Okay, let's talk rust. Not the romantic, antique-store-find kind of rust, but the kind that's eating away at your gutters or that old metal bucket you're trying to upcycle. Specifically, we're diving into how to make galvanized metal rust. Seems counterintuitive, right? Galvanization is supposed to *prevent* rust! But stick with me, it's more fascinating than it sounds, and sometimes, you *want* that rusty patina.

Think of galvanized metal like a knight in shining armor. That armor is a coating of zinc, protecting the steel underneath from the nasty elements that cause rust – namely, oxygen and water. The zinc acts as a sacrificial lamb, corroding *before* the steel does. That's why galvanized steel lasts so long.

Why Would You *Want* Rust, Though?

Good question! It's not about destruction, necessarily. Sometimes, you want a specific aesthetic. That aged, weathered look can be gorgeous. Imagine using corrugated galvanized metal as a backdrop for a garden, but you want it to look like it's been there for ages. Or perhaps you're building a rustic-chic side table and want the metal legs to have that perfectly imperfect, vintage vibe.

Plus, sometimes the existing galvanization is already damaged, and you're dealing with peeling, uneven surfaces. Encouraging controlled rust can help you achieve a more uniform, consistent look before you paint or seal the metal for long-term protection. It's like giving the project a head start in aging gracefully!

The "Accelerated Aging" Process

So, how do we speed up the rusting process? It's all about breaking down that protective zinc coating and exposing the steel to the elements. Here are a few tried-and-true methods:

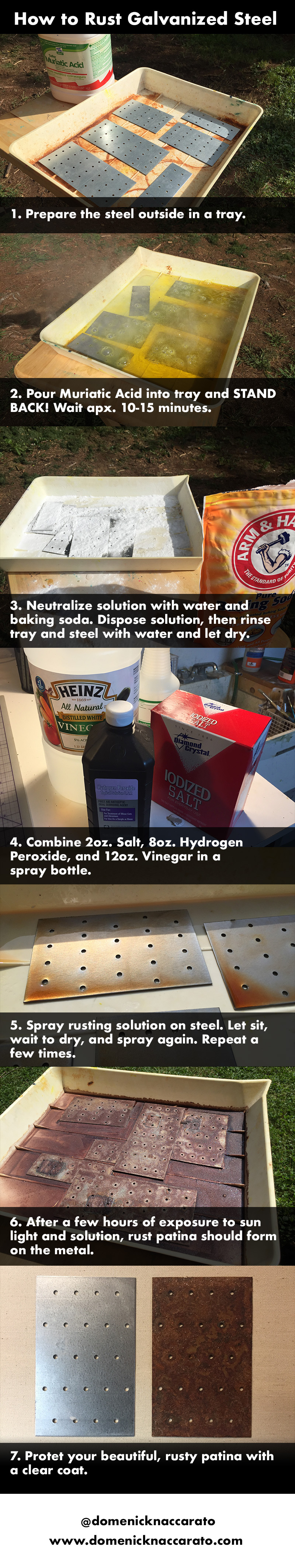

1. The Acid Wash (But Be Careful!)

This is the most aggressive method, and it requires extreme caution. We're talking about using acids like vinegar (the mildest option), muriatic acid (much stronger and potentially dangerous), or even specific rust-inducing chemicals.

Think of it like this: you're giving that zinc coating a really, *really* bad day. The acid eats away at the zinc, opening up the steel to the oxygen and moisture it craves (in a corrosive way, of course).

Important: Always wear appropriate safety gear – gloves, eye protection, and a respirator (especially with stronger acids). Work in a well-ventilated area. Follow the product instructions carefully. And *always* test a small, inconspicuous area first! This isn't like baking cookies; mistakes can be harmful.

To use vinegar, simply soak the galvanized metal in it, or repeatedly wipe it down over several days. For stronger acids, application times will be much shorter – think minutes, not days. Rinse thoroughly with water after treatment to neutralize the acid.

2. Salt and Water: Nature's Rust Accelerator

A much gentler, more forgiving method involves salt and water. Remember those coastal towns where everything seems to rust a little faster? That's the salt air at work.

You can mimic that effect by dissolving salt in water and repeatedly spraying or wiping the galvanized metal. The salt acts as an electrolyte, speeding up the electrochemical process of corrosion. Think of it as adding a catalyst to a chemical reaction – things just happen faster.

This method is great for achieving a more gradual, natural-looking rust. It's also less likely to damage the metal if you're not careful. Just be patient – it takes time.

3. Mechanical Abrasion: Roughing It Up

Sometimes, a little elbow grease is all you need. Use sandpaper, a wire brush, or even steel wool to scratch the surface of the galvanized metal. This breaks down the zinc coating and creates more surface area for rust to take hold.

Think of it like prepping a wall for painting – you're creating a "key" for the rust to adhere to. This method is especially effective when combined with the salt and water treatment.

4. Time: The Ultimate Ingredient

Ultimately, time is the most important ingredient in the rusting process. Even without any special treatments, galvanized metal will eventually rust, especially if it's exposed to harsh weather conditions.

The other methods simply accelerate the inevitable. Think of it like this: you can wait for your hair to turn grey naturally, or you can buy a box of dye. Both will eventually get you to the same place, just at different speeds.

Sealing the Deal (Or the Rust, Rather)

Once you've achieved the desired level of rust, it's important to seal it. Otherwise, the rusting process will continue unchecked, eventually weakening the metal.

You can use a clear coat sealant specifically designed for rusty metal, or even a coat of paint. This will lock in the rust and prevent it from spreading further. Think of it as putting a pause button on the aging process.

So there you have it! Rusting galvanized metal might seem like a strange pursuit, but with a little know-how and the right tools, you can achieve that perfect aged look for your next project. Just remember to be safe, be patient, and have fun experimenting!