Ever wondered why some things are tough as nails, while others bend like a wet noodle? A lot of it comes down to hardness. And when we talk about hardness, especially when talking about metal, one measurement that pops up a lot is "Rockwell C." Today, we're diving into the Rockwell C hardness of 1018 steel – a common, everyday workhorse of a material.

So, what *is* 1018 steel anyway? Imagine it as the "plain Jane" of the steel world. It’s not flashy, it’s not super exotic, but it's incredibly reliable and versatile. Think of it as that trusty old wrench in your toolbox, or the sturdy frame of your kid's bicycle. It’s everywhere!

What Does Rockwell C Even Mean?

Okay, let's break down "Rockwell C." It sounds intimidating, but it's just a way of measuring how well a material resists being dented. Think of it like this: imagine pressing your thumb into a stick of butter versus pressing your thumb into a rock. The butter is soft, the rock is… well, rock-hard. Rockwell C is a more precise, scientific way of measuring that resistance to indentation.

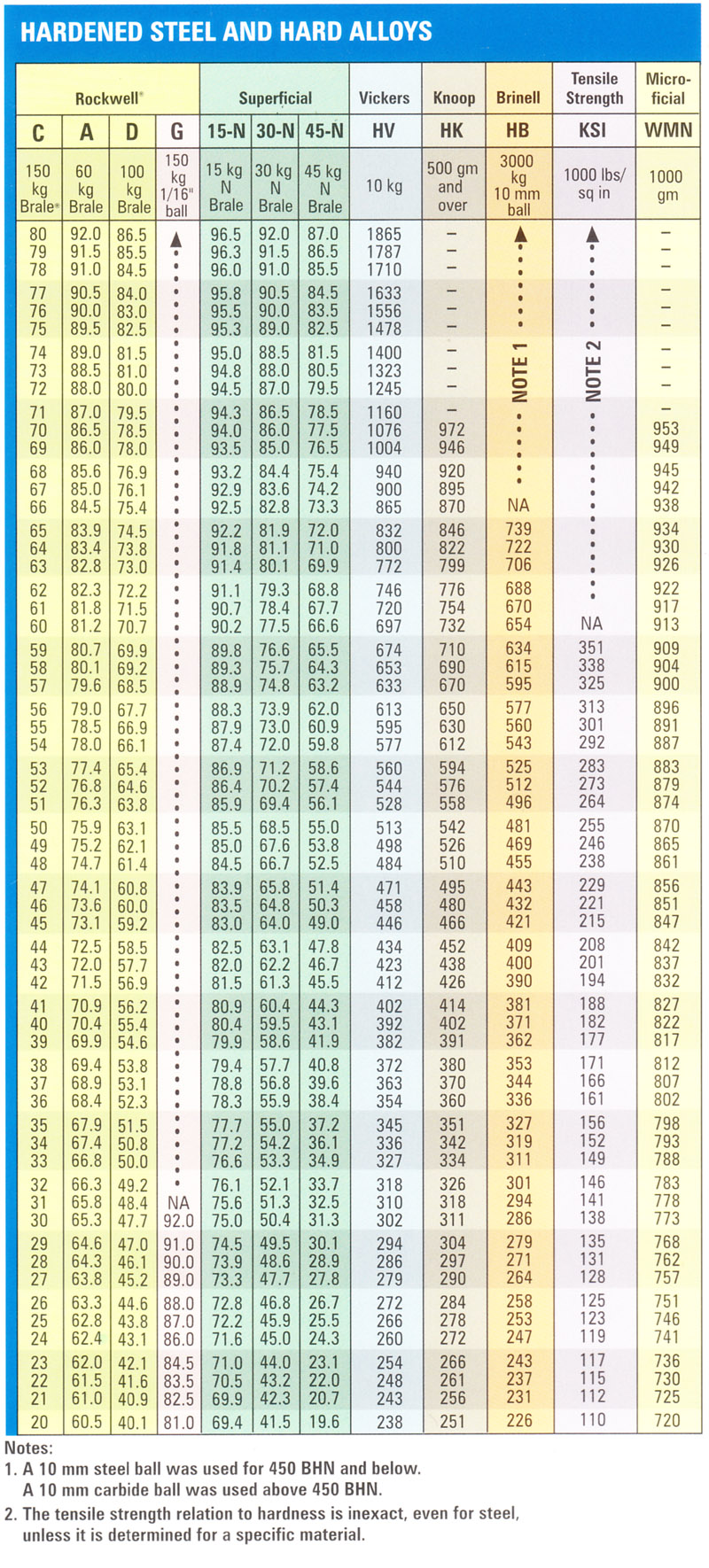

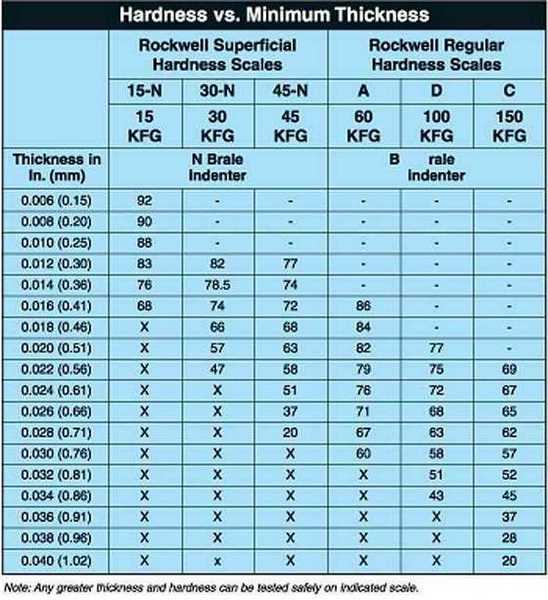

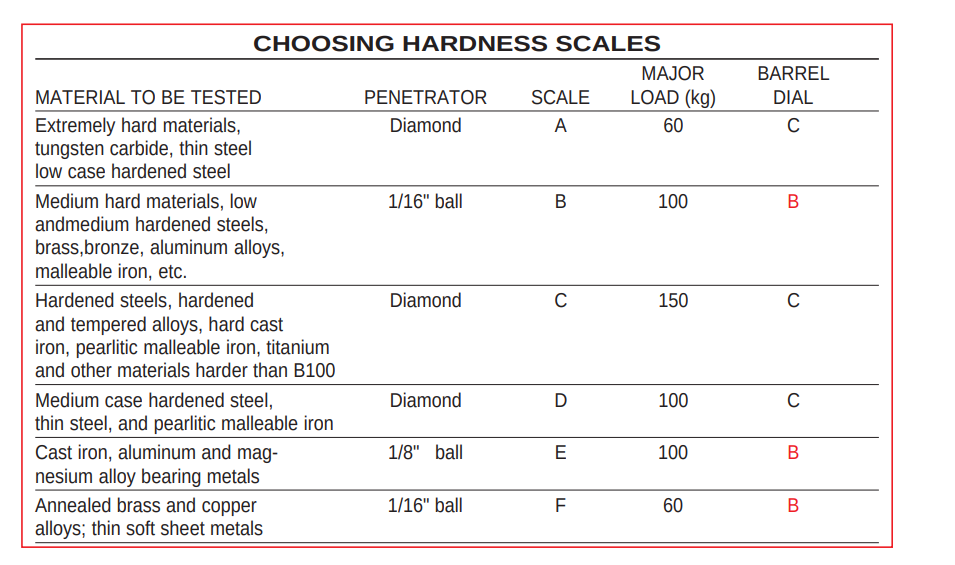

The "C" in Rockwell C refers to the specific type of indenter used in the test – a diamond cone. The machine measures how deep the indenter goes into the material under a certain load. Less indentation = higher Rockwell C number = harder material.

