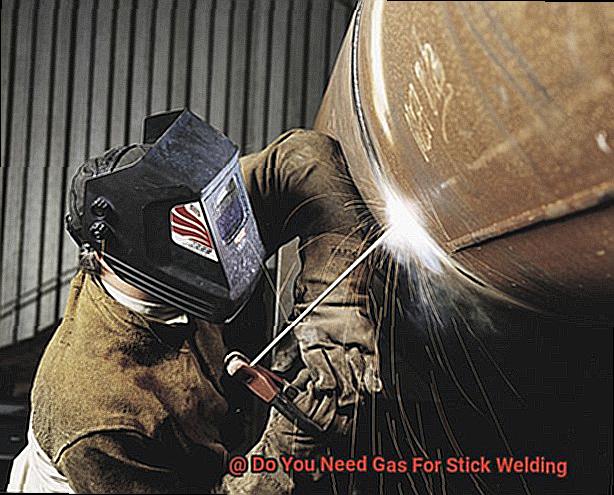

Welding. The word itself might conjure up images of sparks flying, heavy machinery, and skilled artisans crafting metal masterpieces. But have you ever stopped to wonder about the science behind it all? Specifically, when you see someone stick welding, also known as Shielded Metal Arc Welding (SMAW), do they need to drag out those cumbersome gas cylinders? The answer, surprisingly, is often no! And understanding why is not only fascinating but can also open up a whole new world of DIY possibilities.

Why is this important? Well, imagine you’re a hobbyist working on a project in your garage, or a farmer needing to make a quick repair in the field. Dragging around heavy gas cylinders and setting up complex gas delivery systems can be a real hassle. Stick welding's portability and relative simplicity make it an incredibly useful skill to learn. It cuts through the complication and allows you to focus on the art and science of joining metal.

The real magic behind stick welding lies in the electrode. This isn’t just a piece of metal; it’s a consumable rod coated in a flux. When you strike an arc (create an electrical connection) between the electrode and the workpiece, the heat melts both the electrode and the metal you’re joining. But here's the kicker: as the flux coating melts, it releases a shielding gas. This gas acts like a protective blanket, preventing atmospheric contaminants like oxygen and nitrogen from interacting with the molten metal. These contaminants can weaken the weld, causing porosity (tiny holes) and reducing its overall strength. So, in essence, the gas is created on the spot, right where it's needed, eliminating the need for an external gas supply.

Think about it: farmers use stick welding to repair farm equipment in the field. Construction workers use it to weld structural steel. Even artists use it to create metal sculptures. Because it's so versatile and doesn't require external gas, it's a popular choice for outdoor applications where gas cylinders would be impractical or impossible to use. Trade schools and vocational programs often teach stick welding as a foundational skill because of its broad applicability and relatively low initial equipment cost.

Want to dip your toes into the world of stick welding? Here are a few simple ways to explore it: first, watch some videos online. There are tons of excellent tutorials available that cover the basics of equipment setup, striking an arc, and running a bead (creating a weld). Second, consider taking a short introductory class at a local community college or trade school. Hands-on experience with a qualified instructor can make a huge difference. Finally, invest in a basic stick welding machine, some electrodes, and essential safety gear (welding helmet, gloves, and protective clothing). Remember, safety is paramount! Start with scrap metal and practice your technique. Don’t be afraid to experiment and learn from your mistakes. Stick welding, while requiring practice, is a rewarding skill that can empower you to fix, build, and create amazing things.

So, the next time you see someone stick welding, remember that they're not just melting metal together; they're harnessing the power of chemistry and electricity to create strong and lasting bonds, all without the need for an external gas supply. It's a testament to the ingenuity and practicality of this enduring welding process.