Alright, buckle up buttercups, because we're diving into the wonderfully weird world of welding! Specifically, we're talking about TIG welding aluminum, and a little something called polarity. Think of it like choosing the right shoes for a dance-off.

You wouldn't wear flip-flops to a tango, would you? Same goes for polarity! It’s all about how the electricity flows, like a tiny river of zaps trying to join two pieces of metal in holy matrimony.

The Great Aluminum Welding Puzzle

Aluminum, bless its shiny little heart, is a bit of a drama queen when it comes to welding. It’s got this incredibly stubborn oxide layer – think of it as a bodyguard made of pure, unyielding stubbornness – that refuses to let the weld join the party.

That's where polarity comes to the rescue! It's the secret handshake, the password to bypass that grumpy oxide layer.

Alternating Current (AC): The Two-Faced Friend

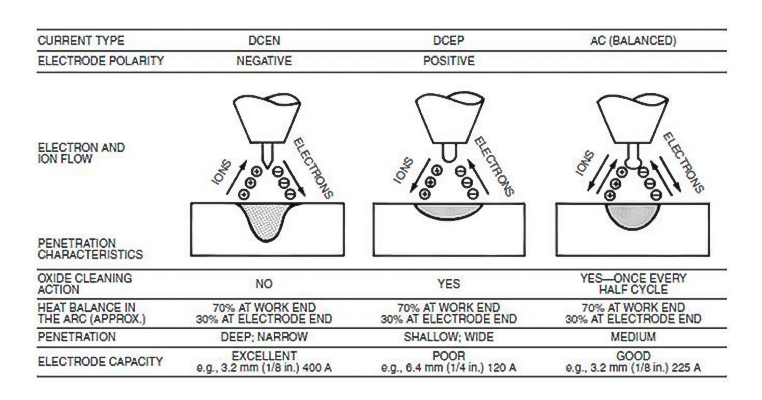

Now, for aluminum, the go-to hero is usually AC, or Alternating Current. Imagine AC as a very indecisive friend. It switches directions constantly, going one way, then the other, like a pendulum swinging back and forth.

This switching is the key! One direction of the current cleans that pesky oxide layer, blasting it away with tiny electrical explosions.

The other direction of the current focuses on actually melting the aluminum and joining it together. It's a delicate dance of cleaning and joining, all happening faster than you can say "arc welding!"

Direct Current Electrode Negative (DCEN): The One-Way Street

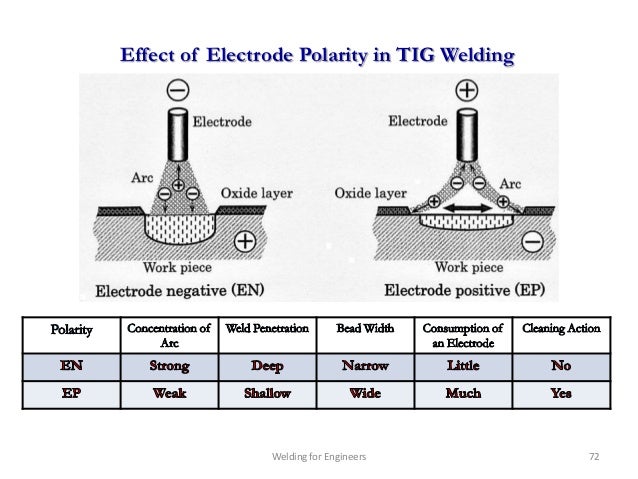

Now, let's talk about DCEN, or Direct Current Electrode Negative. This is like a one-way street for electricity, flowing consistently in one direction.

With DCEN, most of the heat is concentrated at the workpiece. This makes it great for thicker materials and deeper penetration, but it doesn't do much for that oxide layer.

Think of it as trying to build a sandcastle on a beach already covered in seaweed - you'll just end up with a seaweed-infused sandcastle.

Direct Current Electrode Positive (DCEP): The Unexpected Twist

Then there’s DCEP, Direct Current Electrode Positive. This is where things get interesting, and sometimes a little… well, explosive.

With DCEP, the heat is concentrated at the electrode – the tungsten that’s delivering the electricity. This means you're basically trying to weld with a hot, melting ice cube.

It's not ideal for aluminum! You’ll end up melting your tungsten electrode faster than you can say "welding mishap."

The Polarity Party Trick: Balancing the Act

The real magic happens when you understand that welding is all about balance. It's like being a tightrope walker, constantly adjusting to stay upright.

With AC, you’re constantly balancing the cleaning action with the welding action. You can even adjust the balance of the AC waveform to spend more time cleaning or more time welding!

Some fancy welding machines let you tweak this balance like a DJ mixing music. It's all about finding that sweet spot where you get a clean, strong weld without melting everything in sight.

Tales from the Workshop: Polarity Gone Wild

I once saw a guy trying to weld aluminum with straight DCEP. It wasn't pretty. Sparks flew, the tungsten electrode turned into a molten ball, and the aluminum remained stubbornly unwelded.

It was like watching a culinary student try to bake a cake with a blowtorch. Impressive in a chaotic, ultimately unsuccessful way.

Another time, I saw someone perfectly balancing their AC settings. The weld was beautiful, a shimmering silver line holding two pieces of metal together like they were always meant to be.

Embrace the Zap: Finding Your Polarity Groove

So, what's the takeaway from all this polarity talk? Don't be afraid to experiment! Welding, especially TIG welding aluminum, is a journey of discovery.

It’s about learning to listen to the arc, to feel the heat, and to understand how the electricity is flowing. Every weld is a tiny experiment, a chance to learn something new.

And remember, even the most experienced welders have their "oops" moments. The important thing is to learn from those mistakes, adjust your settings, and keep on zapping!

Beyond the Basics: A Glimpse into the Future

The world of welding is constantly evolving. New technologies and techniques are emerging all the time. Pulse welding, for example, is a technique that involves pulsing the welding current to control heat input and improve weld quality.

Think of it as giving the weld a little "rest" between pulses, allowing it to cool down and prevent distortion. It's like interval training for metal!

And who knows what the future holds? Maybe one day we'll have welding robots that can perfectly adjust polarity on the fly, creating flawless welds every time. Until then, it's up to us to master the art of the zap.

A Final Spark of Wisdom

Welding aluminum with TIG isn't just about melting metal; it's about understanding the science, embracing the art, and finding your own unique style.

It's about turning raw materials into something beautiful and functional. So, grab your torch, dial in your polarity, and let the sparks fly!

Just remember to wear your safety glasses. And maybe a fireproof apron. You know, just in case.