Ever stared at a welding rod and wondered, "What's with all the numbers and letters?" You're not alone! It might seem like a secret code, but it's actually a super helpful system for knowing exactly what kind of weld you're going to create. Think of it like the ingredient list on your favorite snack – it tells you everything you need to know (without the weird chemicals, hopefully!). So, let's decode this welding rod language together, shall we?

Decoding the E: Your Electrode's Passport

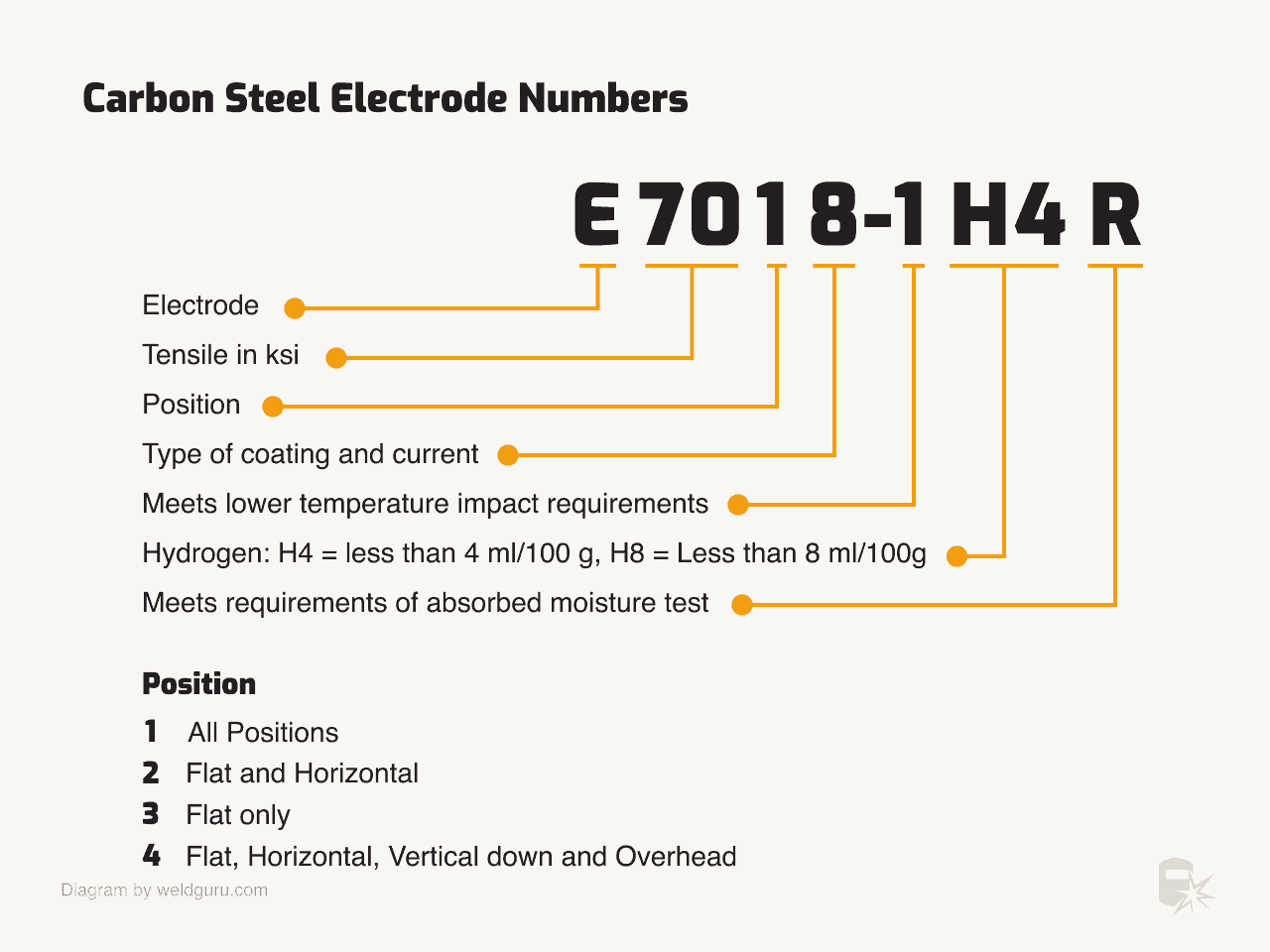

The first thing you'll usually see is an "E." This is like saying "Hello, I'm an electrode!" It’s the universal sign that you're dealing with a welding rod designed to carry an electrical current and deposit filler metal. Simple enough, right?

The First Two (or Three) Numbers: Tensile Strength - How Strong is Your Weld?

Next up are the first two or three numbers. These guys are all about tensile strength. Tensile strength is basically how much pulling force the weld can withstand before it breaks. Think of it like this: if you have two cars chained together by a weld, this number tells you how hard you can yank on those cars before the weld snaps. Cool, huh?

So, let's say you see "E7018." The "70" (or "70,000" in this case) tells us that the weld can handle 70,000 pounds per square inch (psi) of pulling force. Higher number, stronger weld. Makes sense, right? It's like choosing between a tiny paperclip and a thick steel cable to hold something heavy – you want the one that can handle the job!

Note: For some rods, there will be three numbers instead of two to indicate the tensile strength. Just remember to add those three zeros!

The Third Number: Welding Positions - Where Can You Weld?

This number is all about welding positions. Can you weld flat, horizontal, vertical, or overhead? This number tells you! It's like the agility score for your welding rod.

- "1" means you can weld in all positions: flat, horizontal, vertical, and overhead. Pretty versatile, right?

- "2" typically means you can only weld in flat and horizontal positions.

- There are other numbers too, each with its own set of position limitations, so always check the specifics!

Think of it like this: a "1" is like a gymnast who can do flips on any surface, while a "2" might be more comfortable on the floor. Knowing this number helps you choose the right rod for the specific welding job you're tackling.

The Last Number: The Magic Number - What Kind of Current & Coating?

This is where things get a little more nuanced. The last number is a bit of a catch-all, indicating things like the type of coating on the rod (flux) and the type of current (AC or DC) you need to use. Think of it as the secret ingredient in your welding recipe!

Different last digits denote different flux types. For example, an "8" in the E7018 example indicates a low-hydrogen coating that is excellent for high-strength welds and works well with DC current. Flux coatings help to shield the weld pool from atmospheric contaminants, creating a cleaner and stronger weld.

There are a bunch of different flux types, each with its own pros and cons. Some are great for specific materials, others for specific welding techniques. That's why it's crucial to check the manufacturer's recommendations for your specific rod!

Why does the last number matter? Because using the wrong current or coating can lead to weak welds, spatter, and other headaches. It’s like using the wrong type of oil in your car – it might run for a while, but eventually, something's gonna break!

Beyond the Basics: Letters and Other Markings

Sometimes you'll see extra letters after the numbers, like "H4" or "M." These usually refer to specific properties or composition details. "H4," for example, indicates a low-hydrogen rod with a specified hydrogen content. The “M” indicates that the rod meets certain military specifications.

Why is all this so cool?

Because understanding these markings empowers you! You're not just blindly welding; you're making informed decisions about the materials you're using and the welds you're creating. It’s like leveling up your welding skills from "beginner" to "knowledgeable professional." It allows you to tailor your welds to meet the specific demands of the project, ensuring safety and durability. Plus, knowing this stuff impresses people – trust me!

So next time you pick up a welding rod, remember this little guide. Decode those numbers, understand their meaning, and weld with confidence! Happy welding!