

Now, let's talk about tungsten. It sounds like something from a sci-fi movie, right? But it's really just a metal that can withstand a crazy amount of heat, which makes it perfect for TIG welding.

Think of the tungsten electrode as your conductor, the maestro of the welding orchestra. It’s not going to be consumed, but it conducts electricity like a boss, creating the arc that melts the metal. This arc is where the magic happens!

Choosing the right tungsten is like picking the perfect dance partner. Get it wrong, and you'll be tripping over your own feet. Get it right, and you'll be gliding across the metal like Fred Astaire.

Pointy vs. Ball-shaped: A Question of Style

Here's a little secret: for aluminum TIG welding, you don't want a super pointy tungsten. A slightly balled or rounded tip is the way to go.

Why? Because a balled tip creates a more stable arc on aluminum. It's less likely to wander around like a lost puppy.

Imagine trying to write your name with a pencil that keeps changing its point size. Frustrating, right? Same deal with the tungsten tip.

The Aluminum Allure

Aluminum is a quirky metal. It's lightweight, strong, and doesn't rust. But it’s also got a few tricks up its sleeve.

One of those tricks is its tendency to form an oxide layer on its surface. This layer is like a stubborn force field that prevents the weld from properly joining the pieces.

To defeat this layer, TIG welding for aluminum uses alternating current (AC). It is sort of like using a jackhammer on that oxide layer.

AC: The Key to Aluminum Harmony

AC current works by alternating the flow of electricity. This alternating flow creates a cleaning action that blasts away the oxide layer. Think of it like a tiny welding Jedi using the Force.

Without AC, you're basically trying to weld through a layer of rust. Not pretty. With AC, you get a clean, strong weld.

It's like the difference between trying to paint a wall without sanding it first and properly preparing the surface. The final result will be much better.

The Dance of the Torch

Now, for the actual welding. It's a bit like a dance. You've got your torch in one hand, your filler rod in the other, and you're moving in sync to create a beautiful weld.

The torch provides the heat, melting the aluminum and creating a molten puddle. The filler rod adds extra metal to fill in the gaps and strengthen the weld.

It takes practice to get the rhythm right. Too much heat, and you'll burn through the aluminum. Too little heat, and the weld won't penetrate properly.

Patience, Young Padawan

Don't get discouraged if your first few welds look like abstract art. TIG welding takes time and patience to master.

The best way to learn is to practice, practice, practice. Find some scrap aluminum and start experimenting. Try different settings, different tungsten types, and different techniques.

Watch videos, read articles, and ask for advice from experienced welders. It can be like learning a new language, but stick with it.

The Zen of Welding

There's something almost meditative about TIG welding. The focus, the precision, the quiet hum of the machine... it can be surprisingly relaxing.

It's a chance to escape the stresses of everyday life and focus on a single, tangible goal. To create something beautiful and functional with your own hands.

Okay, maybe that's a little too romantic. But there's definitely a sense of satisfaction that comes from laying down a perfect bead of weld.

The Unexpected Beauty

And let's be honest, a good weld can be a thing of beauty. The ripples, the color, the perfect fusion of metal... it's like a tiny work of art.

You might even find yourself admiring your welds, showing them off to your friends, and posting pictures on social media. Don't worry, it's normal.

It means you've caught the TIG welding bug. And there are worse things to catch.

Humorous Mishaps

Now, I would be remiss if I didn’t mention the funny bits, the times where everything goes wrong, and you're left staring at a melted, smoking mess of aluminum.

Like the time you accidentally welded your glove to the workbench. Or when the shielding gas ran out mid-weld, creating a shower of sparks and a very unhappy sound.

Or that time you were so focused on your weld that you didn't realize your pants were on fire. Okay, maybe that's just me.

Laugh it Off

The important thing is to laugh at your mistakes and learn from them. Welding is a skill, and like any skill, it takes time and effort to develop.

Don't be afraid to experiment, to try new things, and to make mistakes. It's all part of the process.

And remember, even the most experienced welders have their bad days. They just don't talk about them as much.

Heartwarming Creations

Beyond the technical aspects, TIG welding opens up a world of creative possibilities. You can build custom furniture, repair broken equipment, or create unique works of art.

There's something incredibly satisfying about fixing something that's broken, about giving new life to an old object.

You could craft a beautiful aluminum sculpture, a sturdy bike rack, or a custom part for your vintage car. The sky's the limit.

The Gift of Making

And perhaps the most rewarding aspect of TIG welding is the ability to create things for others. To build a gate for your neighbor, to repair a wheelchair for a friend, or to create a special gift for a loved one.

These are the moments that make all the frustration and the learning curve worthwhile. These are the moments that turn welding from a skill into a passion.

So, go forth and weld! Embrace the challenges, celebrate the successes, and never stop learning. You might just surprise yourself with what you're capable of creating.

Who knows, maybe you'll be the next welding superstar. Or maybe you'll just have a really cool hobby. Either way, it's a journey worth taking.

Just remember to wear your safety glasses, and maybe keep a fire extinguisher handy.