Hey there, welding buddy! Ever heard someone say you *absolutely* need shielding gas for every type of welding? Well, let me let you in on a little secret: that's not always the case. Let's talk about Flux-Cored Arc Welding, or FCAW for short. It's a cool process, and guess what? Sometimes, it can ditch the whole gas thing altogether!

Think of FCAW like this: you've got your welding gun, your wire is feeding through, and *zap* – you're making sparks fly and joining metal together. Now, in some welding processes like MIG (GMAW), you definitely need a shielding gas – usually argon, CO2, or a mix – to protect the weld pool from the atmosphere (oxygen, nitrogen, etc.). These atmospheric contaminants can cause porosity, weak welds, and basically make your project look like it lost a fight with a cheese grater. No one wants that!

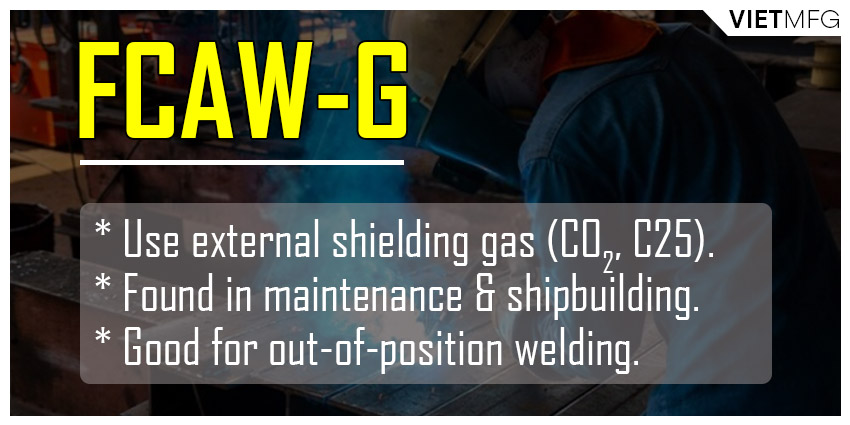

But FCAW? It's a bit of a rebel. You see, there are actually two main types of FCAW: gas-shielded (FCAW-G) and self-shielded (FCAW-S). The gas-shielded version is pretty similar to MIG – you still need that external gas supply. But the self-shielded variety? That's where the magic happens.

Self-Shielded FCAW: The Gas-Free Hero

Okay, so how does self-shielded FCAW work without a gas cylinder strapped to your back? It's all in the wire! This special wire is filled with flux, a granular compound that contains all sorts of goodies. When the arc forms, the flux melts and creates its own shielding gas as it burns. Talk about self-sufficient!

This "internal" shielding gas protects the weld pool just like an external gas would, keeping out those pesky atmospheric contaminants. Plus, the flux also deoxidizes the weld metal, scavenges impurities, and can even add alloying elements to improve the weld's properties. It's like a Swiss Army knife for welding!

Think of it this way: the flux is like having a tiny, portable atmosphere generator right inside your welding wire. Pretty neat, huh? It’s like the wire is saying, "Don't worry, I got this!"

Why Go Gas-Free? The Perks of Self-Shielded FCAW

So, why would you choose self-shielded FCAW over the gas-shielded kind? Well, there are a few key advantages:

- Portability: No gas cylinder means you can weld practically anywhere! Perfect for outdoor work, on-site repairs, or any situation where lugging around a heavy gas tank is a pain. Imagine climbing scaffolding with a gas bottle. Yeah, no thanks!

- Wind Resistance: External shielding gases can be easily blown away by the wind, leading to porosity and weak welds. Self-shielded FCAW is much more resistant to windy conditions. Think of it as the wind-resistant welding option!

- Simpler Setup: Less equipment means less to go wrong. No regulators, no hoses, just plug in your machine and weld! You can spend less time setting up and more time creating.

Of course, there are some downsides too. Self-shielded FCAW typically produces more spatter than gas-shielded, and the slag (the residue left behind by the flux) needs to be chipped away after welding. But hey, a little extra cleaning is a small price to pay for the freedom of welding without gas!

Also, self-shielded wire tends to be more expensive than solid MIG wire. It's like paying a premium for the convenience of that built-in shielding. But when you factor in the cost of gas, regulators, and the hassle of transporting cylinders, it can often even out, especially on smaller projects.

When To Use Self-Shielded FCAW

Self-shielded FCAW is a great choice for:

- Outdoor welding: Construction sites, farms, or anywhere the wind is a factor.

- On-site repairs: When portability is essential.

- Thick materials: Self-shielded FCAW is generally better suited for thicker materials than MIG welding.

- Dirty or rusty materials: The flux can help clean the weld area and produce sound welds even on less-than-perfect surfaces. (But always clean if you can!)

Important note: always check the manufacturer's recommendations for the specific wire you're using. Different wires are designed for different applications and thicknesses.

Wrapping It Up: Go Forth and Weld!

So there you have it! FCAW, in its self-shielded form, is a fantastic option for welding without the need for a pressurized shielding gas. It's portable, wind-resistant, and relatively easy to use. While it might not be the perfect choice for every situation, it's a valuable tool to have in your welding arsenal. Don't be afraid to give it a try!

Now go out there, fire up your welder, and create something amazing. And remember, even if you encounter a few hiccups along the way, every weld is a learning opportunity. Keep practicing, keep experimenting, and keep having fun! You got this! Happy welding!