Okay, let's talk TIG welding. Sounds intimidating, right? Like something out of a sci-fi movie. But trust me, even if you're more familiar with a spatula than a welding torch, understanding a little about filler rod can seriously up your DIY game. Think of it like this: you're baking a cake (stay with me!). The welding machine is your oven, the metal you're joining are your ingredients, and the filler rod? That's the extra flour or sugar you need to get everything just right. Specifically, we're diving into filler rod for mild steel.

Why Bother With Filler Rod?

Why can't you just melt the two pieces of metal together without adding anything? Well, sometimes you can! But most times, you'll end up with a weaker weld. Imagine trying to glue two pieces of wood together without any glue. Sure, they *might* stick for a little while, but a good knock will probably break them apart. Filler rod acts like that super-strength glue, adding extra material to the weld pool, making it stronger and more durable. It fills in any gaps, compensates for metal lost during the welding process, and helps control the weld's shape and appearance.

Think of it like patching a hole in your jeans. You could just try to sew the edges together, but you'd likely end up with a weak, puckered mess. Adding a patch (the filler rod equivalent) gives you extra material to work with, creating a stronger, smoother repair. It's the same principle with welding!

Choosing the Right Filler Rod: Like Goldilocks, Finding What's "Just Right"

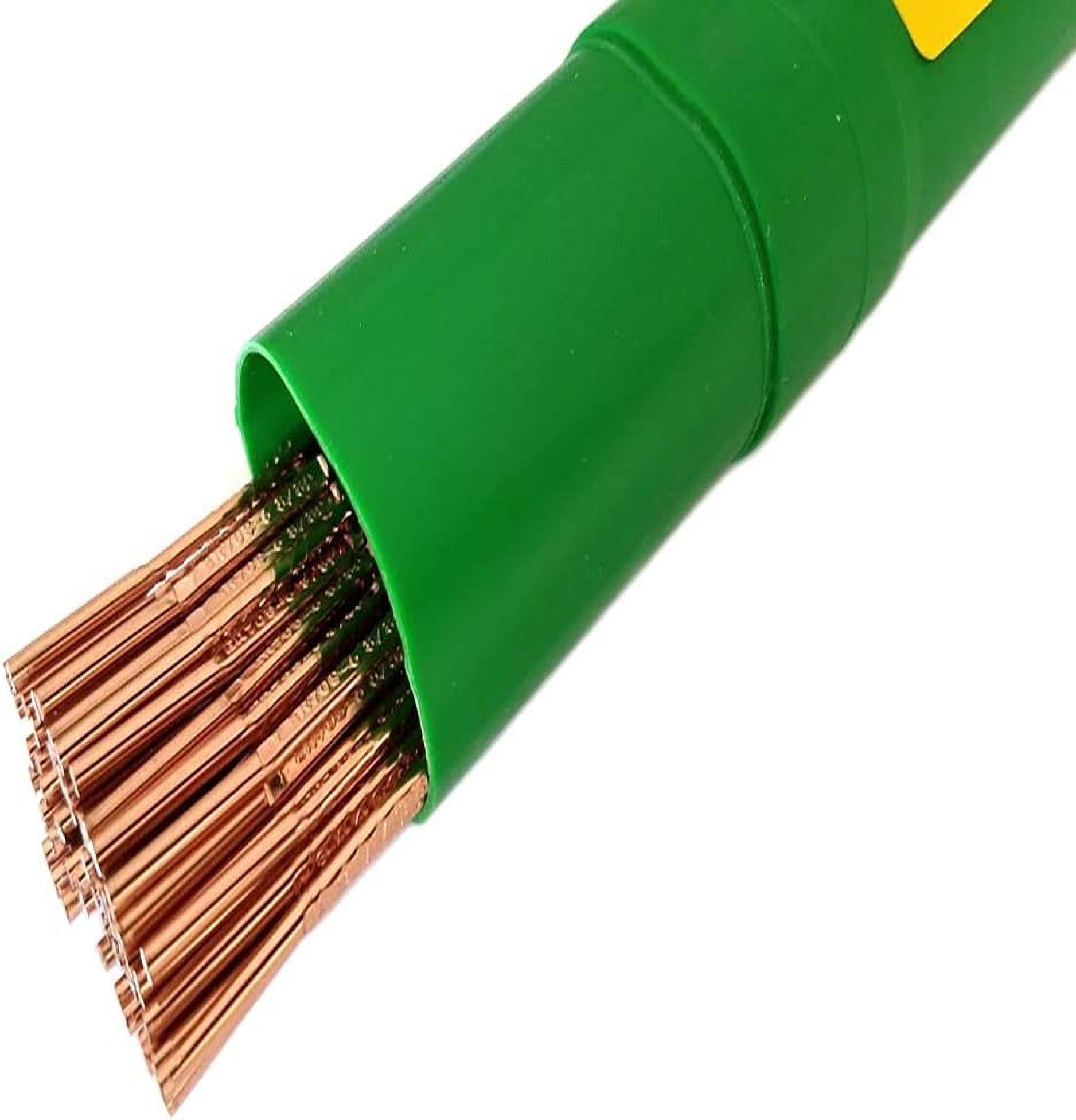

So, you're convinced you need filler rod. Great! But now you're faced with a wall of different types. Don't panic. For mild steel, you'll generally be looking at rods labeled ER70S-2 or ER70S-6. These are your workhorses, reliable and readily available.

The "ER" stands for "Electric Rod." The "70" indicates a tensile strength of 70,000 pounds per square inch (PSI). In plain English, that means it's pretty strong! The "S" signifies that it's a solid wire. And the number after the dash? That refers to the deoxidizers in the rod. Deoxidizers are like little scavengers that clean up the weld pool, preventing porosity (tiny holes that weaken the weld). ER70S-6 has more deoxidizers than ER70S-2, making it a bit more forgiving on dirtier or rustier metal.

Think of ER70S-2 like a fine wine – it prefers a clean palate. It's excellent for clean, new steel and produces beautiful, shiny welds. ER70S-6, on the other hand, is like a hearty stew – it can handle a bit more roughness and still deliver a satisfying result. If you're welding something that's been sitting in the garage for a while, ER70S-6 is usually a safer bet.

