Stainless steel: the unsung hero of modern life. From gleaming kitchen appliances to the structural bones of skyscrapers, this versatile alloy is everywhere. But working with it? That's traditionally been a challenge. Enter the plasma cutter, a tool that's making stainless steel projects accessible to a whole new wave of DIY enthusiasts and professionals alike.

The Plasma Cutter: Not Your Grandfather's Blowtorch

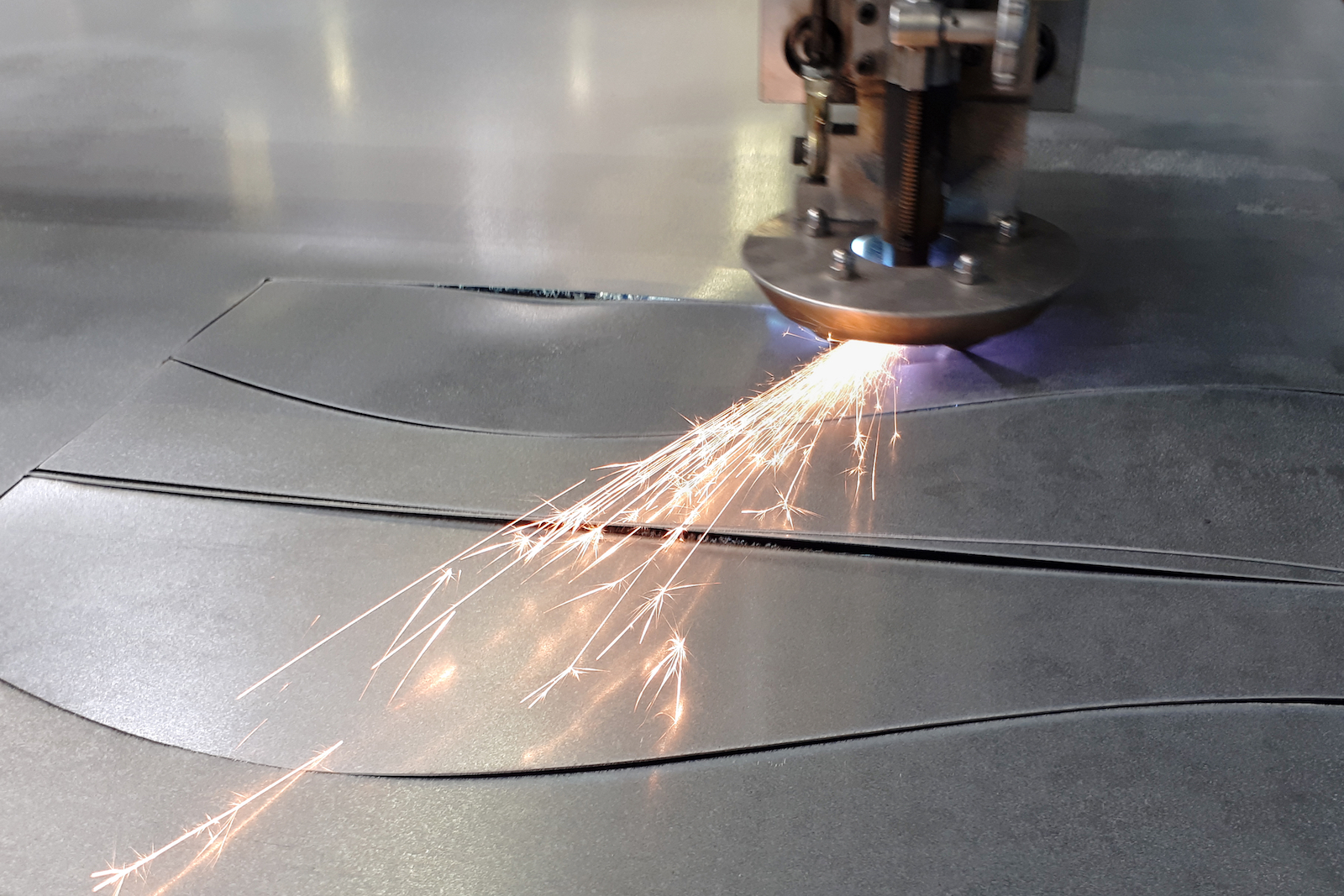

Forget the image of a grizzled welder hunched over a hissing oxy-acetylene torch. A plasma cutter is a far more streamlined, dare we say elegant, solution. Think of it as a high-tech lightsaber for metal. Okay, maybe not quite, but the principle is similar: ionized gas, heated to extreme temperatures, creates a plasma arc that melts through the steel with impressive speed and precision.

Why plasma? Because it offers several advantages over traditional methods:

- Cleaner cuts: Less slag, less cleanup.

- Faster speeds: Time is money, right?

- Greater versatility: Cuts through various thicknesses of stainless steel.

- Easier to use: Modern plasma cutters are user-friendly, even for beginners.

Stainless Steel: A Material Worth Knowing

Before we dive deeper, let's appreciate stainless steel for a moment. It's not just about good looks. The "stainless" part comes from the chromium content, which forms a passive layer of chromium oxide, preventing rust and corrosion. It’s this self-healing ability that makes it perfect for everything from surgical instruments to outdoor sculptures.

Fun fact: The Statue of Liberty contains about 80 tons of stainless steel, ensuring her majestic presence for generations to come. Now that's some serious staying power.

Plasma Cutting Stainless Steel: The Art and the Science

So, you're ready to unleash your inner metal artist? Here are some practical tips for plasma cutting stainless steel:

- Safety First: This isn't a game. Wear appropriate PPE: welding helmet (with the correct shade lens), gloves, and a flame-resistant jacket. UV radiation is no joke.

- Choose the Right Cutter: Match the cutter's amperage to the thickness of the steel. A low amperage will struggle, a high amperage could cause excessive melting.

- Cleanliness is Key: Remove any rust, paint, or grease from the cutting area. This ensures a clean, consistent cut.

- Set the Amperage Correctly: Refer to your plasma cutter's manual for recommended settings based on the steel thickness.

- Maintain a Steady Hand: Smooth, consistent movement is essential for a clean cut. Practice on scrap metal first. Think of it like practicing your brushstrokes before painting a masterpiece.

- Use a Guide: For straight cuts, clamp down a metal straight edge. For curved cuts, use a template. Precision is your friend.

- Air Quality Matters: Use a clean, dry air supply. Moisture in the air can damage the cutter and affect the cut quality.

Pro Tip: For thicker stainless steel, consider using a water table. This helps to cool the metal and reduce warping.

Beyond the Workshop: Stainless Steel in Our Lives

Stainless steel and plasma cutting aren't just confined to industrial settings. Imagine crafting custom stainless steel house numbers for your home, building a sleek stainless steel countertop for your outdoor kitchen, or creating unique metal art for your garden. The possibilities are endless!

Think of the iconic architect Frank Gehry, whose buildings often feature flowing, sculptural forms of stainless steel. His work demonstrates the incredible potential of this material when combined with creative vision and the right tools. While we may not all be Gehry, a plasma cutter empowers us to bring our own visions to life.

The Ripple Effect

In a world that often feels mass-produced and disposable, learning a skill like plasma cutting offers a powerful sense of agency. It's about more than just cutting metal; it's about taking control, creating something unique, and connecting with the tangible world around us. It's a reminder that even in our increasingly digital lives, the ability to work with our hands and shape our environment remains deeply satisfying and profoundly human. Perhaps, just perhaps, it's a way to rediscover a little bit of that "maker" spirit that resides within us all.