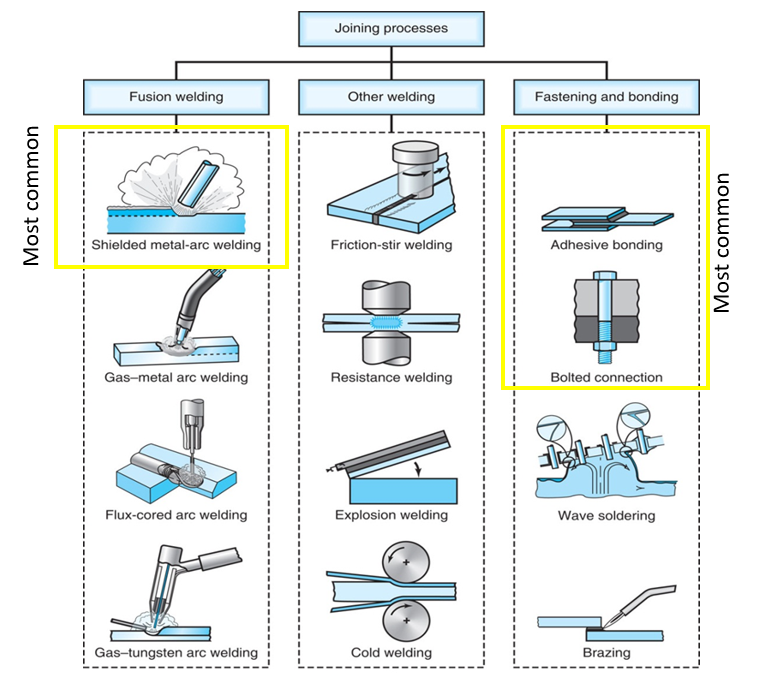

Hey there! So, you're thinking about gluing sheet metal to sheet metal, huh? Interesting choice! It's not always the first thing that pops into your head, is it? Like, welding is the usual go-to, right? But hold on a sec… sometimes glue is actually the *perfect* answer.

I mean, let's be real. Welding can be a bit… intense. Sparks flying, the smell of burning metal (which, okay, some people *love*, I get it!), all that gear. And let's not even talk about the skill involved. Can you weld? I can… sort of. Okay, mostly I make abstract art out of melted metal. Not exactly structural integrity, you know?

But gluing? Now that's something most of us can handle. Think of it like adult arts and crafts! So, let's dive into the world of adhesive metal bonding. Are you ready for this? I hope so!

Why Glue Sheet Metal? Seriously?

Okay, valid question. Why *would* you glue metal? Well, for starters, it's often easier and safer than welding or riveting. No heat, no sparks, no specialized equipment beyond, like, maybe a clamp or two. Plus, no worries about warping the metal, which is a HUGE bonus if you're working with thin stuff.

And get this: glue can actually provide a stronger bond than welding in some situations! Say what?! It's true! Especially when you need to distribute stress evenly across a large surface. Think about it: a weld is concentrated in one spot, while glue spreads the load. Smart, right?

Then there's the whole aesthetic thing. No weld lines! A smooth, clean finish. Perfect if you're going for a sleek, modern look. Although, if you’re *into* the industrial look, maybe the weld lines are your jam. To each their own!

Choosing the Right Glue: The Sticky Situation

Not all glues are created equal, my friend. Slapping some Elmer's on there just isn't going to cut it. Trust me, I’ve tried (not with metal, but… well, never mind!). You need something with some serious oomph.

So, what's the magic sauce? Epoxy adhesives are generally your best bet. They're incredibly strong, durable, and resistant to all sorts of nastiness like heat, chemicals, and moisture. Plus, they fill gaps nicely. You know, in case your metal isn't perfectly flat (and let's be honest, is anything *ever* perfectly flat?).

Polyurethane adhesives are another good option, especially if you need something with a bit of flexibility. They're also great for bonding dissimilar metals, which can be a problem with some other adhesives. You wouldn't want your metals arguing with each other, would you?

Also, keep an eye out for structural acrylic adhesives. These guys cure super fast, which is awesome if you're impatient like me. Just be sure you know what you're doing before you squeeze that trigger!

Prep Work: The Key to a Solid Bond

Okay, this is the boring part, but it's *crucial*. You can't just slap glue on dirty, greasy metal and expect it to hold. That’s just…asking for trouble. Think of it like painting: the better the prep, the better the finish.

First, you gotta clean the surfaces. Get rid of any dirt, rust, oil, or other contaminants. Use a solvent like acetone or isopropyl alcohol. And wear gloves! Nobody wants greasy fingerprints messing things up. Plus, who knows what's lurking on that metal? Yuck.

Next, roughen up the surfaces a bit. This gives the glue something to grab onto. Sandpaper, a wire brush, even a quick blast with a sandblaster will do the trick. Just don't go overboard! You're not trying to sculpt the metal, just create a little texture.

Finally, give it one last wipe down with your solvent of choice to remove any dust or debris from the sanding. Now you're ready to get sticky!

Applying the Glue: Get it Right!

Read the adhesive manufacturer’s instructions! Seriously! Every glue is a little different, and you don't want to mess things up by ignoring the directions. It's like ignoring the recipe when baking a cake. Disaster awaits!

Apply the glue evenly to both surfaces. Don't glob it on! A thin, consistent layer is key. Think of it like spreading peanut butter. Too much, and it just squishes out the sides. Gross.

Clamp the pieces together while the glue cures. This ensures good contact and prevents movement. Use clamps, weights, whatever you've got! Just make sure it's secure.

And be patient! Let the glue cure for the recommended time. Don't rush it! You want a strong, durable bond, right? Good things come to those who wait… and properly glued sheet metal, apparently.

So, Should You Glue It?

Well, that depends! Gluing sheet metal has its advantages, but it's not always the best solution. Consider the application, the load, and the environment. If you need a super strong, permanent bond, welding might still be the way to go. But for many projects, glue can be a fantastic, easy, and even superior alternative.

Give it a try! You might be surprised at how well it works. And hey, if it doesn't work out? Well, that’s what duct tape is for. Just kidding! (Mostly…)