Ever wondered what gives a samurai sword its legendary sharpness, or a chef's knife its unwavering precision? The answer, in part, lies in the fascinating process of tempering steel – a fiery dance of heating and cooling that transforms brittle metal into something incredibly strong and resilient. It's not just about blacksmiths and bladesmiths; the principles of tempering resonate far beyond the forge.

The Art of the Steel Makeover

Think of raw steel like a stressed-out millennial – full of potential, but prone to cracking under pressure. Untempered, it's hard, but too hard. It shatters instead of bending. Tempering is the steel's version of a wellness retreat, a carefully controlled process designed to relieve internal stresses and optimize its properties.

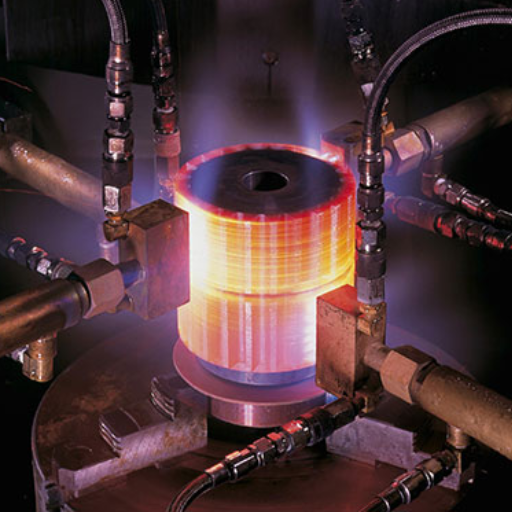

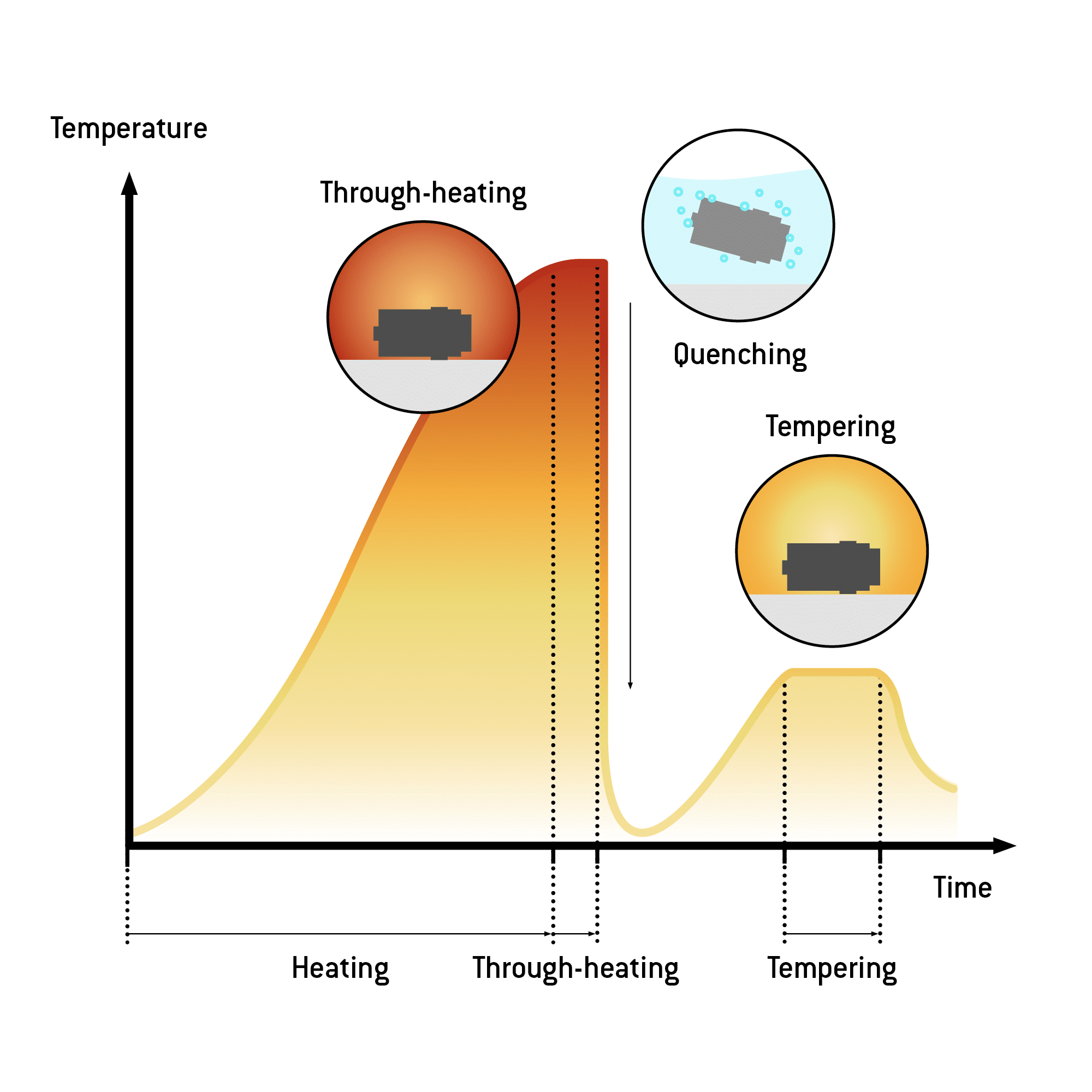

The process involves heating the hardened steel to a specific temperature, well below its melting point, and then allowing it to cool. This seemingly simple cycle brings about remarkable changes in the steel's microstructure, making it tougher and more ductile.

The Heat is On: Color-Coded Transformations

The temperature to which the steel is heated dictates the final properties. Traditionally, blacksmiths would judge the temperature by the color of the glowing steel. This is where things get beautifully analog. Imagine a spectrum:

- Straw Yellow: Around 400°F (200°C). Ideal for tools needing a very hard edge, like razors and scribes.

- Dark Straw/Gold: Approaching 450°F (230°C). Great for knives, axes, and punches.

- Purple/Brown: In the 500°F (260°C) range. Think springs and wood-cutting tools.

- Blue: Reaching upwards of 600°F (315°C). Used for screwdrivers and wrenches – tools where toughness is paramount.

Modern methods use more precise temperature monitoring, of course, but the core principle remains the same: precise control is key.

Cooling Down: From Fiery to Functional

