Hey, pull up a chair! Let's talk injection molds. Sounds super exciting, right? Okay, maybe not to everyone, but trust me, once you peek inside these metal behemoths, you’ll appreciate the magic behind that plastic thingamajig you’re holding. So, what’s inside?

The Big Players: Clamping Unit and Injection Unit

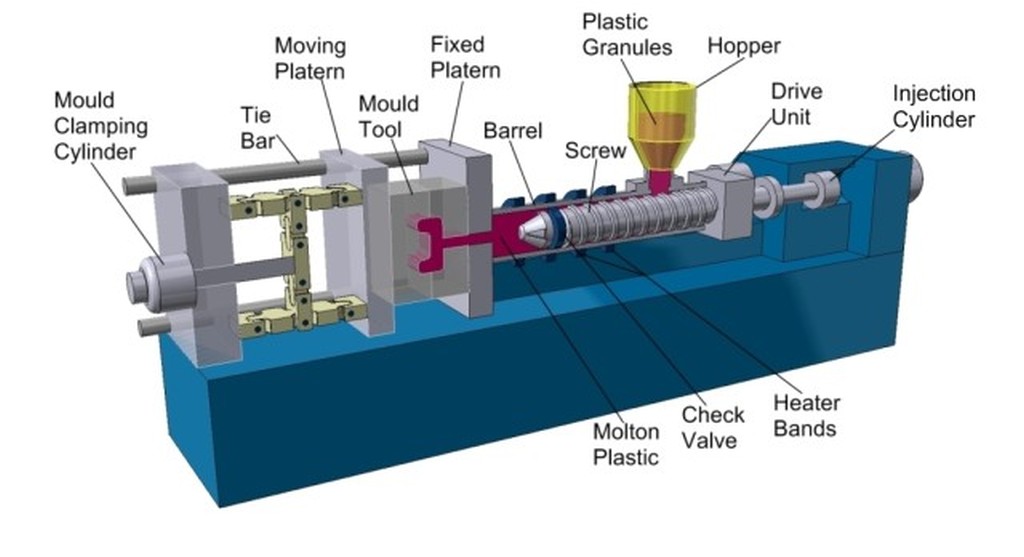

First, imagine a giant sandwich press. Kinda. That's essentially what the clamping unit does. It's the muscle that holds the two halves of the mold together during the injection process. Think of it as the bouncer at the plastic party, making sure nobody sneaks out early. Important job!

Then you've got the injection unit. This is where the molten plastic (we're talking seriously hot stuff) gets squirted into the mold cavity. It’s like the chef carefully squeezing frosting onto a cupcake...but instead of frosting, it's molten plastic. And instead of a cupcake...well, you get the idea.

Diving into the Mold Itself

Okay, now for the juicy bits. Let’s crack open that mold! (Metaphorically, of course. Please don't actually crack open a mold.) Inside, you'll find a whole cast of characters.