It's important to note that hardness isn't the same as strength. A material can be very hard and resist denting, but still be brittle and prone to shattering. Think of glass, which is hard but breaks easily. 1018 steel strikes a good balance of hardness and toughness.

1018 Steel: A Rockwell C Deep Dive

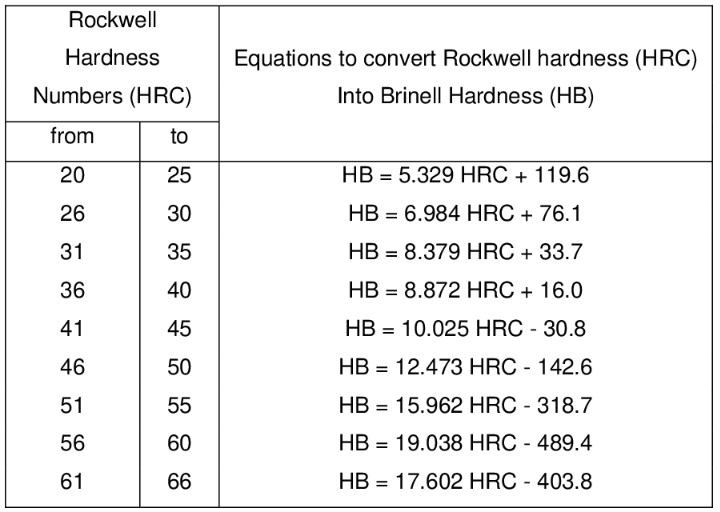

Now, onto the star of the show: 1018 steel. Typically, 1018 steel has a Rockwell C hardness somewhere in the ballpark of 15-25 HRC. Keep in mind that's a range, not a fixed number. The exact hardness can vary a bit depending on how the steel was manufactured and any heat treatments it might have undergone.

Why is that number important? Well, it tells us quite a bit about what 1018 steel is good for. That range of 15-25 HRC means it's relatively soft and easily machinable. Machinable means it can be easily cut, drilled, and shaped. It's like working with softwood compared to trying to carve granite. This makes it a favorite for parts that need to be precisely formed, like gears, shafts, and pins. It's also very weldable.

Why Should *You* Care?

Okay, so you're not a metallurgist. Why should you care about the Rockwell C hardness of 1018 steel? Because it helps you understand the qualities of things you use every day! Consider these examples:

- That bolt holding your bookshelf together? Chances are, it's made of something like 1018 steel. You want it to be strong enough to hold the weight but not so brittle that it snaps if you tighten it too much.

- The gears in a simple machine? 1018's machinability makes it perfect for cutting intricate gear teeth. The relatively low hardness means the gears wear out slower and can handle some abuse.

- The frame of some tools? Many hand tools use 1018 for parts because it can be shaped into various forms.

Understanding that 1018 steel is moderately hard and easily workable helps you appreciate the design choices behind everyday objects. It's not about memorizing a number, but about grasping the principle.

Heat Treatment: Turning Up the Dial

Here's where things get interesting. One of the cool things about steel is that its properties can be changed with heat treatment. Think of it like cooking. You can take the same ingredients (the steel), but by changing the temperature and cooking time, you get a completely different dish (different hardness and strength).

If you heat treat 1018 steel (specifically by hardening it), you can significantly increase its Rockwell C hardness. You can potentially get it up to 50 HRC or even higher, making it much more wear-resistant. However, you also make it more brittle. It's a tradeoff. This is why some parts are heat treated while others are not depending on the applications. Think of a knife. The blade needs to be hardened but the handle might not.

The Takeaway

The Rockwell C hardness of 1018 steel is a key indicator of its properties. It's not super hard, which makes it easy to machine and weld, making it a versatile choice for a wide range of applications. But remember, it’s the balance of hardness, strength, and other properties that makes 1018 steel such a workhorse material in the world around us. Next time you see a sturdy bolt or a precisely cut gear, you might just be looking at the result of understanding the humble, but reliable, properties of 1018 steel.