Ever wonder how they make sure amusement park rides are safe, or that the airplane you're flying on isn't about to have a catastrophic structural failure? Well, one important tool in the toolbox is something called Magnetic Particle Inspection (MPI). It sounds super technical, and in some ways it is, but the basic principle is actually pretty cool, and understanding it can give you a whole new appreciation for the things around you.

So, what's MPI used for? Primarily, it's used to detect surface and near-surface cracks and flaws in ferromagnetic materials. That means metals like iron, steel, and nickel – materials that are easily magnetized. Think of it as a way to see the invisible imperfections that could weaken a part. For beginners, imagine trying to find a tiny scratch on a black car in the dark. MPI is like using a special flashlight that makes that scratch glow! It helps find problems before they become bigger, more dangerous, and much more expensive.

Why is this important for different people? Well, for engineers and manufacturers, MPI is crucial for quality control. They use it to ensure their products meet safety standards and to prevent failures in the field. For hobbyists, like those who restore old cars or motorcycles, MPI can be invaluable for identifying hidden cracks in critical components like engine parts or suspension systems, ensuring a safe and reliable restoration. Families benefit indirectly through the increased safety of the products and infrastructure they use every day, from the cars they drive to the bridges they cross.

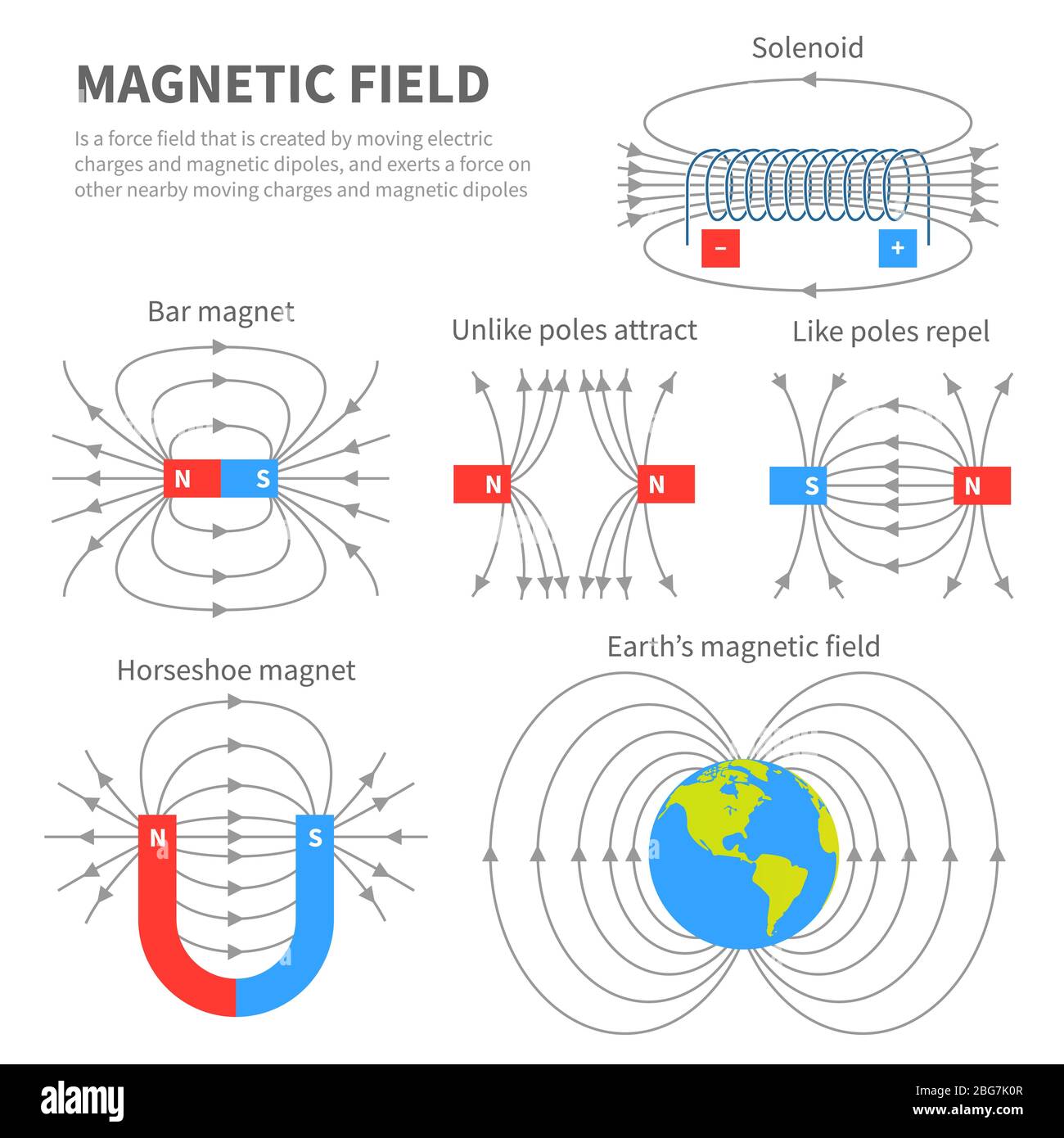

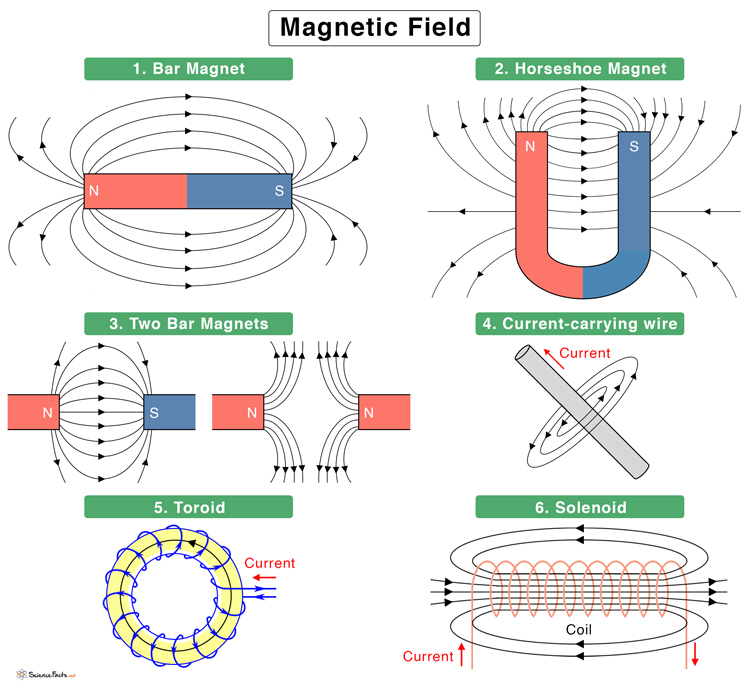