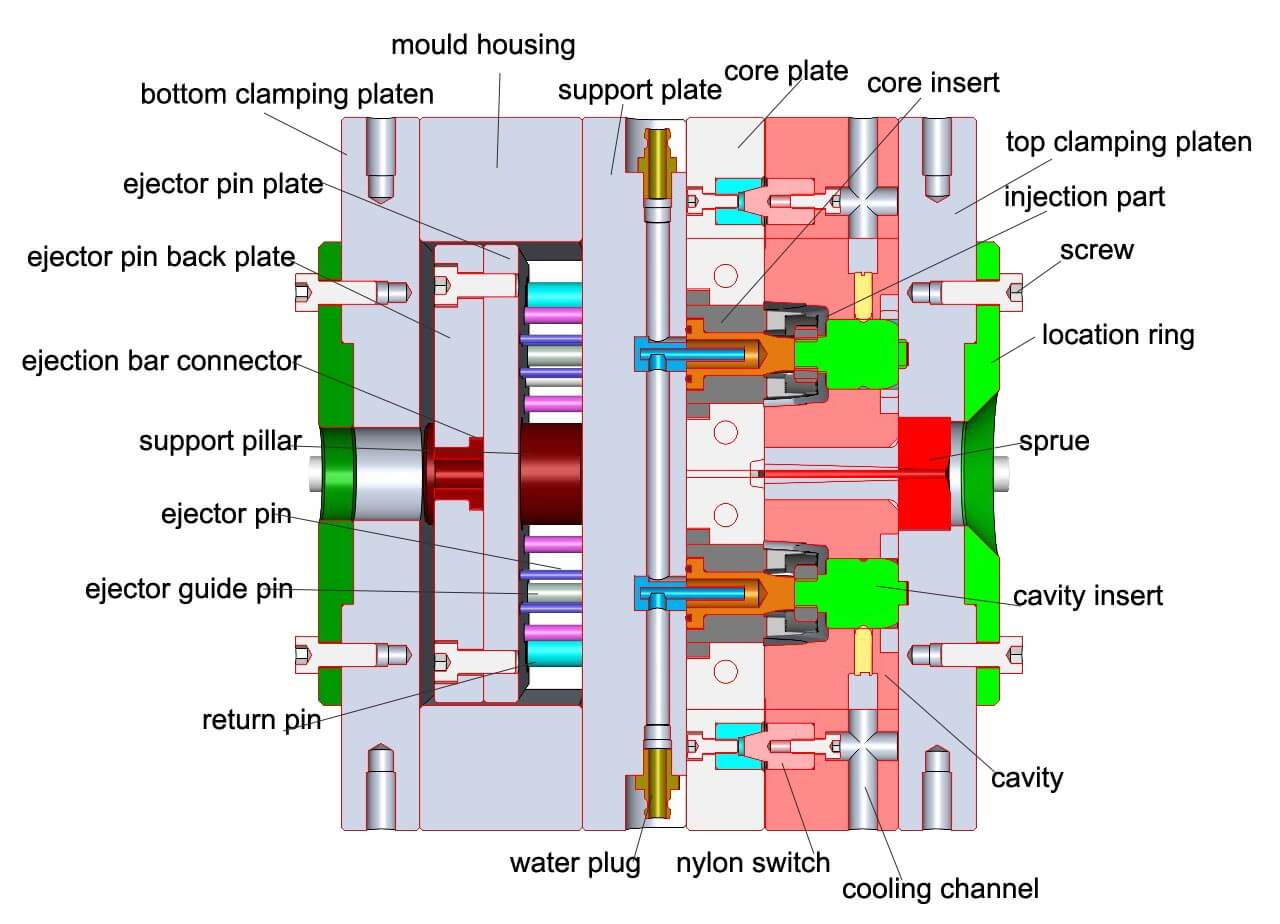

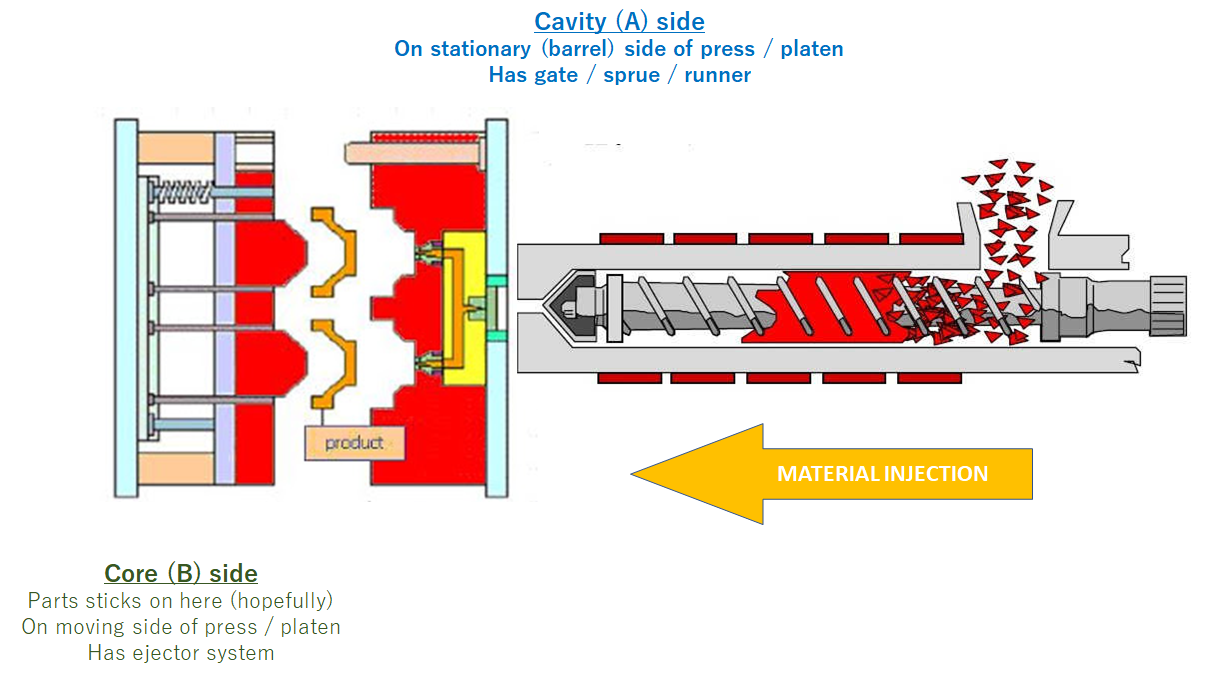

First, there are the mold halves (or mold plates). We usually call them the A-side and B-side. They come together to form the cavity – the actual shape of your final plastic part. Think of it as the cookie cutter that defines your cookie. No cookie cutter, no cookie, right?

The cavity itself is probably the most important part. This is where all the magic happens! This is the negative space that defines the dimensions of the plastic part that you're looking to create.

The Supporting Cast: Making it all Flow

But wait, there's more! Getting that molten plastic into the cavity isn't as simple as just squirting it in. That's where the sprue comes in. It’s the main channel where the plastic first enters the mold. Think of it as the main highway leading to your destination. No sprue, no plastic traffic!

The sprue then branches out into runners. These are smaller channels that distribute the plastic to multiple cavities (if you're making more than one part at a time). Basically, runners are like the city streets that deliver the plastic goods to each individual house (cavity).

And finally, we reach the gates. These are the little doorways that connect the runners to the actual cavity. They control the flow of plastic into the cavity and are designed to be easily removed after the part is molded. A tiny little bouncer at the door!

Keeping Things Cool (Literally)

Alright, now that we've filled the mold with molten plastic, we need to cool it down. Enter the cooling channels! These are passages drilled through the mold where coolant (usually water) circulates to solidify the plastic. Imagine tiny little rivers flowing through the mold, keeping things chill. Without these, you'd have a melty, warped mess. No one wants that, right?

Ejecting the Masterpiece

Once the plastic is cool and solid, it's time to pop it out! This is where the ejection system comes in. Typically, this involves ejector pins that push the part out of the mold. They are like little fingers poking the finished part out of its cozy metal home.

The Extras

Oh, and let's not forget about things like venting. You need a way for the air in the cavity to escape as the plastic rushes in, otherwise you'll get air pockets and incomplete parts. Think of it as letting out a little burp of air so everything flows smoothly. Rude in real life, essential in injection molding.

And then there are guide pins which ensure the two halves of the mold align perfectly every time. Precision is key in this game!

So, there you have it – a whirlwind tour of the parts of a plastic injection mold! It's a complex process, but hopefully, now you have a better understanding of what's going on inside. Who knew so much went into that humble plastic widget? Now, who wants another cup of coffee?