Ever wondered how engineers ensure bridges don't collapse, or buildings don't crumble under heavy winds? A big part of the answer lies in understanding the properties of materials, especially steel, and how it behaves under stress. That's where the stress-strain curve comes in – it’s a fascinating and surprisingly useful tool that helps us predict how much punishment steel can take before it fails. Think of it as a material's breaking point, revealed in a graph!

So, what exactly *is* this stress-strain curve? In simple terms, it's a visual representation of how a material, like steel, responds when subjected to force. Stress is the force applied per unit area – imagine pulling on a steel rod. Strain is the deformation or change in length of the rod as a result of that force. The curve plots stress on the vertical axis and strain on the horizontal axis. As you increase the force, the curve traces out the steel’s response, revealing key properties like its elasticity, yield strength, and ultimate tensile strength.

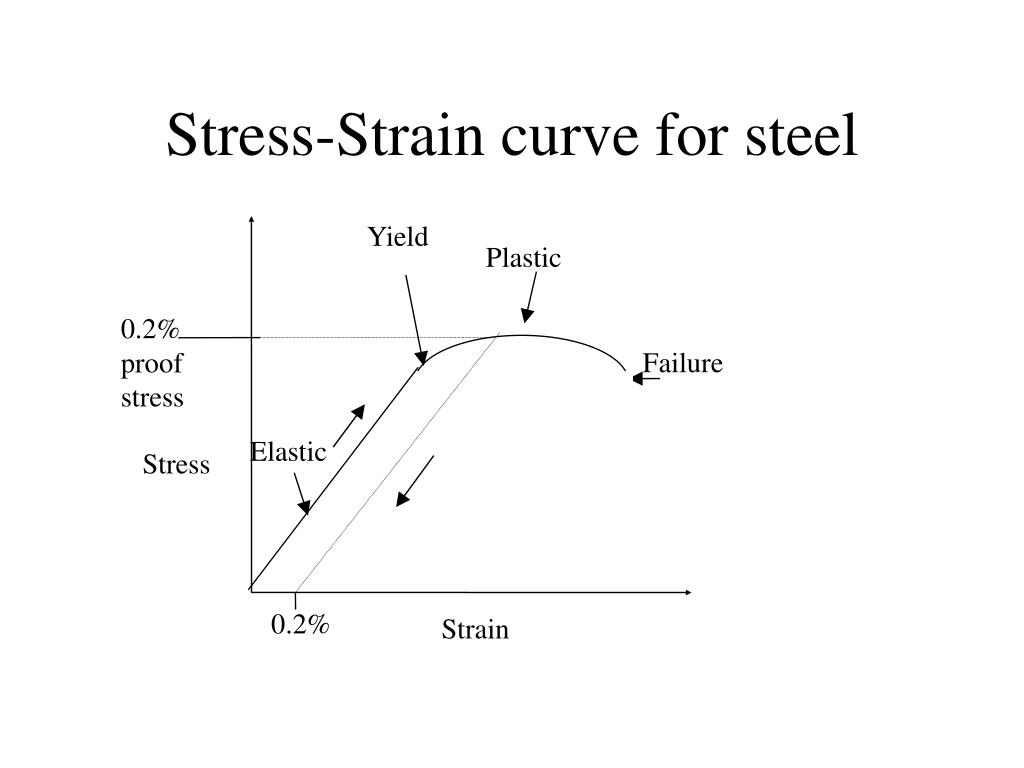

The beauty of the stress-strain curve is its ability to tell us a lot about a material at a glance. The initial, straight portion of the curve represents the elastic region. Within this region, the steel will return to its original shape when the force is removed – like stretching a rubber band. The point where the curve starts to bend is called the yield point. Beyond this point, the steel will experience permanent deformation, meaning it won't fully return to its original shape. Knowing the yield strength is crucial for engineers to ensure that structures don’t permanently deform under normal loads.

Further along the curve, we find the ultimate tensile strength (UTS). This represents the maximum stress the steel can withstand before it starts to neck down and eventually break. Finally, the curve ends at the fracture point, indicating the stress and strain at which the material breaks completely.

Understanding the stress-strain curve has numerous benefits. In engineering education, it's a fundamental concept for students learning about material science, structural analysis, and design. In daily life, engineers use this knowledge to design everything from bridges and buildings to car chassis and airplane wings. For example, when designing a skyscraper, engineers need to ensure that the steel used can withstand not only the weight of the building itself but also the forces of wind and earthquakes. The stress-strain curve helps them select the appropriate type of steel and determine the maximum load it can handle.

How can you explore this concept further? While conducting a real tensile test requires specialized equipment, there are many online simulations and interactive graphs that allow you to experiment with different types of steel and observe how their stress-strain curves differ. Search for "stress-strain curve simulation" or "tensile testing simulation." You can also explore the websites of material science departments at universities; many offer educational resources and animations. Even simply thinking about how different materials behave when you bend or stretch them – a plastic ruler versus a metal spoon, for example – can help you develop an intuitive understanding of stress and strain. The more you explore, the more you'll appreciate the hidden science behind the structures and objects that surround us every day!