Alright folks, let's talk welding! Ever heard of flux core wire with shielding gas? Maybe you have, maybe you haven’t. But trust me, even if you're not a professional welder, this stuff is pretty darn cool. Think of it as the Swiss Army Knife of welding wires – versatile, reliable, and ready to tackle a bunch of different jobs.

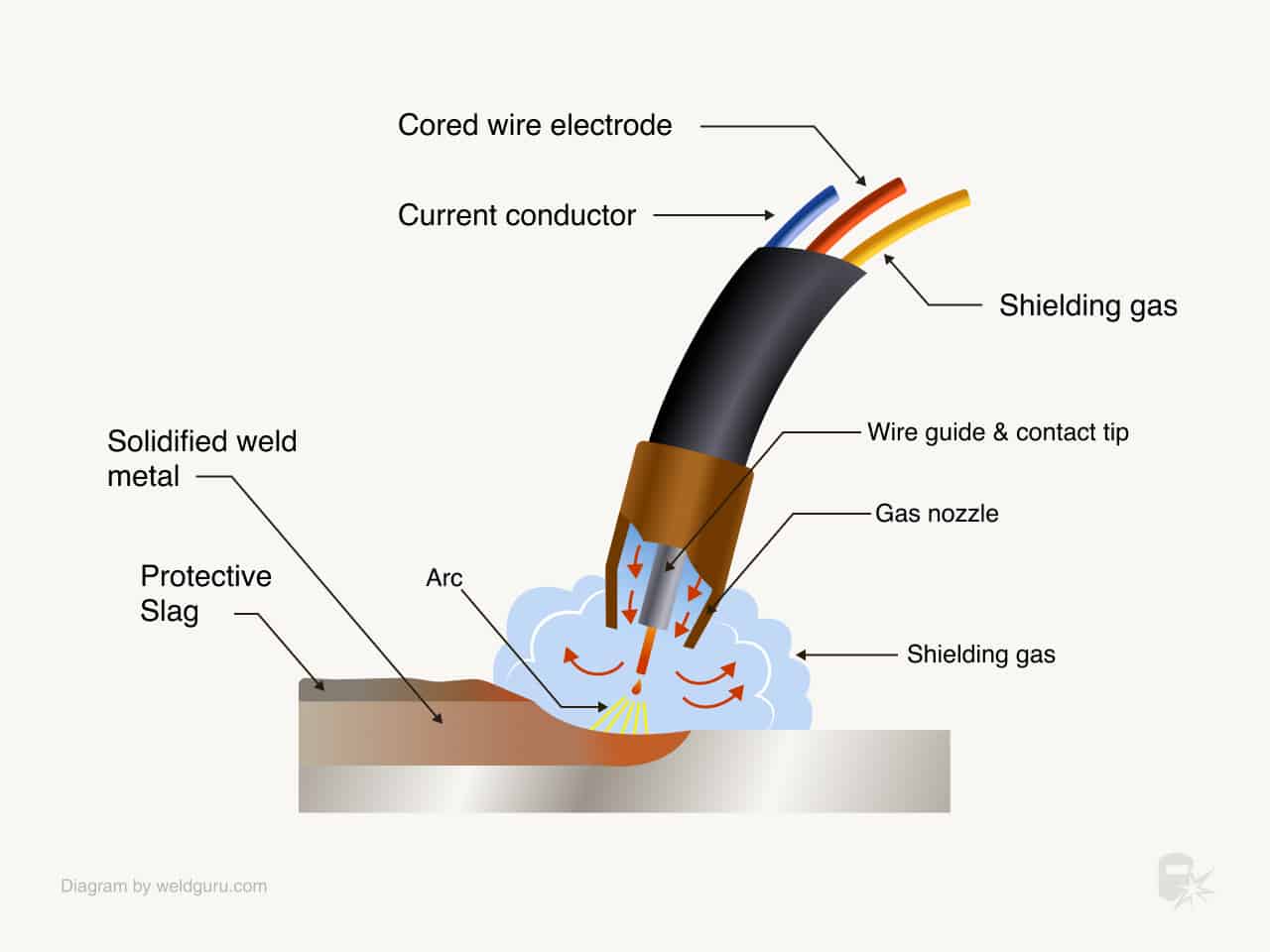

So, what exactly *is* flux core with shielding gas? Well, at its heart, it's a type of welding wire. But unlike your standard MIG wire, it has a special filling inside called flux. Now, normally flux core wires have flux that act as a shield, but the use of shielding gas creates the best of both worlds.

Now, why is that so awesome? Glad you asked! It all boils down to cleaner, stronger welds. Imagine you're baking a cake, right? You need all the right ingredients in the right proportions to get that perfect fluffy texture and delicious taste. Welding is kind of similar. You need to protect the molten metal from the air around it to prevent contamination. Contamination leads to weak, porous welds that are about as sturdy as a house of cards in a hurricane. No one wants that!

The Dynamic Duo: Flux and Gas

Okay, so the flux inside the wire does a lot of the heavy lifting, shielding the weld pool from atmospheric nasties like oxygen and nitrogen. It’s like a tiny bodyguard for your weld. It consumes oxides and produces a gas to help with the shielding. But here's where the shielding gas comes in. It's like having a backup bodyguard for the bodyguard! Using a shielding gas like CO2 or a mixed gas gives you an extra layer of protection, resulting in a weld that's even cleaner, stronger, and less prone to defects.

Think of it like this: flux is your initial defense, like a good sunscreen. But the shielding gas is like wearing a full hazmat suit on top of that sunscreen. You're really serious about protecting that weld!

But why not just use regular MIG wire with shielding gas? Another excellent question! While MIG (Gas Metal Arc Welding) is fantastic, flux core with shielding gas excels in certain situations. Particularly when welding thicker materials, or materials that might be a little dirty or rusty. The flux helps to clean the metal and provide a more stable arc, while the shielding gas ensures a clean weld.

When Does It Shine?

So, where does this method really shine? Here are a few scenarios:

- Thick Metal: Welding thick steel plates? Flux core with gas is your friend. It provides good penetration and deposition rates.

- Outdoors: It is a great alternative to stick welding, it's less susceptible to wind compared to regular MIG welding but more resistant than gasless fluxcore. The shielding gas provides added protection from the elements.

- Less-Than-Perfect Metal: Got some rusty or painted metal you need to weld? Flux core with gas can often handle it better than other processes. The flux helps to burn through the contaminants.

- Structural Welding: For projects that need serious strength and reliability, flux core with gas is a great option.

Imagine you're building a sturdy metal fence. You want something that's going to last for years, right? Using flux core wire with shielding gas gives you that extra peace of mind, knowing that your welds are as strong and durable as possible.

The Cool Factor

Beyond the practical benefits, there's just something cool about flux core welding with shielding gas. Maybe it's the controlled arc, or the consistent weld beads you can achieve. Or maybe it's just the satisfaction of knowing you're creating something strong and lasting. Whatever it is, it's a welding process that many experienced welders swear by.

And let's be honest, watching those sparks fly and seeing a clean, strong weld emerge? That's just plain satisfying, isn't it?

So, next time you're thinking about a welding project, consider giving flux core wire with shielding gas a try. You might just find your new favorite welding process. Who knows, maybe you'll even become the "Welding Wizard" of your neighborhood!

Just remember to always prioritize safety – wear your helmet, gloves, and other protective gear. Happy welding!