Okay, so you wanna know about yield stress? Awesome! It's like, the superhero strength of a material. But how do we, mere mortals, figure it out? Don't worry, it's not as scary as it sounds. Grab your coffee (or tea, I'm not judging!), and let's dive in.

First things first: what exactly *is* yield stress? Imagine you're stretching a rubber band. At first, it stretches back to its original shape, right? But if you pull too hard… snap! (Okay, maybe not *snap* every time, but you get the idea.) That point before it gets permanently deformed? That's basically where we start talking about yield stress!

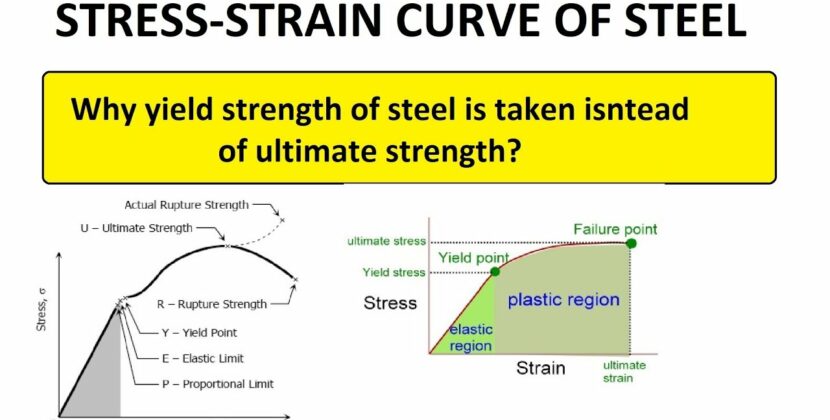

The Stress-Strain Curve: Your New Best Friend

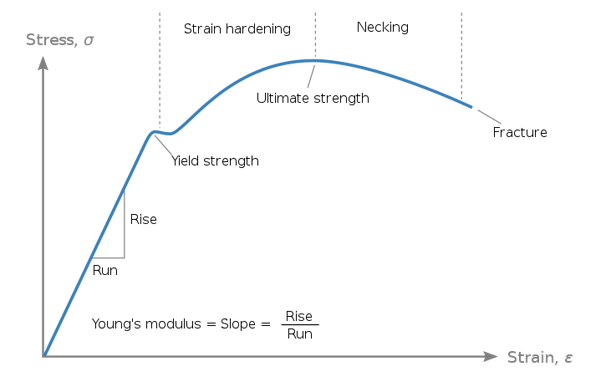

To find the yield stress, we need a stress-strain curve. Sounds intimidating, I know! But trust me, it's just a graph. Stress is how much force you're applying to the material, and strain is how much it's deforming. Think of it like pushing on something and seeing how much it squishes. We all do it!

This curve plots stress on the vertical (y) axis and strain on the horizontal (x) axis. Usually, the curve starts with a straight line. This straight part is the elastic region. The material will return to its original shape if you remove the stress. Ah, good times.

But then the curve starts to bend. Oh oh! This bending indicates we're entering the plastic region. Deformation becomes permanent at this point! That's roughly where we'll find yield stress.

Okay, But *How* Do We Calculate It? (Finally!)

Alright, alright, I hear you. Enough preamble! Here are a couple of common ways to find that elusive yield stress:

The 0.2% Offset Method

This is probably the most popular method, and it's surprisingly straightforward.

1. Draw a line parallel to the initial straight portion of the stress-strain curve.

2. Start this line at a strain of 0.002 (that's 0.2%!).

3. Find where this new line intersects with the stress-strain curve. BOOM! The stress value at that intersection is your 0.2% offset yield stress.

Why 0.2%? Because it's a commonly accepted standard! It's like a handshake agreement among engineers and material scientists. But, you know, with more data points.

The Proportional Limit Method

This one's a little more subjective, but still useful! The proportional limit is the point on the stress-strain curve where it starts to deviate from that initial straight line (elastic region). In other words, where the curve starts to bend.

You basically *eyeball* it. Yup, you read that right. Find the point where the curve just starts to curve. The stress value at that point is your yield stress. It's not super precise, but it can be a quick and dirty estimation.

Important Caveats (Because There Always Are)

Not all materials have a super clear yield point. Some materials have a gradual transition from elastic to plastic behavior. In these cases, the 0.2% offset method becomes even more important!

Also, remember that temperature, strain rate (how fast you're applying the force), and other factors can affect a material's yield stress. So, always consider the specific conditions of your experiment or application. It’s a puzzle you're solving, piece by piece!

So, You're an Expert Now! (Almost)

And there you have it! Calculating yield stress isn't rocket science (though, you know, rocket scientists probably use it too!). With a stress-strain curve and a little know-how, you can determine the strength of a material and predict how it will behave under stress. Pretty cool, right?

Now go forth and calculate! And remember, if you get stuck, there are plenty of resources online and even – gasp – actual textbooks. Happy stressing! (Pun intended, of course.)