Here's how it works in a nutshell: The part being inspected is magnetized. Then, tiny magnetic particles (usually iron oxide) are applied to the surface. If there's a crack or flaw, it disrupts the magnetic field, causing the magnetic particles to gather around the flaw, making it visible. Think of it like iron filings lining up along a magnet's force field, except in this case, the “force field” is disturbed by a tiny crack.

There are a couple of variations. You can use dry particles or wet particles suspended in a liquid carrier. You can also apply the magnetic field using different methods, like passing an electric current through the part or using a magnetic yoke. The best method depends on the size and shape of the part, and the type of flaws you're looking for.

Want to learn more? A great place to start is by watching some videos online. Search for "Magnetic Particle Inspection demonstration" on YouTube. You'll see real-world examples of how the process is used. Also, many community colleges offer courses in non-destructive testing, which includes MPI. Even a basic understanding of the principles can be fascinating.

While you might not be performing MPI inspections yourself anytime soon, understanding its purpose – to find those hidden flaws and ensure safety – can give you a newfound appreciation for the engineering and quality control that goes into the things we rely on every day. It’s a reminder that even though we can’t always see it, there are people and processes working behind the scenes to keep us safe and sound. So next time you see a piece of heavy machinery or a perfectly smooth weld, remember that MPI, and techniques like it, might have played a role in ensuring its integrity!