Alright folks, let's talk aluminum MIG welding. Specifically, the whole "polarity" thing. Now, polarity might sound like some advanced physics term that makes your head spin, like trying to understand quantum entanglement while simultaneously balancing a stack of pancakes. But trust me, it's not nearly as scary. It's more like deciding which way to hang your toilet paper – there's a "right" way, and a "wrong" way that'll just lead to frustration.

Think of it this way: electricity needs a path, right? It's like a tiny, energized hamster running on a wheel. It needs to get from point A to point B. Polarity, in welding terms, just dictates which direction that hamster runs. And in aluminum MIG welding, that hamster really wants to run a certain way.

The Magic Words: DCEP (or Reverse Polarity)

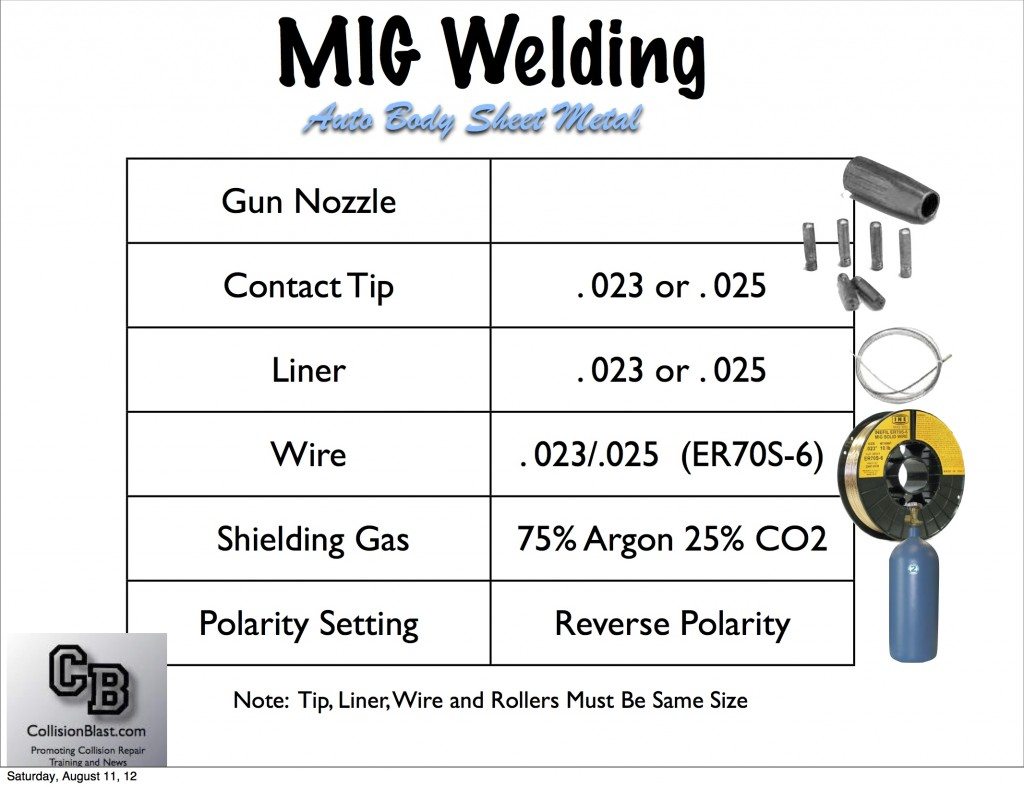

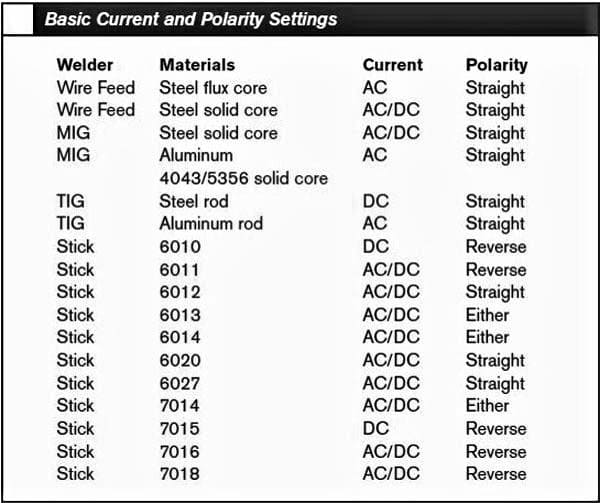

The secret phrase you need to remember is DCEP, which stands for Direct Current Electrode Positive. (Some folks call it reverse polarity, which is just another way of saying the same thing). Okay, breathe. We're not going to dive into the nitty-gritty of electron flow. All you need to know is that with aluminum MIG, you absolutely, positively, without a doubt want your electrode (the welding wire) to be connected to the positive side of your welding machine.

Why? Well, here's where it gets a little "science-y," but I promise to keep it light. Aluminum naturally forms a layer of oxide on its surface. This oxide is tough stuff, a real party pooper when you're trying to melt the aluminum underneath. DCEP (reverse polarity) helps to blast away that oxide layer before the welding arc really gets going. It's like having a tiny, electrified sandblaster built into your welding gun.

Imagine trying to cook an egg in its shell without cracking it first. You'd just end up with a lukewarm, hard-boiled egg in a ridiculously strong shell. That oxide layer is the shell. DCEP is the crack that lets the heat get to the good stuff.

What Happens if You Get it Wrong? (DCEP vs. DCEN)

So, what happens if you accidentally hook your welding machine up for DCEN (Direct Current Electrode Negative), also known as straight polarity? Oh boy. Buckle up for a sputtering, popping, and generally unpleasant experience. You'll likely end up with a weld that looks like a confused bird built a nest out of molten metal. Think of it like trying to build a sandcastle during high tide – it's just not going to work.

DCEN polarity will give you a weld bead that sits *on top* of the aluminum, without properly fusing to it. It will often be black and sooty. It is essentially a cold lap, creating zero structural support. Welding aluminum with DCEN polarity is one of the surest ways to guarantee your weld will fail.

Here's a little anecdote: I once saw a guy trying to weld aluminum with DCEN. He was getting nowhere, the aluminum was just bubbling and spitting, and he was getting increasingly frustrated. He kept muttering to himself, "I just don't get it! I'm using the right wire, the right gas…". After about an hour of this, I politely asked him, "Hey, are you sure your polarity is set correctly?". The look on his face was priceless. He'd completely overlooked the most fundamental setting! A quick switch to DCEP, and he was laying down beautiful beads in no time. We all make mistakes, that's what makes us human.

The Easy Way to Remember

So, how do you remember which polarity to use? Just picture this: Positive aluminum! Aluminum needs a positive attitude (or, in this case, a positive electrode) to really shine. And remember, a good aluminum weld should be smooth, shiny, and strong – a testament to the power of properly applied DCEP.

So next time you're tackling an aluminum MIG welding project, double-check your polarity. It's the simplest thing to get wrong, but it makes all the difference in the world. Think of it as the secret sauce that turns your aluminum welding from a frustrating mess into a satisfying masterpiece. Now go out there and weld like a pro! Good luck and happy welding!