After reaching the desired temperature, the steel is cooled. The cooling method also plays a crucial role. While quenching (rapid cooling in water or oil) is used during the initial hardening process, it's generally avoided during tempering, as it can reintroduce stress. Instead, air cooling is preferred, allowing the steel to gradually return to room temperature and stabilize.

Think of it like letting a fine wine breathe. A slow, deliberate process that allows the flavors (or, in this case, the material properties) to fully develop.

Practical Tips for the Modern Maker

While you might not be forging samurai swords in your backyard (though, kudos if you are!), understanding tempering can still be incredibly useful:

- Knife Care: Understanding hardness and toughness helps you choose the right knife for the job. A very hard knife might hold an edge longer but be more prone to chipping. A tougher knife might dull faster but withstand more abuse.

- Tool Maintenance: If you're sharpening tools, be careful not to overheat them. Overheating can draw the temper, making the edge brittle.

- DIY Projects: If you're working with metal in DIY projects, research the appropriate tempering techniques for the specific type of steel you're using. A little knowledge can go a long way.

Beyond the Blade: A Metaphor for Life

The process of tempering steel is more than just a technical procedure; it's a powerful metaphor. Just like steel, we all face intense pressures and fiery trials in life. These experiences can harden us, but without the right tempering – the careful cooling and reflection – we risk becoming brittle and prone to breaking.

Perhaps the key is to embrace the heat, learn from the experience, and then allow ourselves the time and space to cool down, to process, and to emerge stronger and more resilient. It’s about finding the balance between strength and flexibility, hardness and compassion. Like a perfectly tempered blade, we can then face whatever challenges come our way with unwavering resolve and a touch of grace.