Ever wondered what happens to a paperclip when you bend it back and forth until it snaps? Or why bridges don't collapse under the weight of cars? Well, that, my friends, is the secret world of materials, specifically, how mild steel behaves under pressure. And believe it or not, it's all beautifully illustrated by something called the Stress-Strain Graph. Think of it as the soap opera of metal, filled with tension, drama, and eventual heartbreak (for the metal, anyway!).

Imagine you’re stretching a rubber band. At first, it's easy, right? You pull a little, it stretches a little, and when you let go, it bounces right back to its original shape. That's kind of like the first part of the Stress-Strain Graph for mild steel, called the elastic region. "Stress," in this case, is how hard you're pulling, and "strain" is how much the steel is stretching. So, in the elastic region, the steel is like a well-behaved rubber band – stretch it, let go, and no harm, no foul. You can even imagine the steel politely apologizing for the temporary inconvenience.

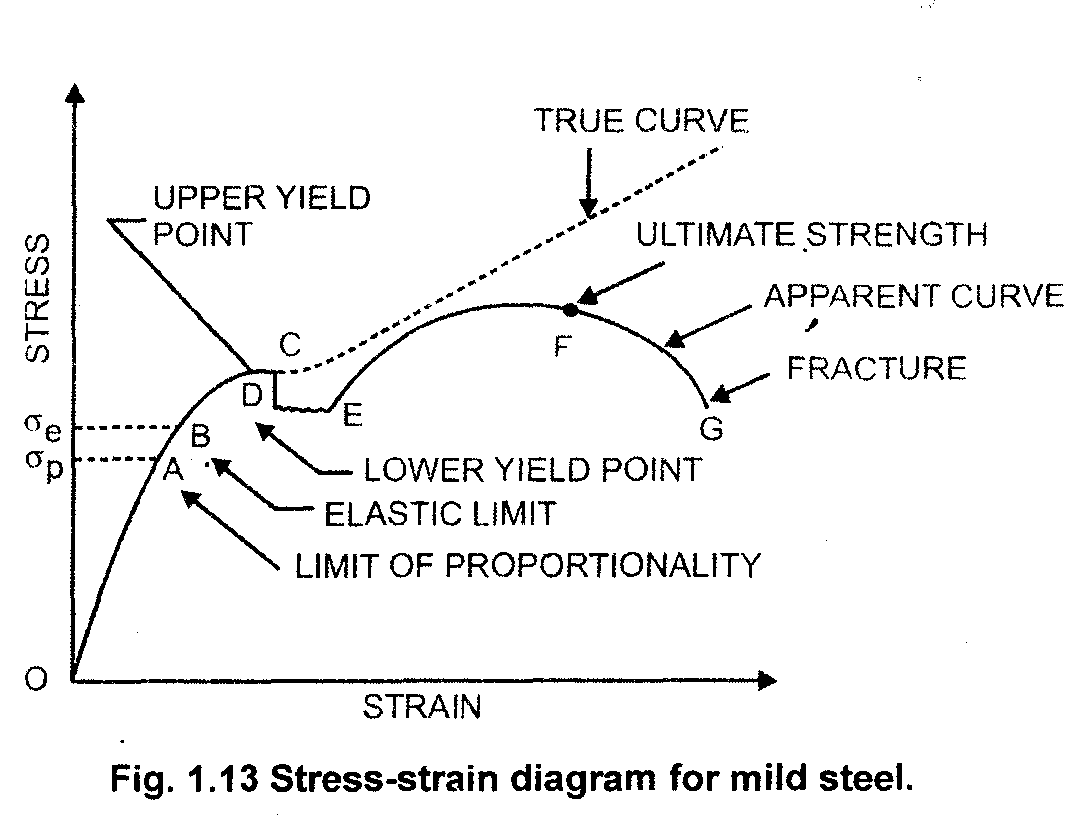

The Yield Point: Where Things Get Interesting

But keep stretching that rubber band, and eventually, you’ll reach a point where it starts to deform permanently. It won’t quite snap, but it won’t go back to its original shape either. This is the yield point. For mild steel, this is where things get really interesting. It's like that moment in a rom-com where the two characters finally realize they have feelings for each other! There is suddenly a drastic change. What makes mild steel somewhat unique is it displays both an "upper" and "lower" yield point. In the real world, its like deciding to go to the gym. You're all hyped to go (upper) then when you arrive you are tired (lower).

After the yield point, the steel enters the plastic region. Now, the steel is stretching more and more for the same amount of pull. It's started a journey down deformation road and there is no turning back! This is when the steel gets that "stretched-out" look and starts to lose its springiness. It’s like trying to fit into your skinny jeans after Thanksgiving dinner. It might work with a little extra effort, but they’ll never be quite the same again!

Strain Hardening: The Metal's Last Stand

Just when you think the steel is about to give up, it puts up one last fight! This is the strain hardening region. The steel actually gets stronger again as you continue to stretch it. It's like a marathon runner getting a second wind. But alas, it's a temporary reprieve.

Think about it: You're still pulling, still stretching. The steel is fighting back, but it's losing the battle. The stress required to stretch it further gets higher and higher.

Ultimate Tensile Strength and Fracture: The Grand Finale

Eventually, you reach the ultimate tensile strength. This is the point where the steel can't take it anymore. It's like that one last straw that breaks the camel's back. After this point, any further stretching leads to a rapid decrease in the amount of pull the metal can withstand. Necking, or localized plastic deformation, occurs. The stress starts concentrating at a single point, leading to the final act: fracture. The steel snaps! Our metal soap opera concludes with a dramatic, if somewhat abrupt, ending. Cue the sad music!

The Stress-Strain Graph isn’t just a boring chart in a textbook. It’s a visual representation of the metal's life story under stress. It's got its elastic moments of blissful resilience, its dramatic yield point where everything changes, its plastic period of unavoidable deformation, its heroic strain hardening, and its tragic final fracture.

So, the next time you see a bridge, a skyscraper, or even just a paperclip, remember the amazing, complex story hidden within the metal – a story told by the humble yet mighty Stress-Strain Graph. It's a heartwarming and humorous journey of resilience, adaptation, and, ultimately, the acceptance of its own limits. Now, that's a story worth bending an ear to, or, well, bending some steel!