Alright folks, let's talk about aluminum TIG welding polarity. I know, I know, it sounds like something out of a Star Trek episode. But trust me, it’s way less complicated than warp drive. Think of it like choosing the right socks for your shoes. You wouldn't wear wool socks with sandals (unless you're trying to make a statement…a questionable one). Just like there's a sock-shoe etiquette, there's a polarity etiquette for TIG welding aluminum.

AC: The Dynamic Duo

For aluminum, we almost exclusively use AC (Alternating Current). Why AC? Well, imagine your aluminum piece is a messy teenager's bedroom. It's got a layer of grime and oxidation – the aluminum oxide layer, which has a melting point way higher than the aluminum itself. AC is like having a cleaning crew that comes in, tidies up, and then lets the teenager do their thing.

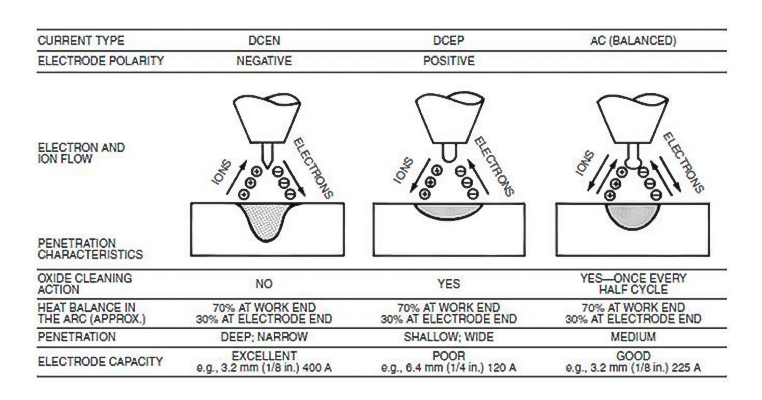

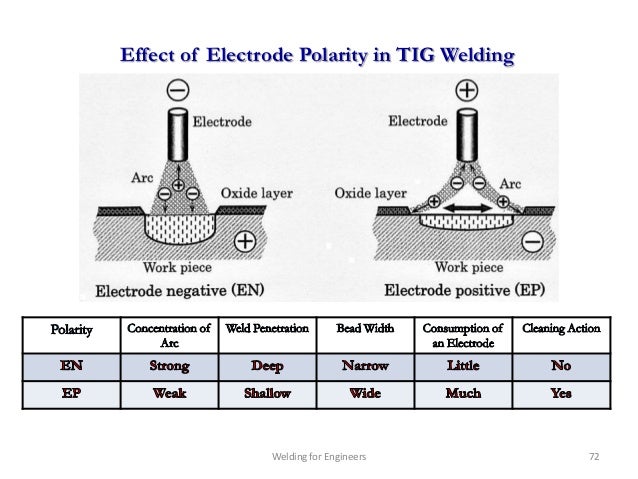

One half of the AC cycle (the positive side) acts like our cleaning crew. It blasts away that oxide layer, a process often referred to as "cathodic cleaning". Think of it like power washing all the gunk off before you start welding. The other half of the AC cycle (the negative side) is where the heat really gets put into the metal, allowing you to actually fuse the aluminum together. So, it's a back-and-forth dance: clean, heat, clean, heat. A beautiful, molten ballet!

Why Not DC? (Usually)

Now, you might be thinking, "Hey, I've heard of DC welding. Can't I just use that?" Well, in most cases, for aluminum, DC welding isn’t the best choice. It's like trying to cut steak with a butter knife. You *might* be able to do it, but it’ll be a messy, frustrating experience.

DCEN (Direct Current Electrode Negative), which is where the electrode is negative, puts a lot of heat into the workpiece, but doesn't do much for cleaning. You end up with a weld that's contaminated with that pesky oxide layer. Think of it as trying to paint a wall without sanding it first. The paint just won't stick properly!

DCEP (Direct Current Electrode Positive), where the electrode is positive, does the cleaning action, but it also puts a *ton* of heat into your tungsten electrode. This often leads to the electrode melting or spitting, which isn't ideal. Imagine trying to cook a steak by setting the pan on fire – that's DCEP in a nutshell.

There *are* some specialized DC welding processes for aluminum, but they're pretty niche and usually require specialized equipment. We're sticking to the basics here, folks.

The Balancing Act: AC Balance

Now, things get a little more interesting. Most AC TIG welders allow you to adjust the AC Balance. This essentially lets you tweak how much time the cycle spends cleaning versus heating. Think of it as telling the cleaning crew to spend more time on the really dirty spots or letting the teenager have more time to actually build their Lego masterpiece.

Higher AC Balance (more cleaning) is great for really dirty aluminum or if you're having trouble getting a clean weld. But be careful, too much cleaning can erode your tungsten electrode faster. Lower AC Balance (more heat) is good for thicker aluminum or when you need to penetrate deeper into the material. But you need to make sure your material is clean otherwise you'll just weld the contamination into the piece.

Frequency: The Rhythm of the Weld

Another fun setting is AC Frequency. This adjusts how fast the current alternates between positive and negative. A higher frequency creates a narrower arc, good for detail work. A lower frequency creates a wider arc, good for filling gaps. Think of it like adjusting the speed of a painter's brush. A faster brush is good for fine lines, while a slower brush is better for broad strokes.

The Bottom Line

So, there you have it: a crash course in aluminum TIG welding polarity. Remember, AC is your go-to choice for most aluminum welding. Experiment with your AC Balance and Frequency settings to find what works best for your specific project. And most importantly, have fun! Welding should be enjoyable, not a source of frustration. Just like picking the right socks for your shoes, once you find the right setting, everything just clicks. And if it doesn’t? Well, that’s what grinding wheels are for!