Bottom line: For most DIY projects with mild steel, ER70S-6 is your go-to filler rod.

The Right Size Matters: No Tiny Rods for Big Jobs

Just like using the right size paintbrush for a wall, you need to choose the appropriate diameter filler rod. Too thin, and you'll be feeding it in constantly, struggling to fill the weld joint. Too thick, and you'll be overheating the metal, creating a messy, uncontrolled weld.

For most hobbyist TIG welders working with common thicknesses of mild steel (think 1/8" to 1/4"), a 1/16" or 3/32" diameter filler rod is a good starting point. Experiment and see what feels comfortable. It's like finding the perfect size spoon for your soup – it's a matter of personal preference and the size of your bowl (or, in this case, the weld joint!).

Feeding the Beast: Technique Tips for TIG Welding with Filler

Okay, you've got the right rod. Now what? The key is smooth, consistent feeding. Dip the filler rod into the leading edge of the weld pool, allowing it to melt and fuse with the base metal. Think of it like gently stirring cream into your coffee – you want a smooth, even blend.

Avoid jabbing or poking the rod into the weld pool. This can create inclusions (bits of unmelted rod trapped in the weld) and weaken the joint. Aim for a rhythmic dipping motion, maintaining a consistent arc length and travel speed. Practice makes perfect, so don't be discouraged if your first few welds aren't masterpieces. We've all been there! Even Michelangelo started with stick figures (probably…).

Remember, safety first! Wear your welding helmet, gloves, and appropriate clothing. TIG welding produces intense UV radiation, so protect your skin and eyes. And always weld in a well-ventilated area.

Beyond the Basics: The Joy of Welding

Choosing the right filler rod for TIG welding mild steel isn't rocket science, but it's a fundamental skill that can significantly improve the quality and strength of your welds. By understanding the different types of filler rods, choosing the right size, and practicing your technique, you'll be well on your way to creating beautiful, durable welds that will last a lifetime. So go forth, grab your TIG torch, and start welding! And don't forget to have fun. Welding can be incredibly rewarding, allowing you to create, repair, and customize all sorts of things. Who knows, maybe you'll even build your own robot one day! (Okay, maybe that's a stretch. But you *could* fix that wobbly patio chair.)