Ever wonder if that cool plastic toy your kid got from a vending machine, or maybe even a component in your car, could have sprung to life from a 3D printer? It's a fascinating thought, isn't it? The idea of creating objects, seemingly from thin air, is something straight out of science fiction, but 3D printing, also known as additive manufacturing, is very much a reality. And one of the most common questions surrounding this technology is: just how strong are these 3D printed creations?

At its core, 3D printing is a process of building up an object layer by layer, using materials like plastics, metals, ceramics, and even composites. This is different from traditional manufacturing, where material is often cut away to achieve the desired shape. The beauty of 3D printing lies in its ability to create incredibly complex geometries, customize designs easily, and produce objects on demand, often reducing waste and lead times. This makes it incredibly valuable for prototyping, creating bespoke parts, and even producing end-use products.

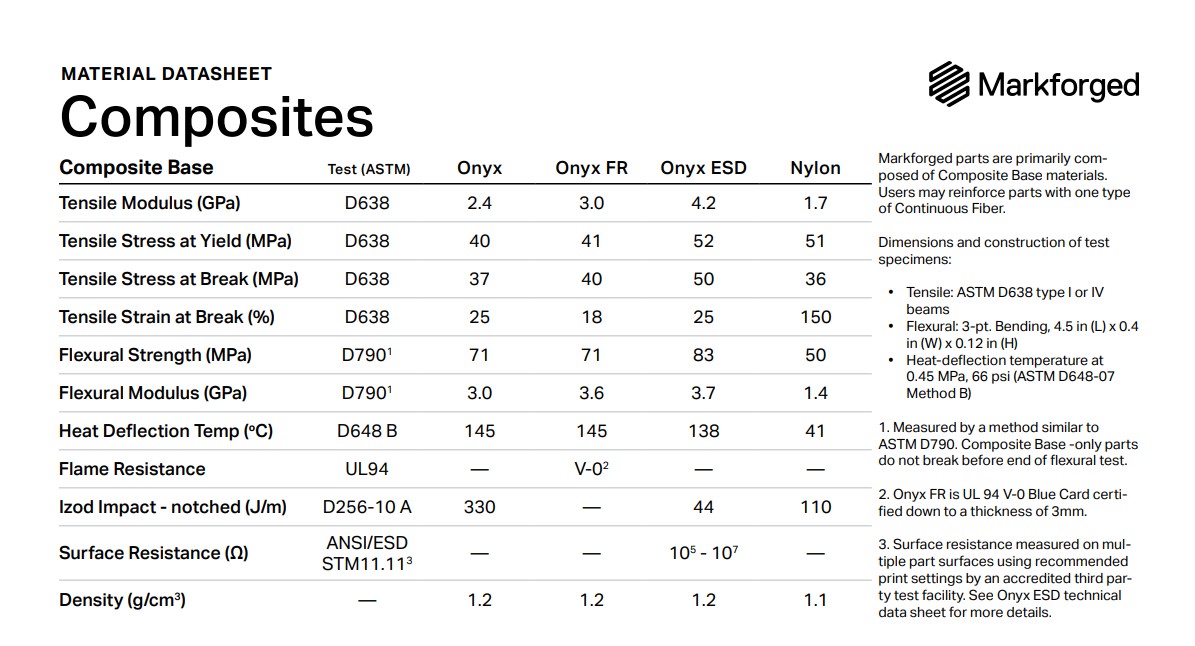

But let’s get back to the strength question. The truth is, the strength of a 3D printed object isn’t a simple yes or no answer. It's more like, "it depends!" It depends on a variety of factors including the material used, the printing technology, the design of the object, and even the printer settings. For example, a part printed with high-performance nylon using a technique called Selective Laser Sintering (SLS) will be significantly stronger than a toy printed with basic PLA plastic using a Fused Deposition Modeling (FDM) printer – the type you might find in a school classroom. Think of it like comparing a steel beam to a plastic straw – both serve a purpose, but their strength characteristics are vastly different.

You see 3D printing popping up everywhere these days. In education, students are designing and printing everything from simple gears to complex architectural models, learning about design, engineering, and material science in a hands-on way. In daily life, you might encounter 3D printed phone cases, custom-fitted insoles for your shoes, or even replacement parts for household appliances. Furthermore, 3D printing has found applications in more demanding fields like aerospace, where lightweight and strong components are crucial, and in medicine, where custom prosthetics and surgical guides are being created.

So, how can you explore the world of 3D printed strength yourself? One simple way is to find a local maker space or library that offers 3D printing services. Experiment with different materials and designs. You could even design and print a simple object, like a small hook or a bracket, and test its strength by gradually adding weight. Observe how the object fails – does it bend, break, or delaminate (layers separate)? You can also find plenty of online resources and communities dedicated to 3D printing. These forums are a great place to learn from experienced users and find inspiration for your own projects.

Don't be intimidated! The world of 3D printing is constantly evolving, with new materials and technologies emerging all the time. While it might not replace traditional manufacturing entirely, it's undeniable that 3D printing is transforming the way we design, create, and interact with the physical world. And who knows, maybe one day you'll be designing and printing your own strong and innovative creations!