Alright, let's talk aluminum MIG welding and the bizarre world of polarity. Trust me, it's way more interesting than it sounds!

Think of polarity as the electrical "on" switch. It dictates the direction electricity flows. Sounds simple, right? Wrong! When you're wrestling with aluminum, it's a whole different ballgame.

Why Polarity Matters (Especially for Aluminum)

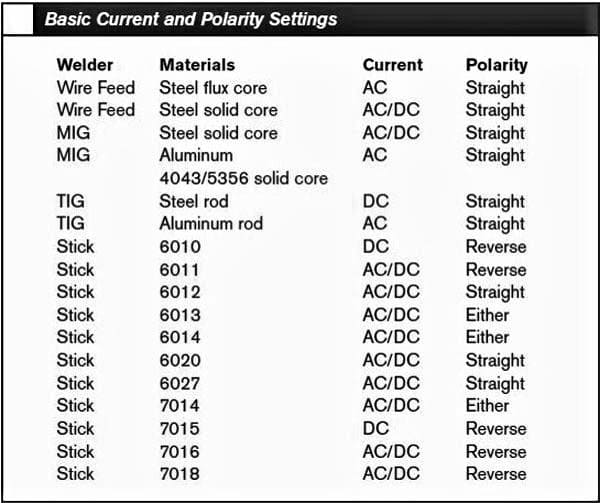

Steel? Usually, you're rocking DCEP (Direct Current Electrode Positive). It's like a warm hug for your steel. Aluminum? Nope. That's where we embrace the weird: AC or DCEN (Direct Current Electrode Negative). And often, specifically, AC.

Wait, why? Here's the quirky part. Aluminum forms a stubborn oxide layer. It's like a bodyguard that prevents proper welding. DCEN, or even better, AC, helps blast through that oxide.

Imagine trying to paint over a dusty surface. You gotta clean it first, right? AC welding does just that – cleans the aluminum as it welds!

Think of AC as alternating between cleaning and welding. It's like a two-step dance for electricity.

DCEN: The Cold Shoulder (Sometimes)

DCEN (Direct Current Electrode Negative) puts the heat at the workpiece (your aluminum). This can be useful for thicker aluminum. Less heat on the electrode means it won't melt back as easily, allowing for a more stable arc. Sometimes.

But... there's always a but, isn't there? DCEN *alone* doesn't do a fantastic job of blasting away that oxide layer. That's why it's less common than AC for most aluminum MIG welding.

AC: The Party Animal

Now, AC (Alternating Current) is the real star of the show! It's constantly switching between positive and negative. This flipping action does two key things:

1. Oxide Removal: When the electrode is positive, it cleans the aluminum surface like a tiny sandblaster.

2. Deep Penetration: When the electrode is negative, it melts the aluminum and creates a strong weld.

It’s like having a tiny, electric superhero that cleans and welds simultaneously. Who needs a cape when you have alternating current?

This constant flipping creates a self-cleaning action, which is vital for aluminum. Without it, you'll end up with a weld full of inclusions and porosity. That’s welder-speak for "a really bad weld."

The Funky Frequency Factor

Even with AC, there's more fun to be had! You can often adjust the frequency. Think of frequency like the tempo of a song. Higher frequency = faster cleaning and a narrower weld bead.

Lower frequency? A wider, more penetrating weld. It’s all about finding the right rhythm for your aluminum project.

Balance is Key (Literally!)

Some fancy welding machines let you adjust the AC balance. This controls the amount of time spent in the positive (cleaning) and negative (penetration) phases. More cleaning? Less penetration. More penetration? Less cleaning. It's a balancing act.

Why This is Just Plain Fun

Okay, so maybe "fun" is a stretch for everyone, but think about it. You're controlling electricity! You're manipulating the very flow of electrons to join two pieces of metal together. And you're doing it with a metal that's famous for being a pain to weld. How cool is that?

Understanding polarity for aluminum MIG welding is like unlocking a secret code. It lets you create strong, beautiful welds that would otherwise be impossible.

Plus, you can impress your friends with your newfound welding knowledge. "Oh, you're welding aluminum? Are you using AC? What's your frequency? What's your balance?" They'll be so impressed (or annoyed)!

Don’t Be Scared to Experiment!

Ultimately, the best way to learn about polarity is to experiment! Grab some scrap aluminum, fire up your MIG welder, and play around with the settings. See what happens when you change the polarity, frequency, and balance.

Don't be afraid to make mistakes. That's how you learn. And hey, even if you mess up, you'll still have a cool story to tell.

So go forth, conquer your fear of aluminum, and embrace the weird and wonderful world of polarity! You might just surprise yourself.

Happy welding!